Wire feeding nozzle clamp for automatic wire feeding argon arc welding gun

A wire feeding and argon arc technology, which is applied to arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of wire feeding angle of wire feeding nozzle, inconvenient adjustment of wire feeding position, and unfavorable use of welding guns, and achieves compact structure, Simple adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

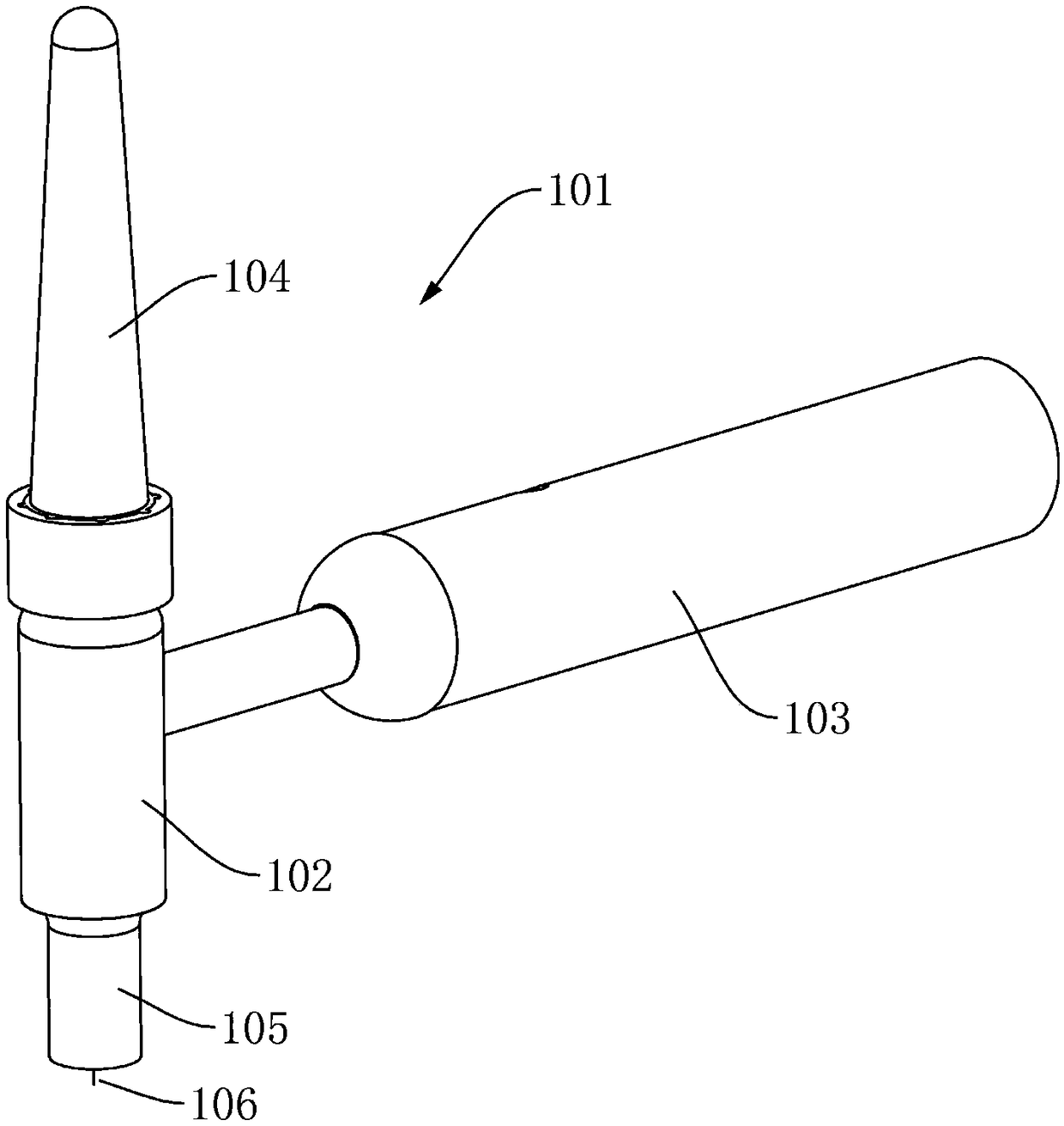

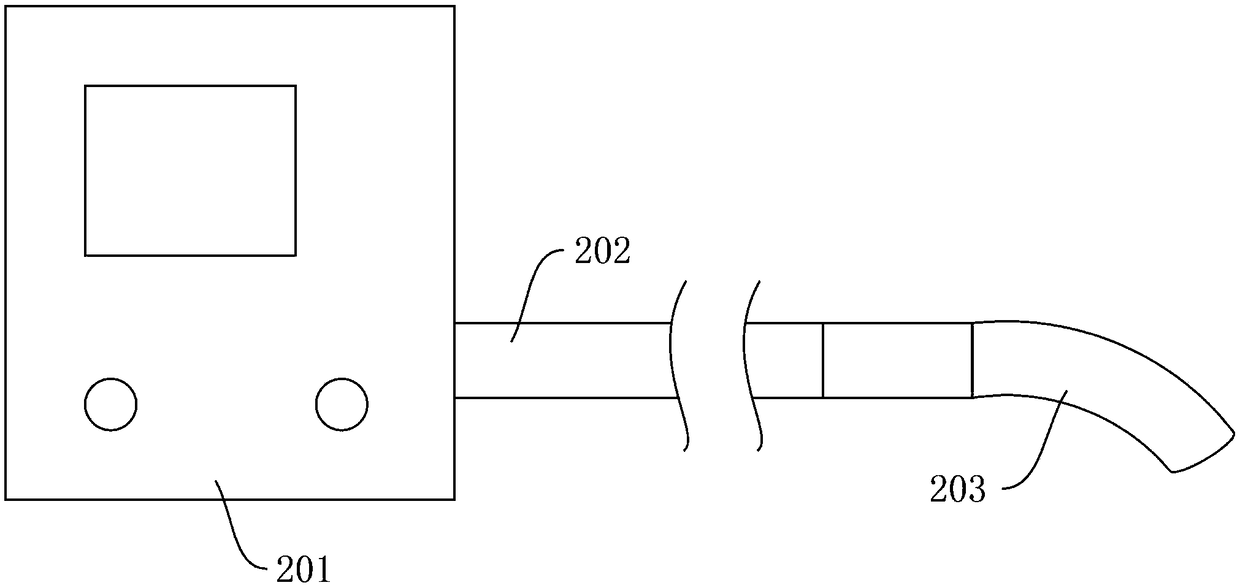

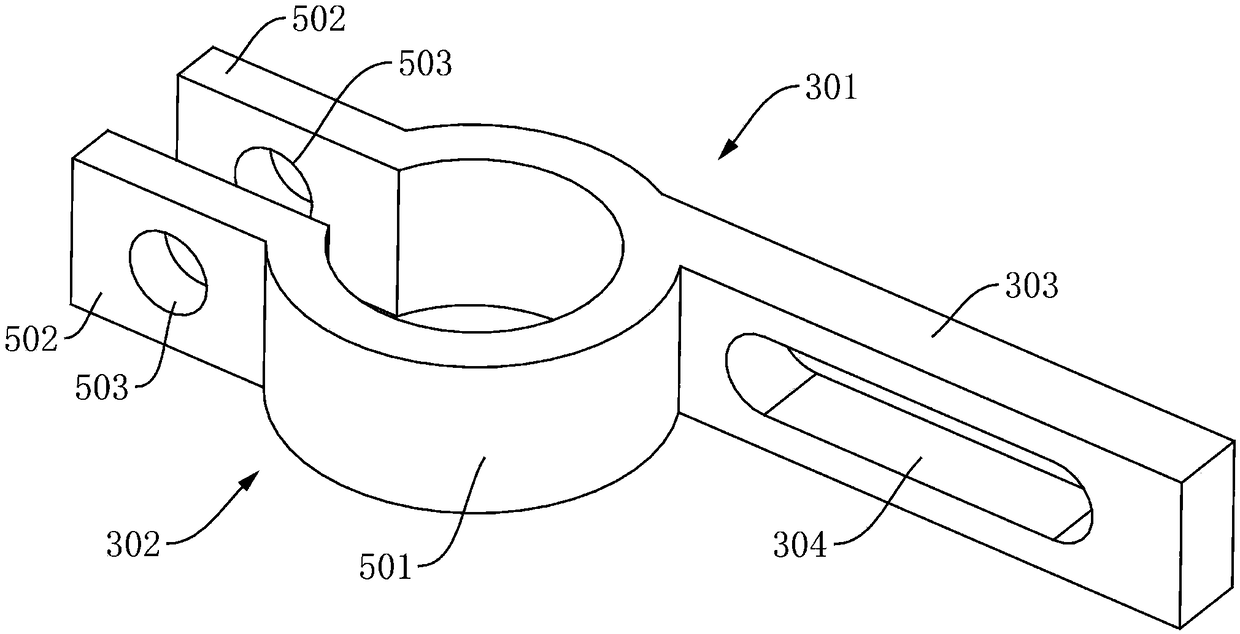

[0041] This embodiment provides a wire feed nozzle 203 clamp for an automatic wire-feeding argon arc welding torch 101, including a clamping part 1 301 and a clamping part 2 401, wherein the clamping part 2 401 is used to clamp the wire feed nozzle 203, the second clamping part 401 is detachably connected to the first clamping part 301, and can move and / or rotate relative to the first clamping part 301, the first clamping part 301 can rotate relative to the welding torch 101, and is used for clamping on Welding torch 101 on.

[0042] The clamping part one 301 in this fixture can rotate relative to the welding torch 101, so that the wire feeding nozzle 203 can rotate along the circumferential direction of the electrode 106 of the welding torch 101, thereby the installation position of the wire feeding nozzle 203 on the circumferential direction of the welding torch 101 electrode 106 can be adjusted (or called the installation angle), after the adjustment is in place, clamp and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com