Transmission system of threading machine

A technology of transmission system and threading machine, which is applied in the field of transmission system, can solve problems such as easy loose clamping of rear chuck threading, and achieve the effects of expanding the application range of processing, simple operation and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

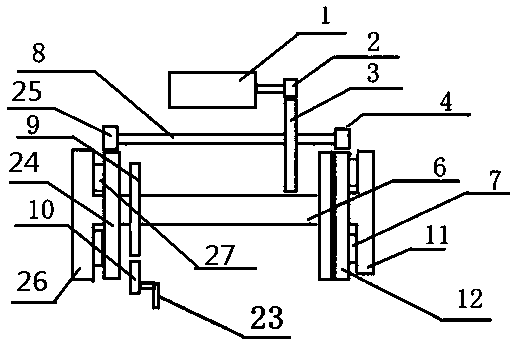

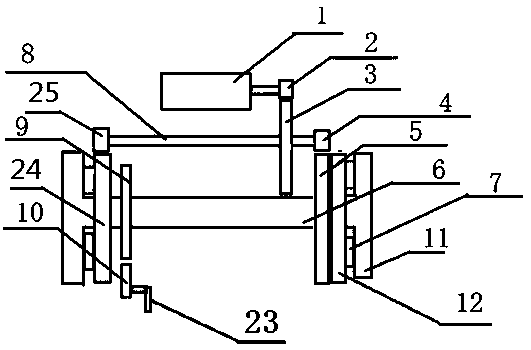

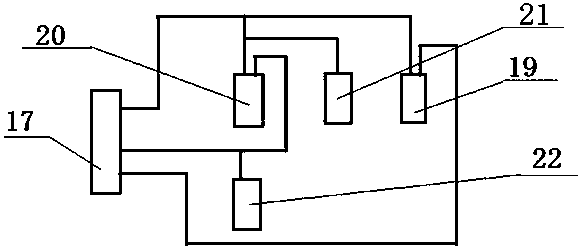

[0025] The present invention will be further described below in conjunction with the accompanying drawings. In each of the following embodiments, the power reduction transmission system refers to the reduction box of the prior art, the driven shaft 8 is the output shaft of the reduction box, and the driving wheel 4 on the driven shaft 8 is the same as the second driving wheel 25, collectively referred to as driving wheel;

[0026] In the present invention, chuck is a general term for front and rear chucks;

[0027] Plane spiral is the general designation to plane spiral 12, second plane spiral 24;

[0028] The chuck body is a general term for the chuck body 11 and the chuck body 26;

[0029] Jaw is a general term for jaw 7 and jaw 27;

[0030] The collective term refers to the unified term for parts with the same performance and parameters;

[0031] Partial rotation of the chuck refers to the rotation of the plane compasses of the front and rear chucks on the chuck body, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com