Oblique-slip type feeding device

A technology of inclined sliding and inclined surface, applied in the field of inclined sliding feeding device, can solve the problems of unfavorable gripping jaws, reduce the production capacity of the rib cutting forming system, etc., and achieve the effect of improving feeding efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For the convenience of description, "left", "right" and figure 1 The left and right directions are the same.

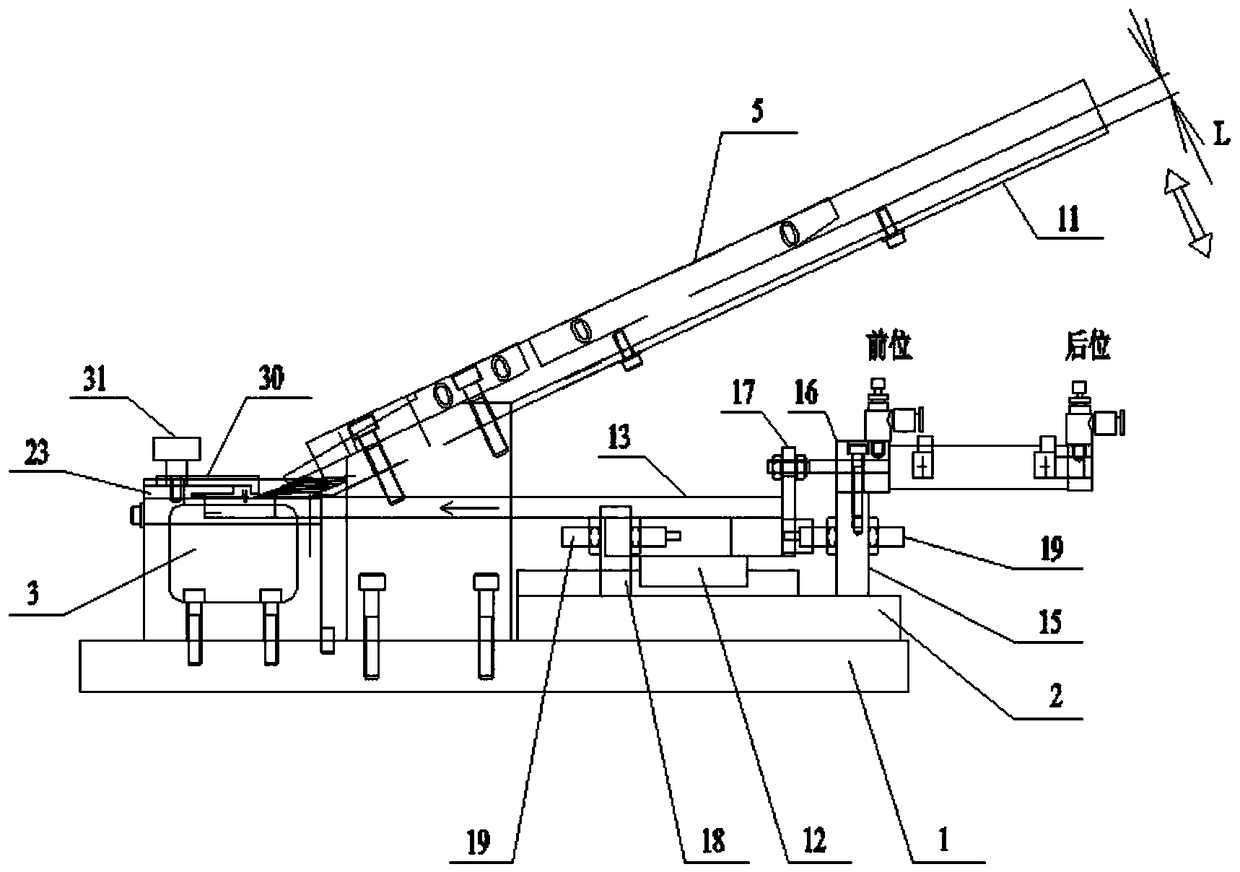

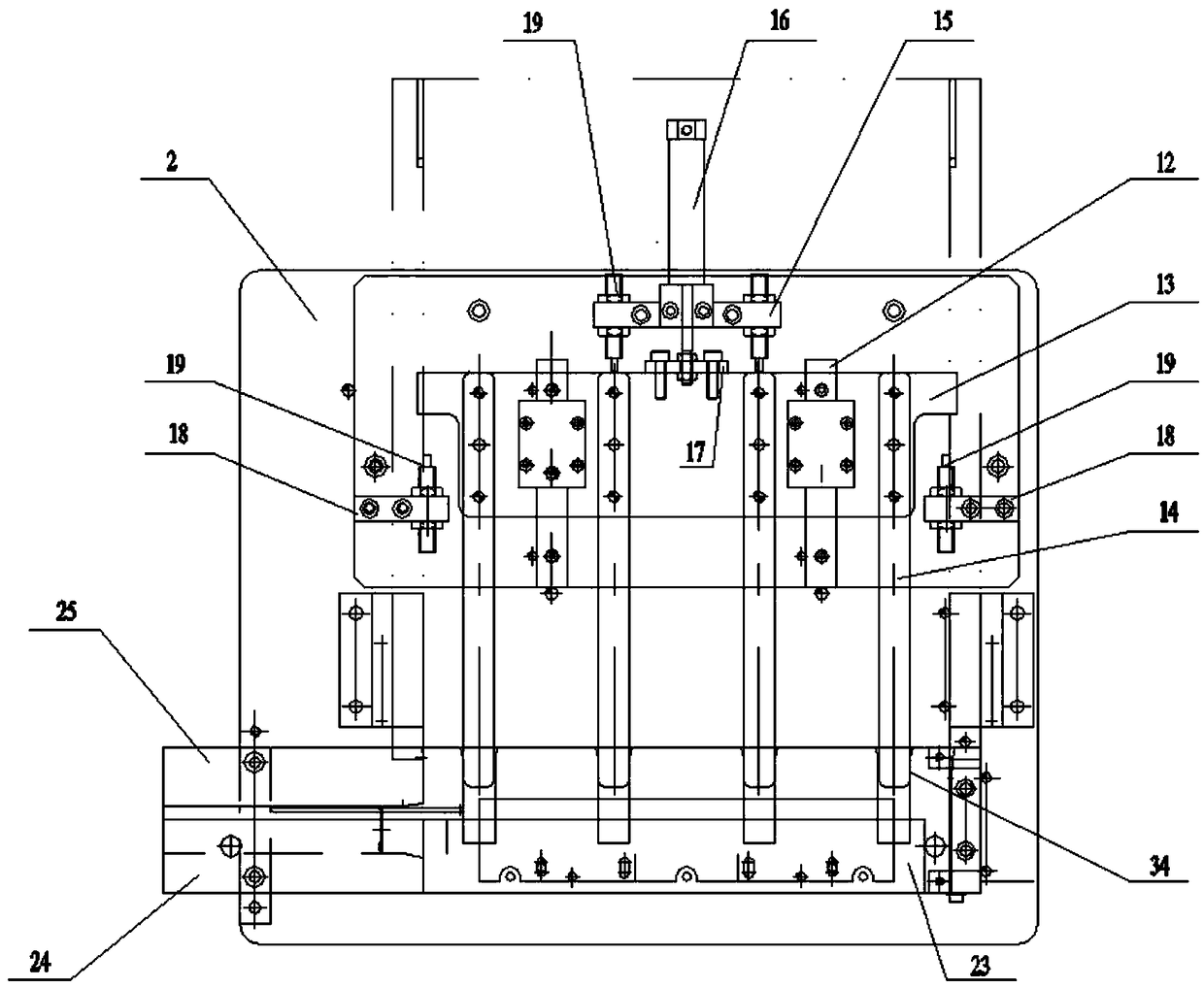

[0024] like Figure 1-5 As shown, a kind of slant-sliding feeding device comprises a bottom plate 1, a bottom plate 2, an inclined plane blanking mechanism, a product ejection mechanism and a feeding rail mechanism, the bottom plate 1 is the installation substrate of the whole device, and the bottom plate 2 2 is fixed on Bottom plate one 1 on.

