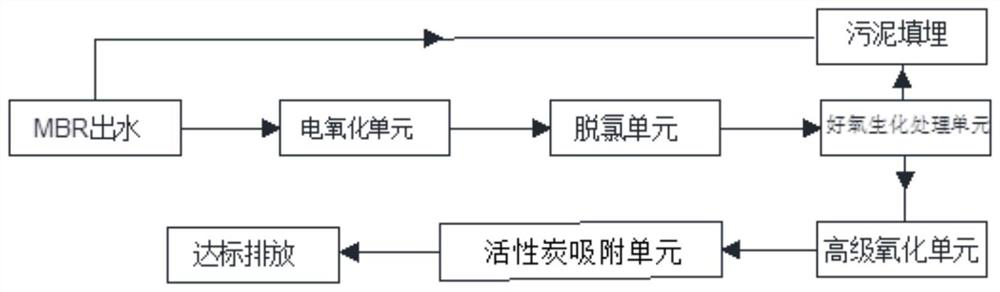

A method and system for treating mbr effluent of landfill leachate

A technology for landfill leachate and effluent treatment, which is applied in infiltration/dialysis water/sewage treatment, polluted groundwater/leachate treatment, water/sewage treatment, etc., and can solve technical problems such as membrane dope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

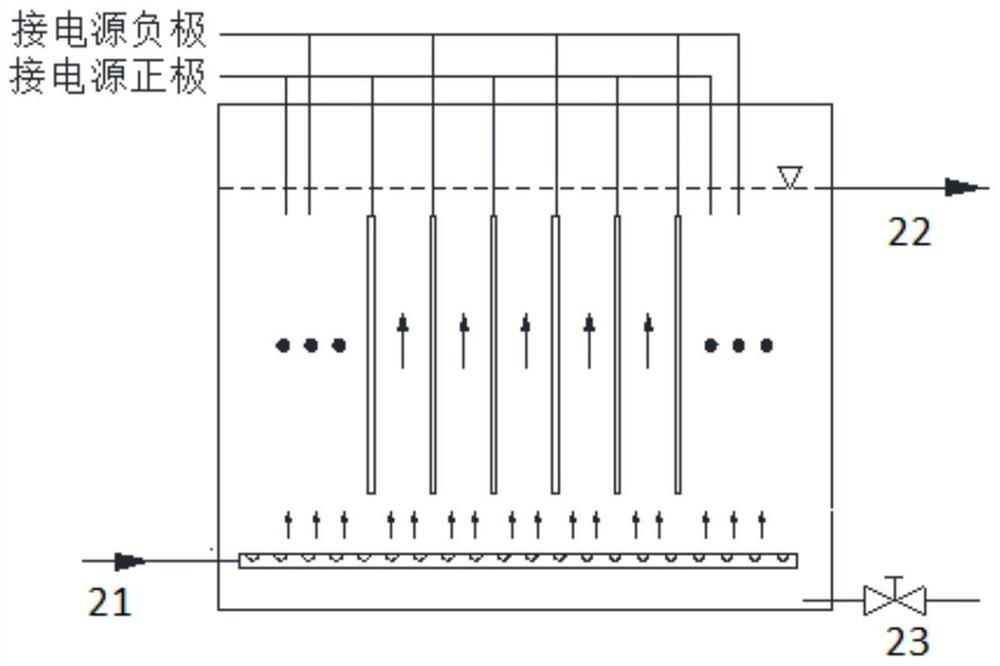

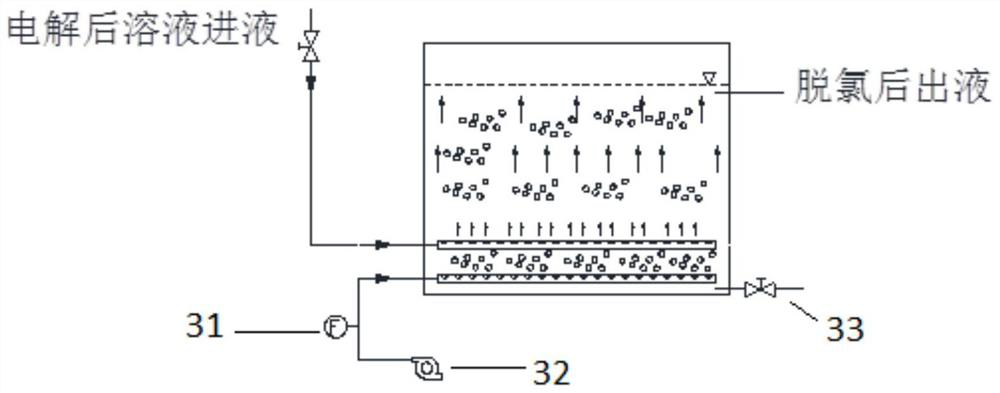

[0056] Embodiment 1: Adopt the method of the present invention to treat the MBR effluent of a landfill leachate treatment plant, COD (chemical oxygen demand)=800~900mg / L, TDS (total dissolved solids)=6000~8000mg / L, NH 3 -N=150~200mg / L, the waste water passes through the electro-oxidation unit, and the current density is controlled at 200~300A / m 2 , the control voltage is 4~6V, after electrolysis, COD in the landfill leachate MBR effluent = 500~600mg / L, TDS=6000~8000mg / L, NH 3 -N=20~50mg / L, [·Cl]≈300mg / L in the landfill leachate MBR effluent. After acid adjustment and aeration by the dechlorination unit, the [·Cl] in the effluent of the landfill leachate MBR = 0 mg / L; the waste water after dechlorination enters the aerobic biochemical treatment unit to reduce the COD in the effluent of the landfill leachate MBR to 330~ 370mg / L, NH 3 -N=10~20mg / L; the biochemical effluent is further treated by electro-oxidation, and the current density is 100A / m 2 , the tank voltage is 3.5~4....

Embodiment 2

[0057] Embodiment 2: Adopt the method of the present invention to treat the MBR effluent of a certain refuse landfill, COD=750~850mg / L, TDS=10000~15000mg / L, NH 3 -N=150~200mg / L, the waste water passes through the electro-oxidation unit, and the electrolysis current density