High-temperature steel grit heat insulation automatic discharging and feeding machine

A technology of automatic unloading and steel pellets, applied in the direction of conveyor objects, transportation and packaging, can solve problems such as heat loss, and achieve the effect of orderly unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

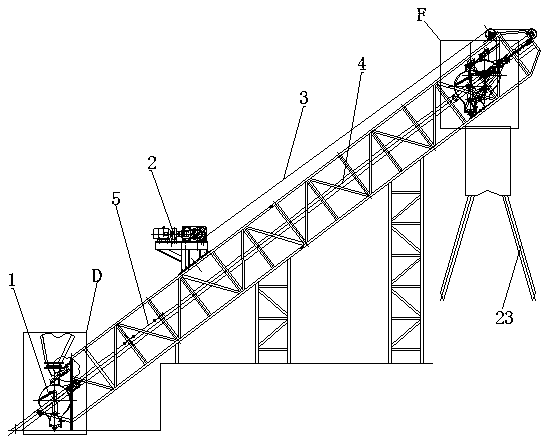

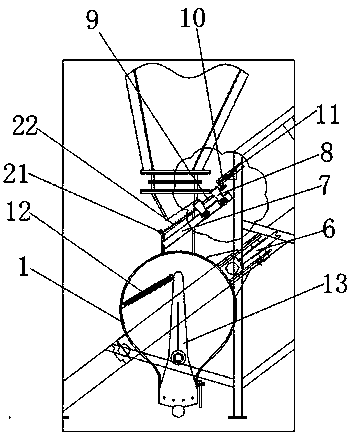

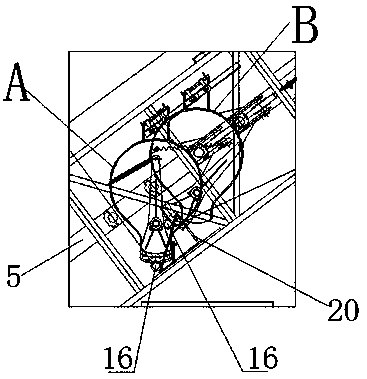

[0026] Refer to attached Figure 1-6 The shown high-temperature steel particle heat preservation automatic unloading and feeding machine includes a filling gun 1, a hoist assembly 2, a traction assembly 3 and a frame 4, the traction assembly 3 is a traction wire rope, and the frame 4 is arranged obliquely. The frame 4 is provided with a rising track along the inclined direction of the frame 4, and the injection gun 1 is slidably connected in the rising track, and an upper limit is also set on the rising track of the frame 4. position proximity switch, a lower limit travel switch, an upper limit travel switch and a safety protection travel switch, wherein the upper limit switch and the lower limit switch play a role ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com