High-temperature-resistant plugging agent and preparation method of same

A plugging agent and high-temperature-resistant technology, which is applied in the field of oil drilling, can solve the problems of difficult size control, easy knotting, unfavorable underground construction, etc., and achieve the effect of loose use environment, low economic cost and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

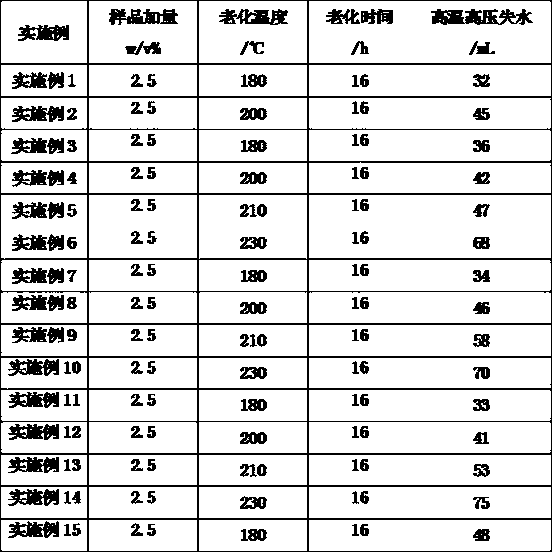

Examples

Embodiment 1

[0027] The 50 micron walnut hull powder 10%, 35 micron chaff powder 15%, 50 micron cotton seed hull powder 22%, number average molecular weight 1000 hydroxyl-terminated carborane polyester resin 20%, 50 micron asbestos powder 8%, carbon powder 8%, and diphenylmethane diisocyanate 17% are mixed and stirred for 10 minutes under normal temperature and pressure to obtain high temperature resistant plugging agent.

Embodiment 2

[0029] The 37 micron walnut shell powder 12%, 46 micron apricot shell powder 13%, 80 micron coconut shell powder 11%, number average molecular weight of 1100 hydroxyl-terminated carborane polyester resin 23%, 35 micron asbestos powder 12%, 9% carbon powder, 20% diphenylmethane diisocyanate are mixed and stirred for 5 minutes under normal temperature and pressure to obtain high temperature resistant plugging agent.

Embodiment 3

[0031] The 37 micron walnut shell powder 10%, 46 micron apricot shell powder 12%, 60 micron sawn wood surface 20%, number average molecular weight of 1200 hydroxyl-terminated carborane polyester resin 19%, 50 micron asbestos powder 10%, 9% carbon powder, and 20% toluene diisocyanate are mixed and stirred for 8 minutes under normal temperature and pressure to obtain high temperature resistant plugging agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com