Holding type AGV

A clamping and connecting rod technology, which is applied in the direction of conveyor objects, motor vehicles, transportation and packaging, etc., can solve the problems of increased labor intensity, large weight and volume, waste of human resources, etc., and achieves significant shock absorption effect and load The effect of uniform distribution and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

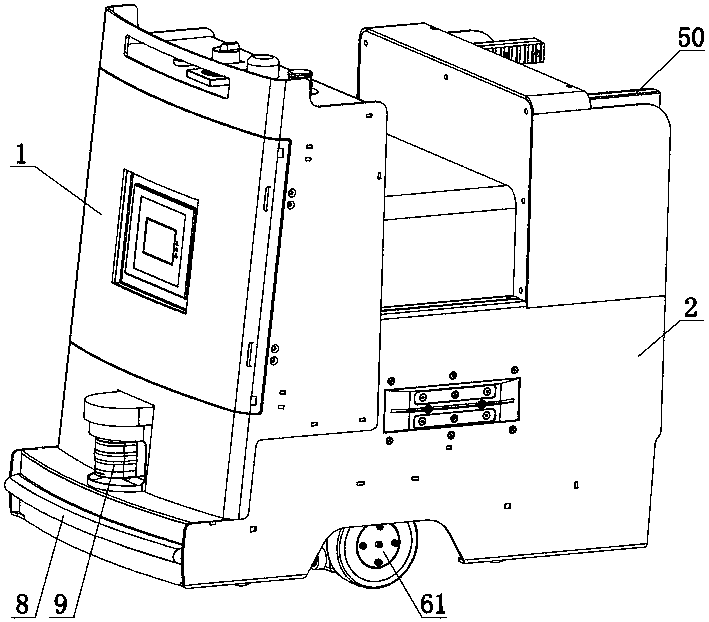

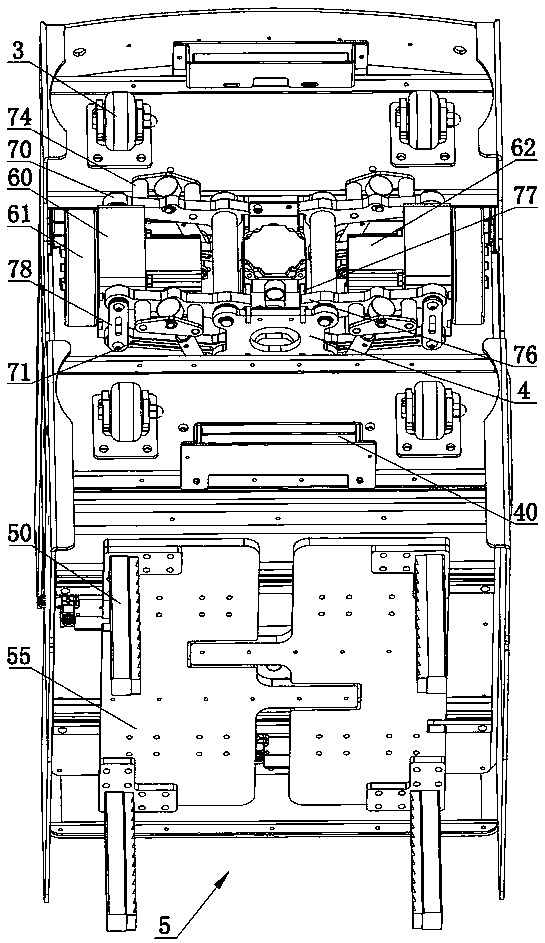

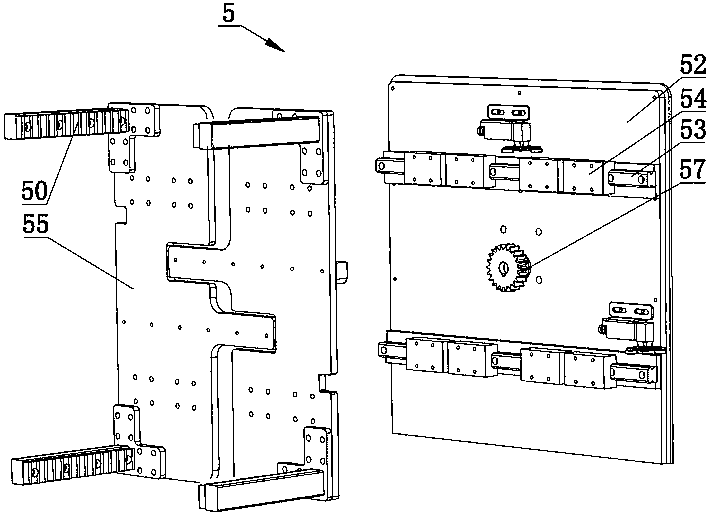

[0022] Such as Figure 1 to Figure 5 As shown, a tight-fitting AGV includes a front 1 and a rear 2. The front 1 and the rear 2 are each provided with at least one universal wheel 3, and also includes a base 4 located at the front 1 and a base 4 located at the rear. 2, the clamping device 5 includes a clamping part 50 and a first driving device 51 that drives the clamping part 50 to move back and forth, and both sides of the base 4 are provided with a power device 6 and a power device 6. The connecting rod device 7 of the device 6, the connecting rod device 7 includes a first connecting rod 70 and a second connecting rod 71 whose two ends are respectively hinged with the base 4 and the power device 6, and whose two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com