Method for extracting oil vapor from gases of dry distillation furnace

A dry distillation furnace and oil vapor technology, which is applied in the field of oil vapor extraction, can solve the problems of high energy consumption and large processing capacity, and achieve the effects of simplifying the processing process, reducing operating costs, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

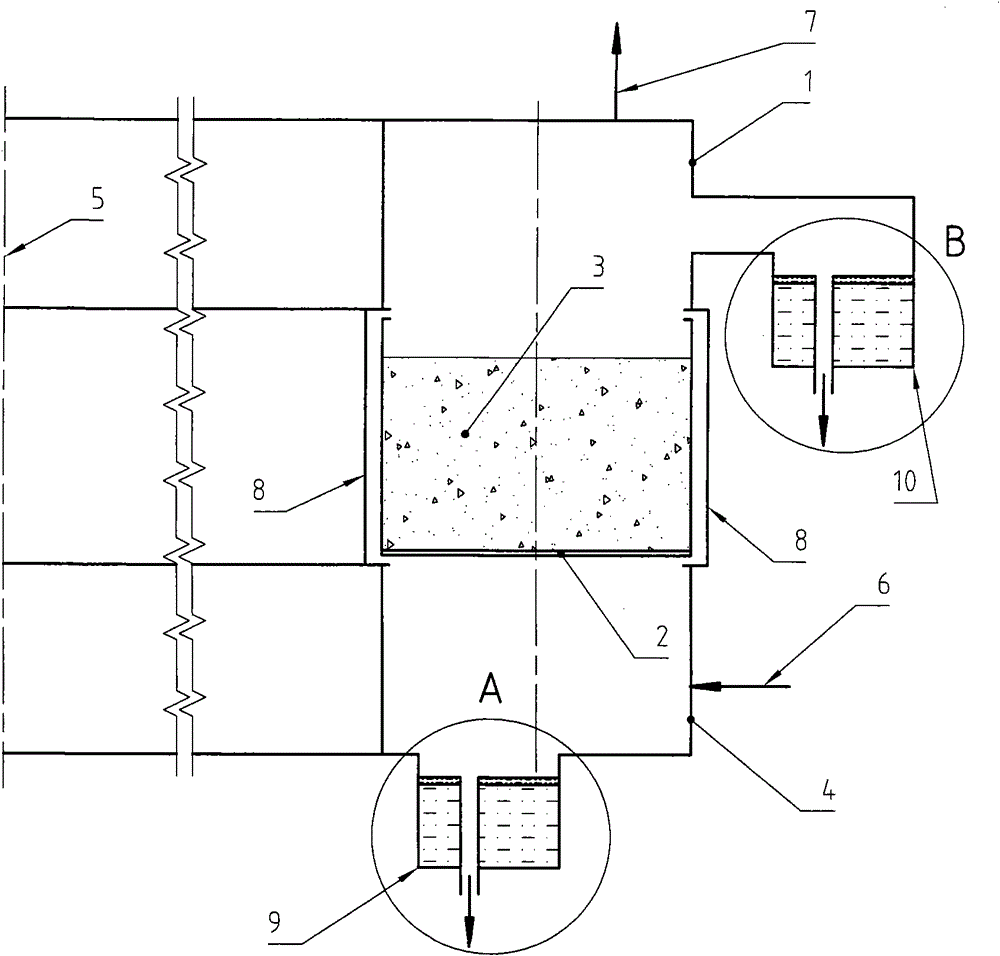

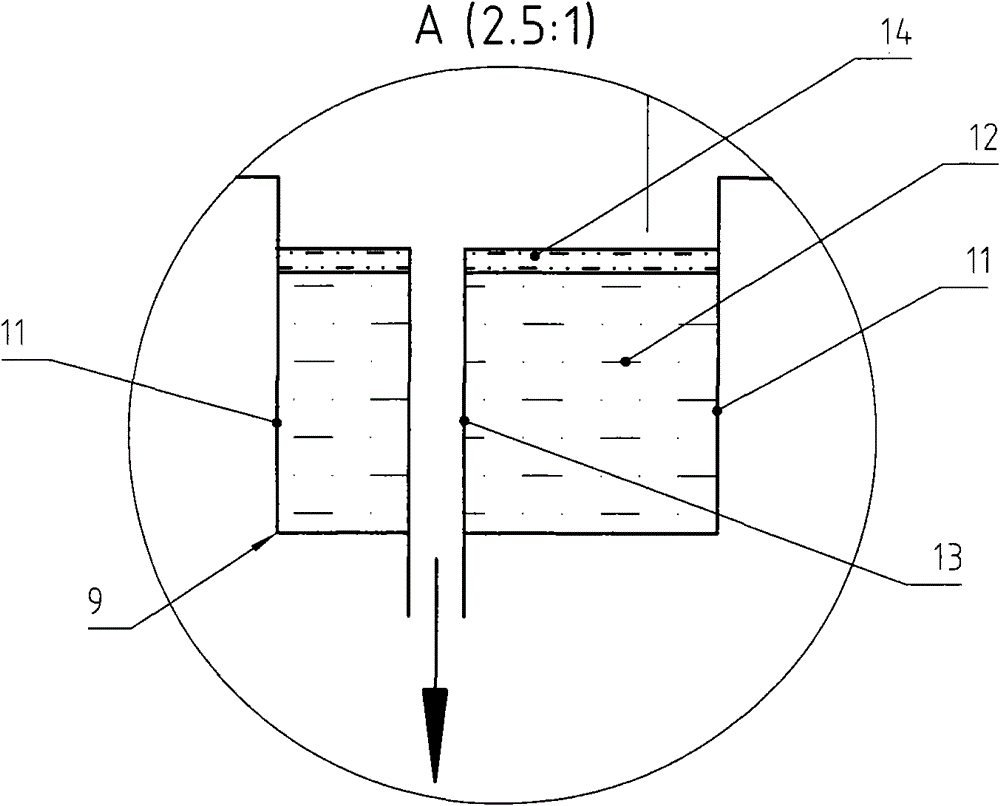

[0033] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 shown.