is controlled to be 150~250A / m 2 , the operating voltage of the electrolyzer is 3.5-5.5V. After the electrolysis operation is completed, the COD in the landfill leachate MBR effluent = 500-600mg / L, TDS = 10000-15000mg / L, NH 3 -N=20~50mg / L, [·Cl]≈400mg / L in the landfill leachate MBR effluent. After acid adjustment and aeration, a large amount of active chlorine in the landfill leachate MBR effluent is removed, and the final rate is 0.5kg / m 3 Sodium sulfite is added to make the landfill leachate MBR effluent [·Cl]=0mg / L. After dechlorination, the landfill leachate MBR effluent enters the MBR aerobic biochemical treatment system for a residence time of 4 to 24 hours to remove biochemical organic matter in the...

Embodiment 3

[0058] Embodiment 3: Using the method of the present invention to treat MBR effluent from a waste-to-energy plant, COD=920~1100mg / L, TDS=13000~18000mg / L, NH in the waste water 3 -N=300~400mg / L, the waste water passes through the electro-oxidation unit, and the electrolytic current density is adjusted to 300~450A / m 2 , control the tank voltage at 4.5-6.0V, after the electrolysis is completed, COD in the landfill leachate MBR effluent = 550-650mg / L, NH 3 -N=20~50mg / L, [·Cl]≈350mg / L in the landfill leachate MBR effluent. A large amount of active chlorine in the waste water is removed through acid adjustment and aeration, and then a small amount of sodium sulfite is added to make the [·Cl] in the landfill leachate MBR effluent = 0 mg / L. The deactivated chlorine landfill leachate MBR effluent enters the MBR treatment system of the aerobic biochemical unit, and the residence time is 8 to 24 hours to remove biochemical organic matter in the landfill leachate MBR effluent treated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com