New compound bis-(4-aminophenyl) phenyl phosphonate and synthesis method thereof

A technology of phenylphosphonate and aminophenyl, which is applied in the field of compound di-phenylphosphonate and its synthesis, can solve problems such as easy fire and restriction, and achieves that it is not easy to migrate and exude, and has little impact on performance. , the effect of permanent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

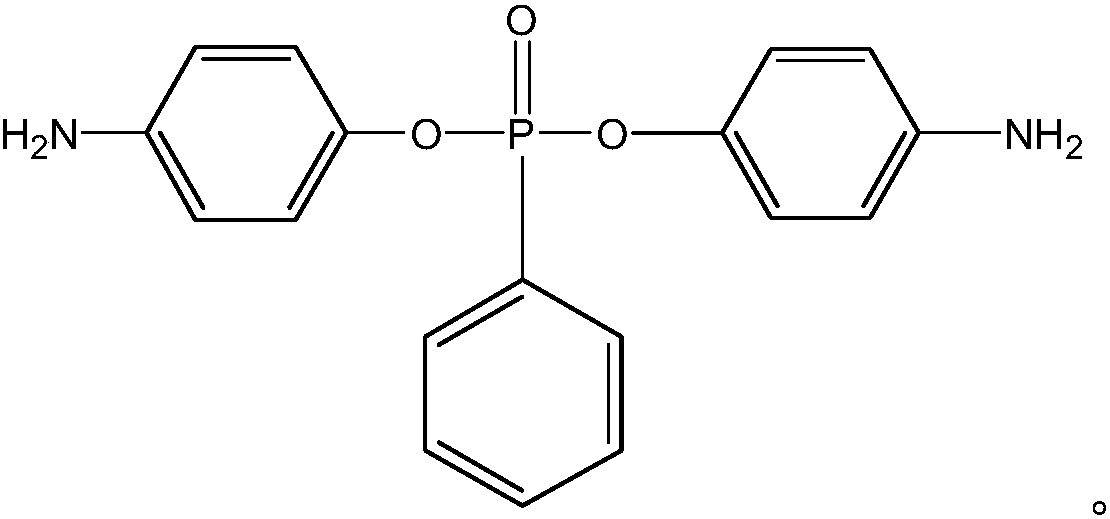

[0030] A kind of compound bis-(4-aminophenyl) phenyl phosphonate, its molecular structural formula is as follows:

[0031]

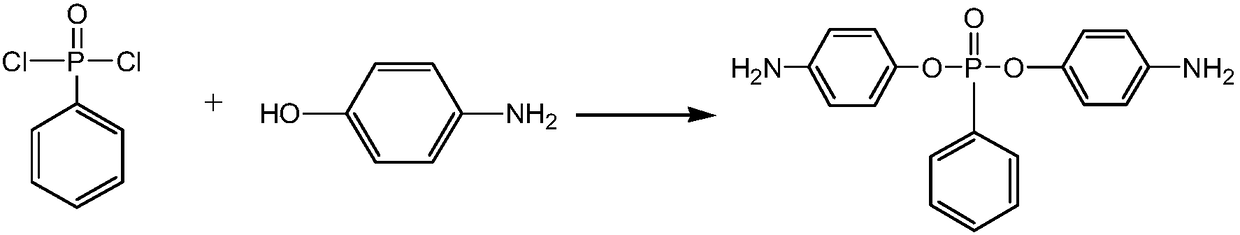

[0032] Compound bis-(4-aminophenyl) phenyl phosphonate synthetic method, the steps are as follows:

[0033] 1) Weigh p-aminophenol (2.18g 0.02mol) and phenylphosphonic dichloride (1.95g0.01mol) at a molar ratio of 2:1, and weigh Cu according to the amount of catalyst added as 1wt% of the p-aminophenol mass 2 Cl 2 (0.02g).

[0034] 2) Under an inert gas atmosphere, add a dropping funnel, a stirrer, anhydrous CaCl 2 Add p-aminophenol, 3ml triethylamine and 20ml tetrahydrofuran to the condensing reflux device of the protective tube, and cool to 0°C in an ice-water bath. Then add Cu 2 Cl 2 , Dissolve phenylphosphonic dichloride in 10ml tetrahydrofuran, add dropwise within 1.5h, and react at 30°C for 24h. The final product was obtained after filtration, precipitation and recrystallization.

