Drying oven with high air volume for ink printing of intaglio printing press

A technology of drying oven and large air volume, applied in printing, printing presses, general parts of printing machinery, etc., can solve the problem of difficulty in rapid drying of printed matter, and achieve the effect of low cost, enhanced drying effect, and increased air speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

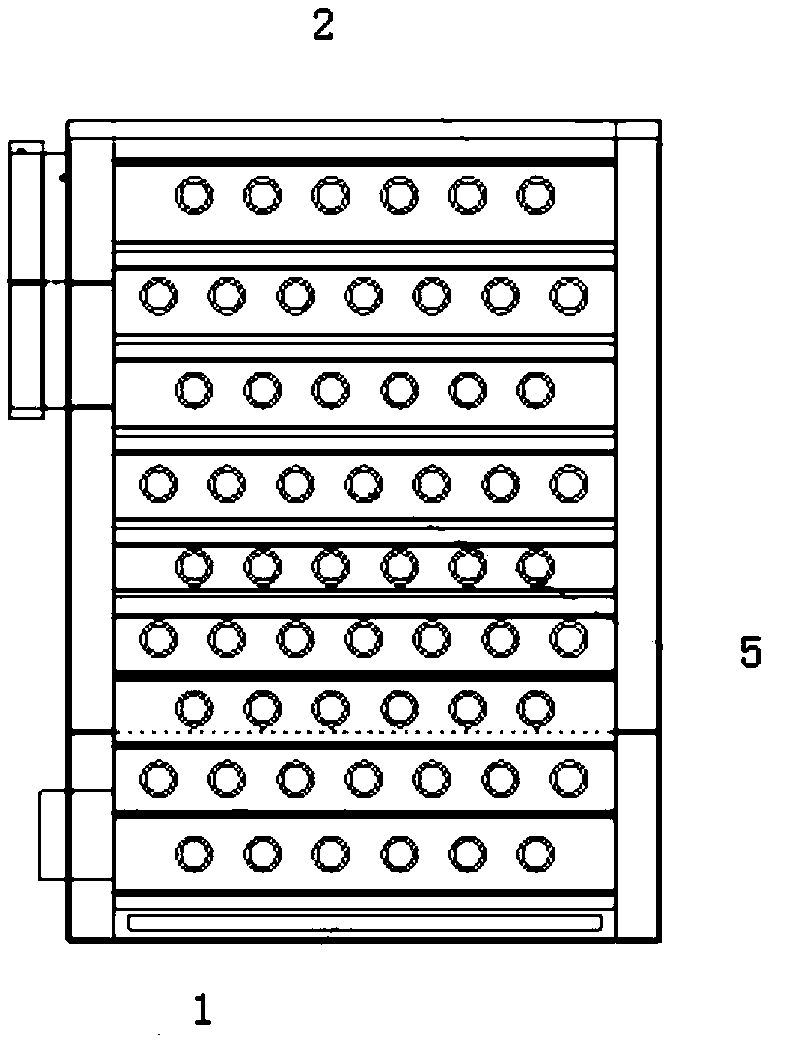

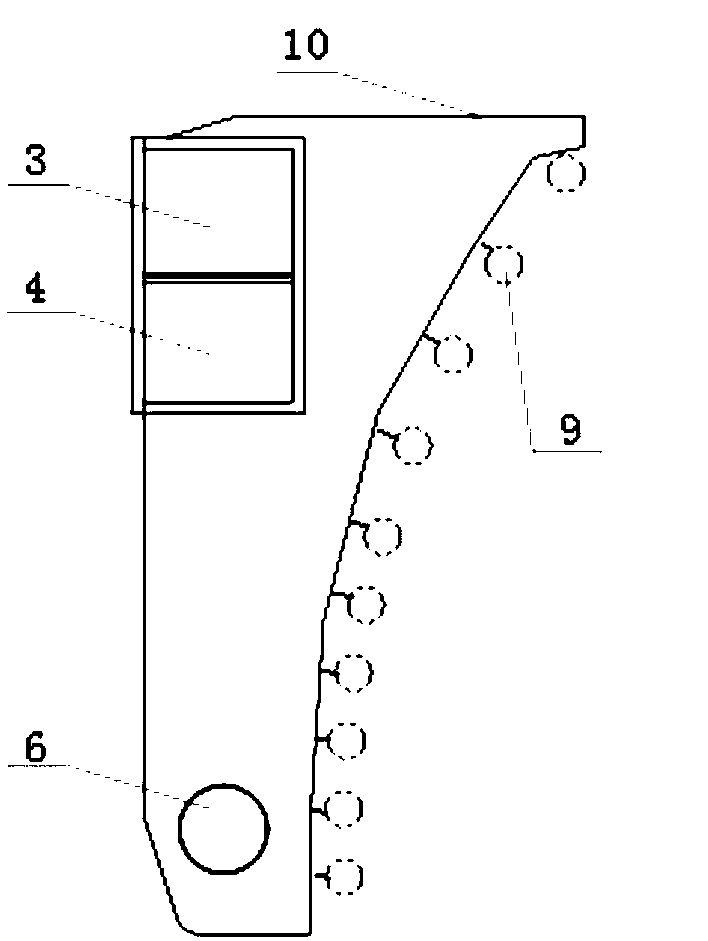

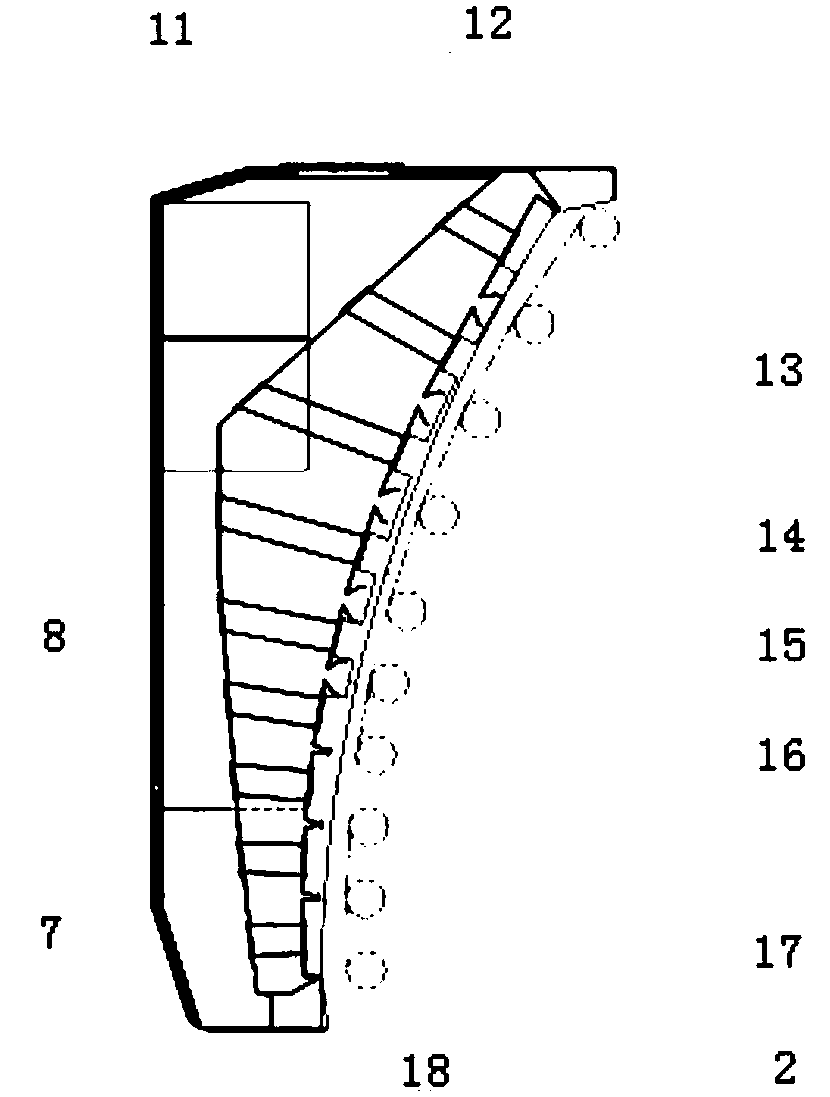

[0017] A kind of gravure printing machine water-ink printing high-air volume drying oven provided by the present invention, such as figure 1 As shown, it includes an oven shell 10, the lower bottom surface of the oven shell 10 is provided with a lower exhaust net 1, and the front of the oven shell 10 is provided with an inwardly concave arc-shaped drying panel, and several guide rollers 9 are horizontally arranged on the drying panel. The two ends of the material guide roller 9 are fixedly connected on the drying panel, there is a gap between the material guide roller 9 and the drying panel, and the material film 15 is fixed between the material guide roller 9 and the drying panel, and the material film 15 is fixed between the material guide roller 9 and the drying panel. The relative positions are provided with several blowing nozzles, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com