Welding robot capable of preventing workpiece from shifting

A technology for welding robots and workpieces, applied in the field of robots, can solve the problems of scrapping finished parts, affecting eyesight, endangering physical health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

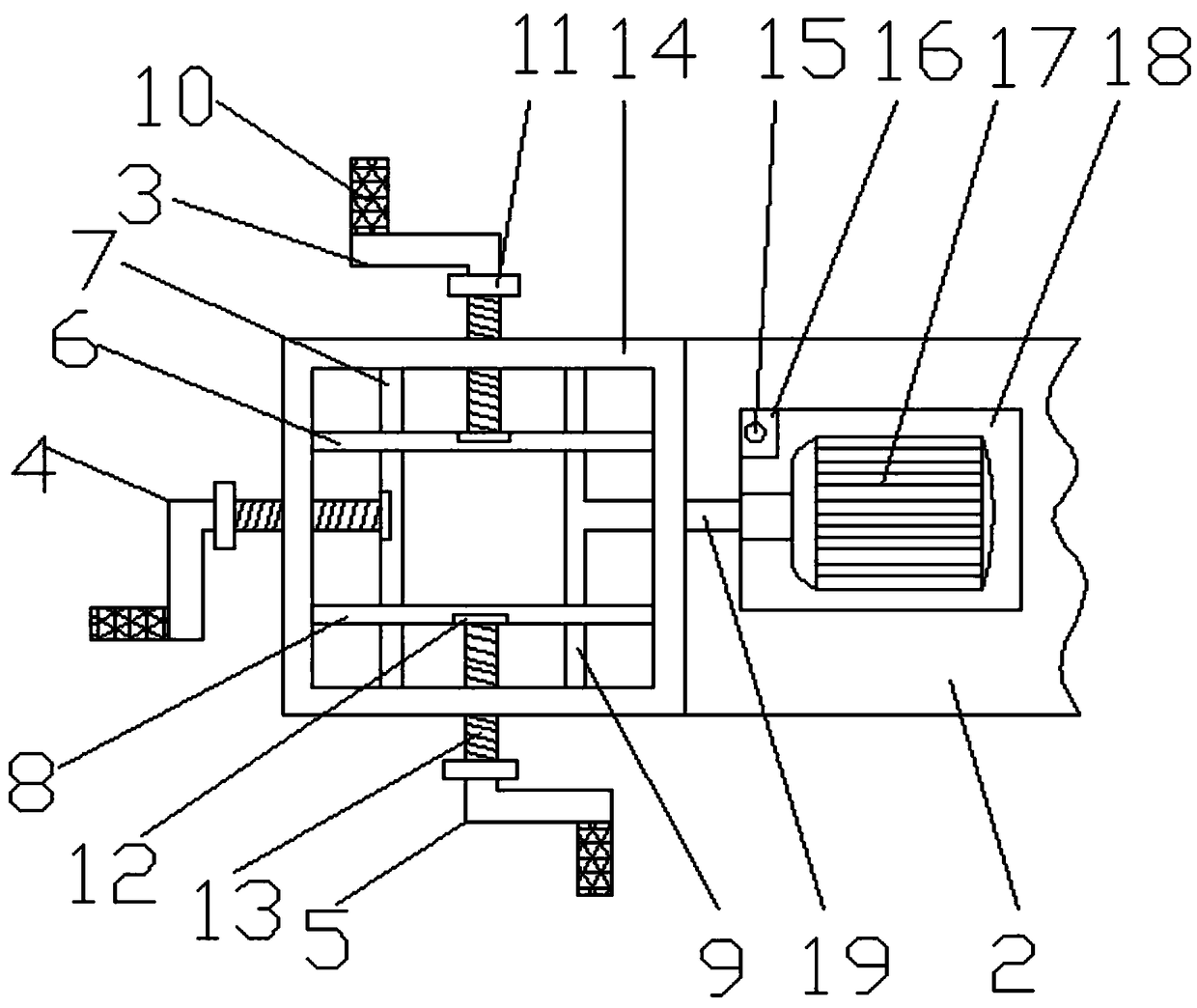

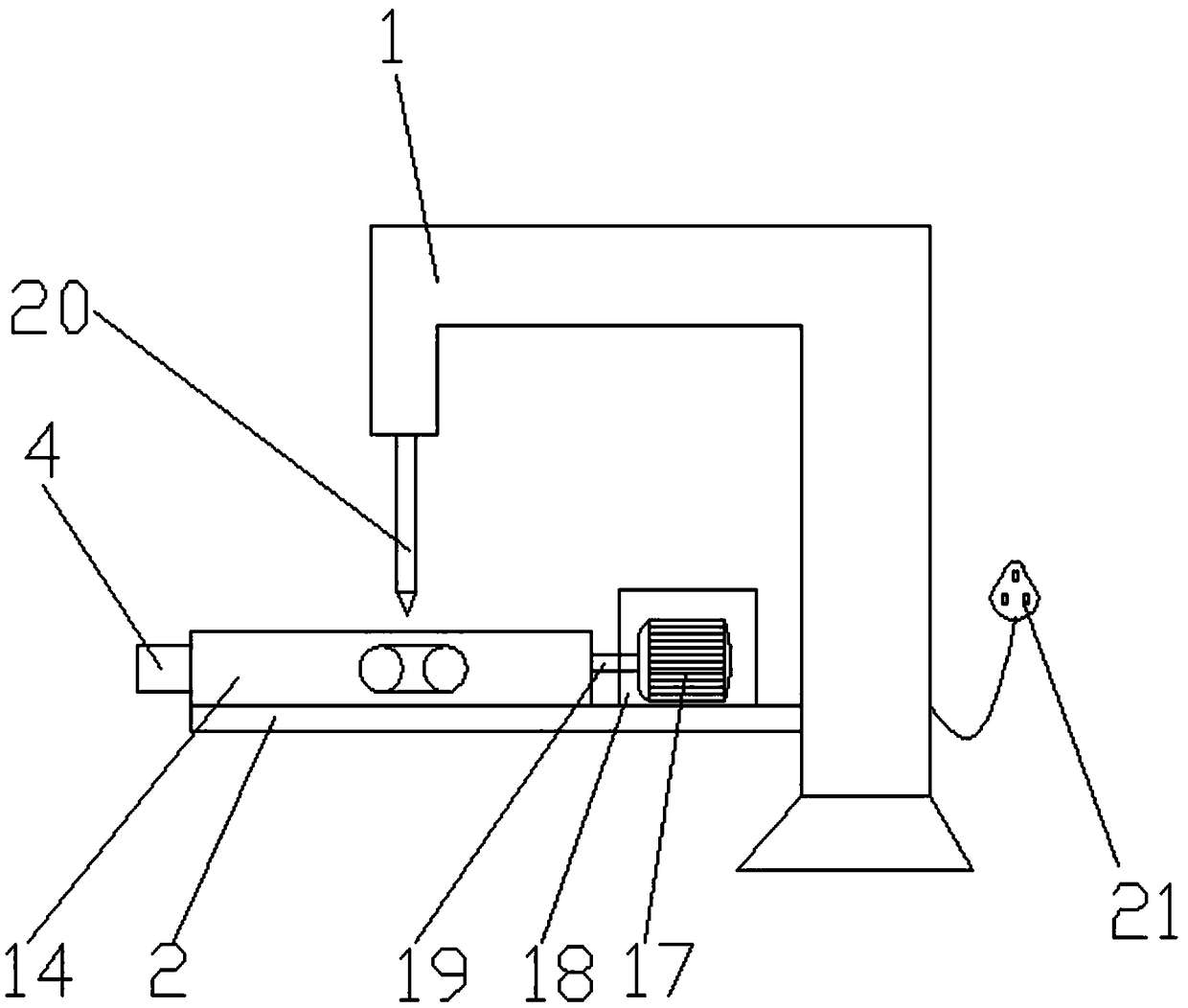

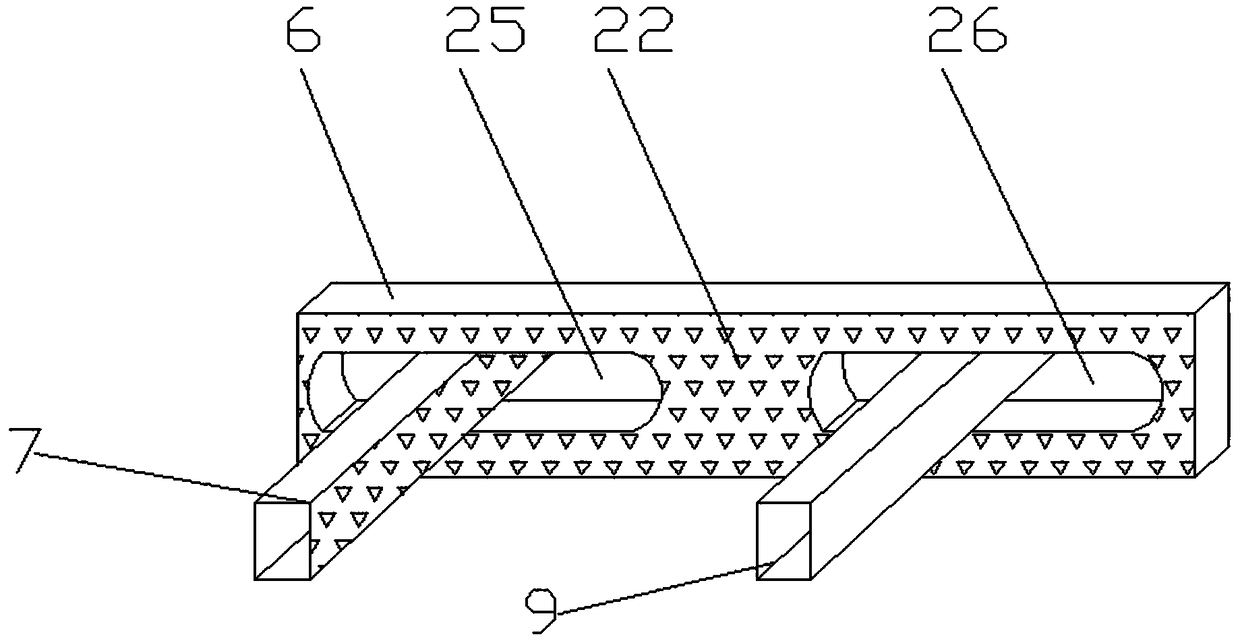

[0023] See Figure 1-4 , The present invention provides a technical solution: a welding robot capable of preventing the workpiece from shifting, including a body 1, a first hand crank 3, a second hand crank 4, and a third hand crank 5. The body 1 A welding rod 20 is connected to the left bottom of the upper end. A horizontal plate 2 is installed horizontally on the left side of the lower end of the machine body 1. The welding rod 20 is located directly above the horizontal plate 2, and a motor box 18 is installed at the right end of the upper surface of the horizontal plate 2. A push rod motor 17 is fixedly installed inside the motor box 18, a control panel 16 is installed at the left end of the top rear side of the motor box 18, and a clamp table 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com