[0034] figure 1 What is shown is a schematic layout diagram of the general structure of an annular movable grate retort for extracting shale oil and gas from oil shale. Wherein, 1 is the upper cover of this dry distillation furnace. 2 is the moving grate of this carbonization furnace, and this moving grate rotates around center line 5. 3 is the oil shale laid on the movable grate 2. 4 is the lower cover of this dry distillation furnace. The heat-carrying gas or furnace gas enters through the intake pipe 6 , passes through the shale oil layer and is discharged through the exhaust pipe 7 . Its sealing task is finished by closing casing 8.

[0035] In this embodiment, oil vapor absorption tanks 9 and 10 are provided, which are all directly connected to the dry distillation furnace, and these tanks can also be arranged in multiple points. Since their functions are interlinked, only the absor...

Embodiment 2

[0045] Example 2, such as Figure 5 , Image 6 shown.

[0046] Figure 5 What is shown is also a schematic layout diagram of the general structure of an annular movable grate retort furnace for extracting shale oil and gas from oil shale, except that its sealing device adopts a liquid sealing device, and the rest are the same as figure 1 situation is roughly the same. Wherein, 1 is the upper cover of this dry distillation furnace. 2 is the moving grate of this carbonization furnace, and this moving grate rotates around center line 5. 3 is the oil shale laid on the movable grate 2. 4 is the lower cover of this dry distillation furnace. The heat-carrying gas or furnace gas enters through the intake pipe 6, passes through the shale oil layer and is discharged through the exhaust pipe 7, and its sealing task is completed by the liquid sealing device. In this annular moving grate type carbonization furnace, a total of 4 groups of liquid seal devices are used. Shown in Part...

Embodiment 3

[0050] Example 3, such as Figure 7 , Figure 8 shown.

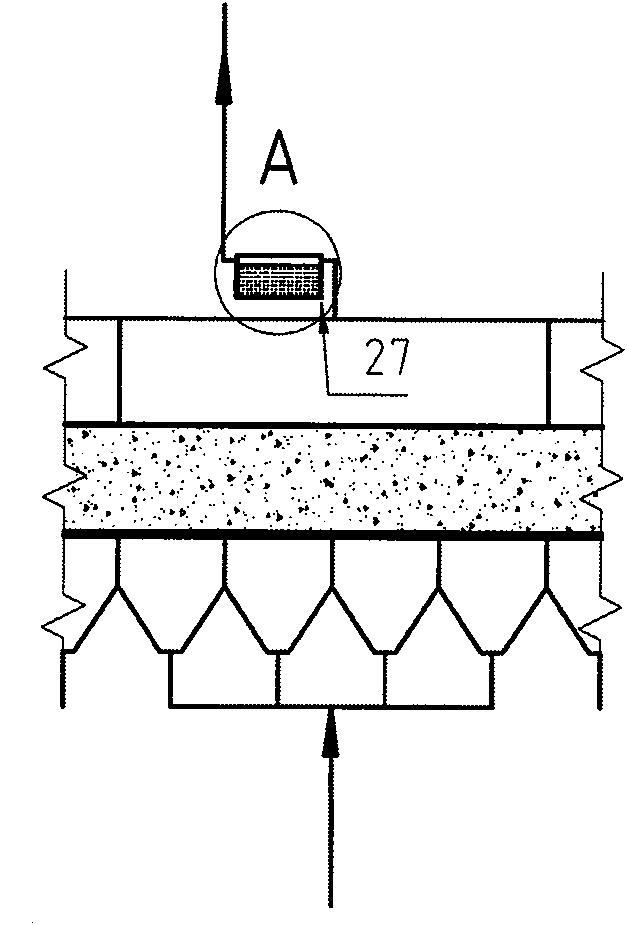

[0051] Figure 7 Shown is a part of the process layout of a dynamic grate retort for extracting shale oil and gas from oil shale; Figure 8 yes Figure 7 Enlarged view of middle A. Figure 7 , Figure 8 Commonly used in this embodiment.

[0052] The purpose of listing this embodiment is to demonstrate the situation that the oil vapor absorbing tank 27 is arranged as close as possible to the furnace gas outlet of the retort furnace. from Figure 7 , Figure 8 It can also be seen from the figure that there is a process of passing the surface of the absorbing liquid during the output of the furnace gas. At this time, part of the oil vapor in the furnace gas can be captured, thereby reducing the concentration of oil vapor in the furnace gas to reduce Or avoid the problem of oil hanging in the furnace gas during the transportation process. As for other details of the oil vapor absorption tank 27, please refer to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com