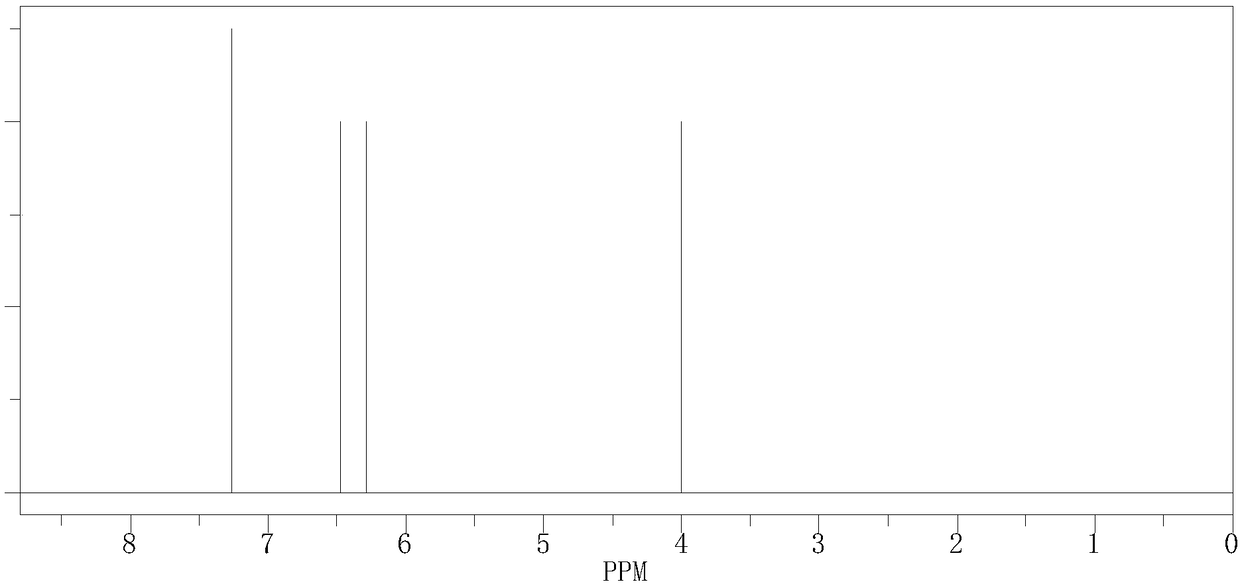

[0035] figure 1 As a new curing agent bis-(4-aminophenyl)...

Embodiment 2

[0039] Compound two-(4-aminophenyl) phenyl phosphonate, its synthetic method is as follows:

[0040] 1) Weigh p-aminophenol (2.18g 0.02mol) and phenylphosphonic dichloride (1.95g0.01mol) at a molar ratio of 2:1, and weigh Cu according to the amount of catalyst added as 1.5wt% of the p-aminophenol mass 2 Cl 2 (0.03g).

[0041] 2) Under an inert gas atmosphere, add a dropping funnel, a stirrer, anhydrous CaCl 2 Add p-aminophenol, 3ml triethylamine and 20ml tetrahydrofuran to the condensing reflux device of the protective tube, and cool to 0°C in an ice-water bath. Then add Cu 2 Cl 2 , Dissolve phenylphosphonic dichloride in 10ml tetrahydrofuran, add dropwise within 1h, and react at 30°C for 24h. The final product was obtained after filtration, precipitation and recrystallization.

Embodiment 3

[0043] Compound, its synthetic method is as follows:

[0044] 1) Weigh p-aminophenol (2.18g 0.02mol) and phenylphosphonic dichloride (1.95g0.01mol) at a molar ratio of 2:1, and weigh Cu according to the amount of catalyst added as 2wt% of the p-aminophenol mass 2 Cl 2 (0.04g).

[0045] 2) Under an inert gas atmosphere, add a dropping funnel, a stirrer, anhydrous CaCl 2 Add p-aminophenol, 3ml triethylamine and 20ml tetrahydrofuran to the condensing reflux device of the protective tube, and cool to 0°C in an ice-water bath. Then add Cu 2 Cl 2, Dissolve phenylphosphonic dichloride in 10ml tetrahydrofuran, add dropwise within 2h, and react at 30°C for 24h. The final product was obtained after filtration, precipitation and recrystallization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com