A method and system for advanced treatment of mbr effluent of landfill leachate

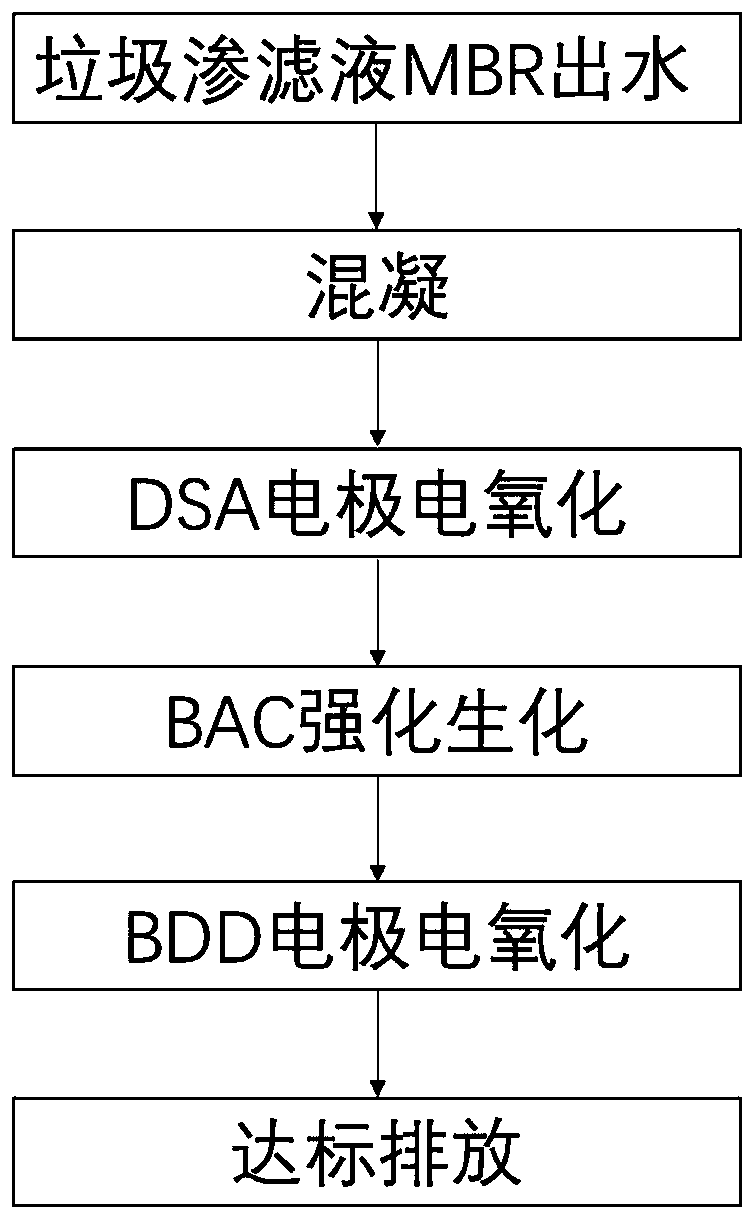

A landfill leachate and advanced treatment technology, applied in the direction of contaminated groundwater/leachate treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high heavy metal content, surface water and groundwater pollution , pollute the surrounding environment and other problems, achieve good COD degradation and denitrification effects, overcome the difficult treatment of membrane dope, and have good promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] COD (chemical oxygen demand) is 1000mg / L, TN (total nitrogen content) = 65mg / L landfill leachate MBR effluent advanced treatment method is as follows:

[0045] Step 1: Coagulation, take the landfill leachate MBR effluent and adjust to pH = 6, add 500mg / L polyferric sulfate to coagulate and precipitate, filter and then adjust the pH to 9, filter after standing to precipitate, so as to further remove residual ferric iron. The COD of the treated effluent is 600mg / L, the content of ammonia nitrogen is 15mg / L, and the content of total nitrogen is 55mg / L.

[0046] Step 2: DSA electrode electrooxidation, take the water from step 1 and place it in the electrolysis device. The maximum power of the constant current stabilized voltage supply is 75W, the current is 0-5A, the voltage is 0-15V, and the volume of the electrolytic tank is 1L. The cathode electrode plate is a DSA electrode plate, the anode electrode plate is a DSA electrode, and the effective area of the electrode pl...

Embodiment 2

[0050] The advanced treatment method of MBR effluent of landfill leachate with COD of 1000mg / L and TN=65mg / L is as follows:

[0051] Step 1: Coagulation, take the landfill leachate MBR effluent and adjust to pH = 3, add 2000mg / L polyferric sulfate to coagulate and precipitate, filter and then adjust the pH to 9, filter after standing to precipitate, so as to further remove residual ferric iron. The COD of the treated effluent is 450mg / L, the content of ammonia nitrogen is 14mg / L, and the content of total nitrogen is 42mg / L;

[0052] Step 2: DSA electrode electrooxidation, take the water from step 1 and place it in the electrolysis device. The maximum power of the constant current stabilized voltage supply is 75W, the current is 0-5A, the voltage is 0-15V, and the volume of the electrolytic tank is 1L. The cathode electrode plate is a stainless steel electrode plate, the anode electrode plate is a DSA electrode, and the effective area of the electrode plate is 96cm 2 ; The ...

Embodiment 3

[0056] The advanced treatment method of MBR effluent of landfill leachate with COD of 1300mg / L and TN=115mg / L is as follows:

[0057] Step 1: Coagulation, take the landfill leachate MBR effluent and adjust to pH = 3, add 1500mg / L polyferric sulfate to coagulate and precipitate, filter and then adjust the pH to 9, and filter after standing to precipitate to further remove residual ferric iron. The COD of the treated effluent is 700mg / L, the content of ammonia nitrogen is 30mg / L, and the content of total nitrogen is 105mg / L;

[0058] Step 2: DSA electrode electrooxidation, take the water from step 1 and place it in the electrolysis device. The maximum power of the constant current stabilized voltage supply is 75W, the current is 0-5A, the voltage is 0-15V, and the volume of the electrolytic tank is 1L. The cathode electrode plate is a DSA electrode plate, the anode electrode plate is a DSA electrode, and the effective area of the electrode plate is 56cm 2 ; The current is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com