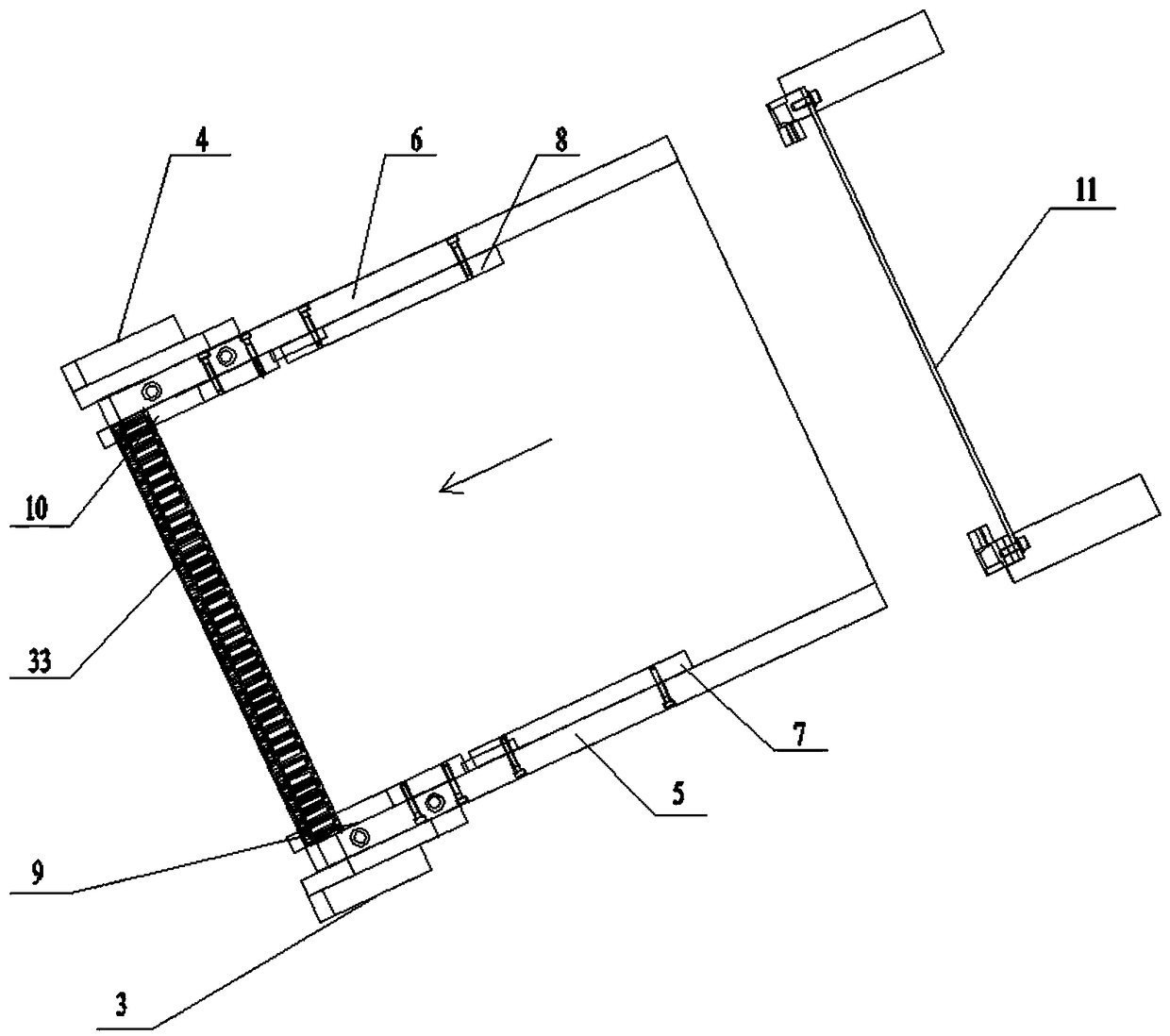

[0025] The function of the inclined-plane blanking mechanism is to store products and ensure that the products fall down from the inclined surface to the bottom of the inclined surface in sequence, including support seat one 3, support seat two 4, support plate one 5, support plate two 6, guide bar one 7, Guide bar two 8, guide bar three 9, guide bar four 10 and slide plate 11. The first support base 3 and the second support base 4 are positioned and fixedly installed on both sides of one end of the base plate one 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com