Vertical traffic transportation system and method and vertical bridge traffic transportation device

A transportation and vertical technology, applied in the field of transportation, can solve the problems of heavy air pollution, loud noise, and difficulty in on-site assembly, so as to reduce personnel loss and economic loss, reduce power configuration and energy consumption, and reduce maintenance workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

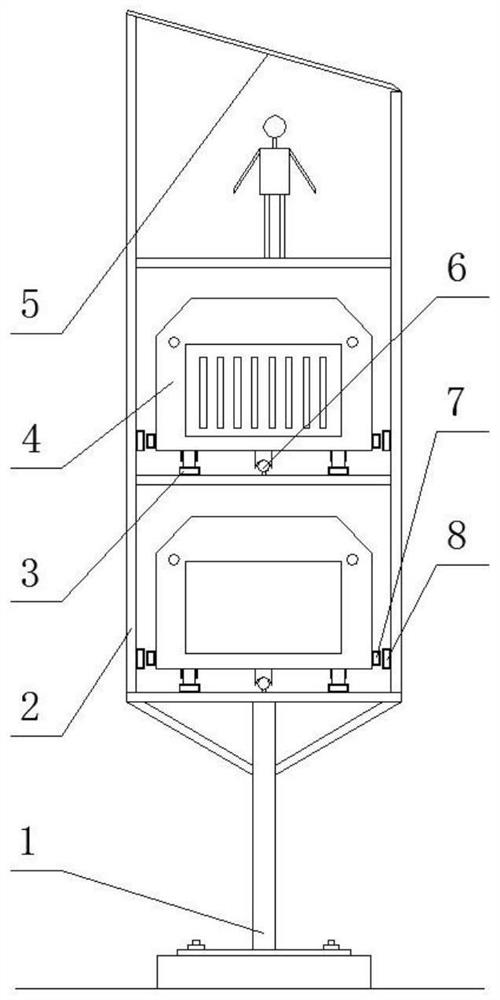

[0106] like figure 1 As shown, a vertical transportation system includes a column 1, a vertical traffic corridor 2, a lane 3 and a vehicle 4. The column 1 is a steel structure or a reinforced concrete structure, and the column 1 is fixed to the reinforcement of the foundation pit through anchor bolts. On the concrete foundation, the vertical traffic corridor 2 is built on the column 1 and erected in the air through the column 1; the interior of the vertical traffic corridor 2 is set up with traffic floors from bottom to top, and the number of traffic floors is determined according to the transportation volume; There is lane 3 in the driving layer. Lane 3 is made of section steel. The section steel includes steel rail, I-beam, H-beam, channel steel, steel pipe, etc. Lane 3 is both a lane and a structural beam of vertical traffic corridor 2. Beams are used as lanes to further simplify the structure of the vertical traffic corridor 2 and reduce its manufacturing cost; photovoltai...

Embodiment 2

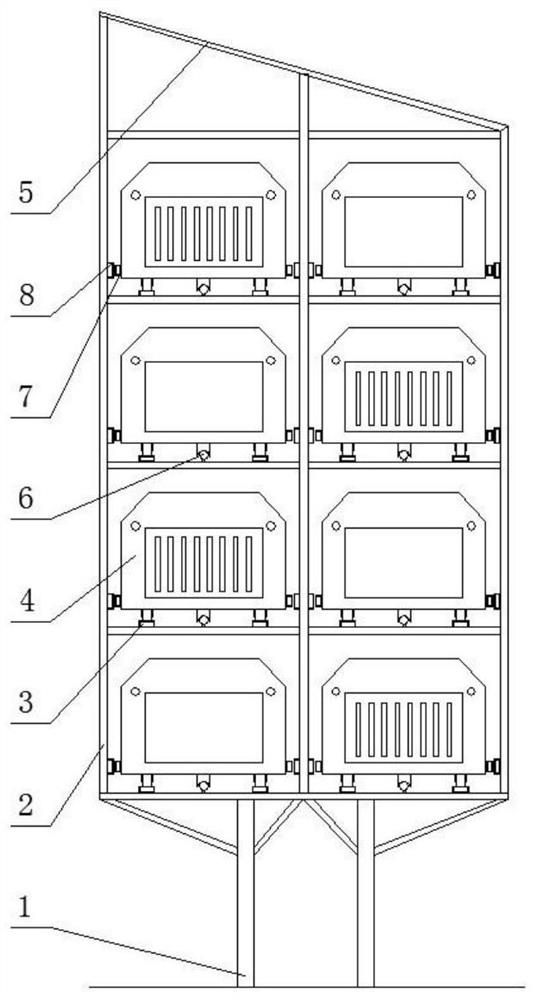

[0117] like figure 2 As shown, a vertical transportation system, including a column 1, a vertical traffic corridor 2, a lane 3 and a vehicle 4, is basically the same as the embodiment 1, except that each column 1 is composed of two foundation piles, Each traffic layer has two-way two-lane 3, and the four-layer traffic layer is equivalent to two-way eight-lane; vehicles 4 are generally self-driving electric vehicles dedicated to vertical traffic corridors 2, including passenger cars, trucks and flatbed vehicles; existing vehicles especially have The electric vehicle with assisted driving function and automatic driving function (L2 or L3 level is sufficient) or the electric vehicle after simple transformation can also drive in the vertical traffic corridor 2. To prevent the vehicle from deviating from lane 3, add a power connection device at the bottom of the vehicle, use electricity and charge online through the conductor rail 6, and the electric vehicle accepts the command an...

Embodiment 3

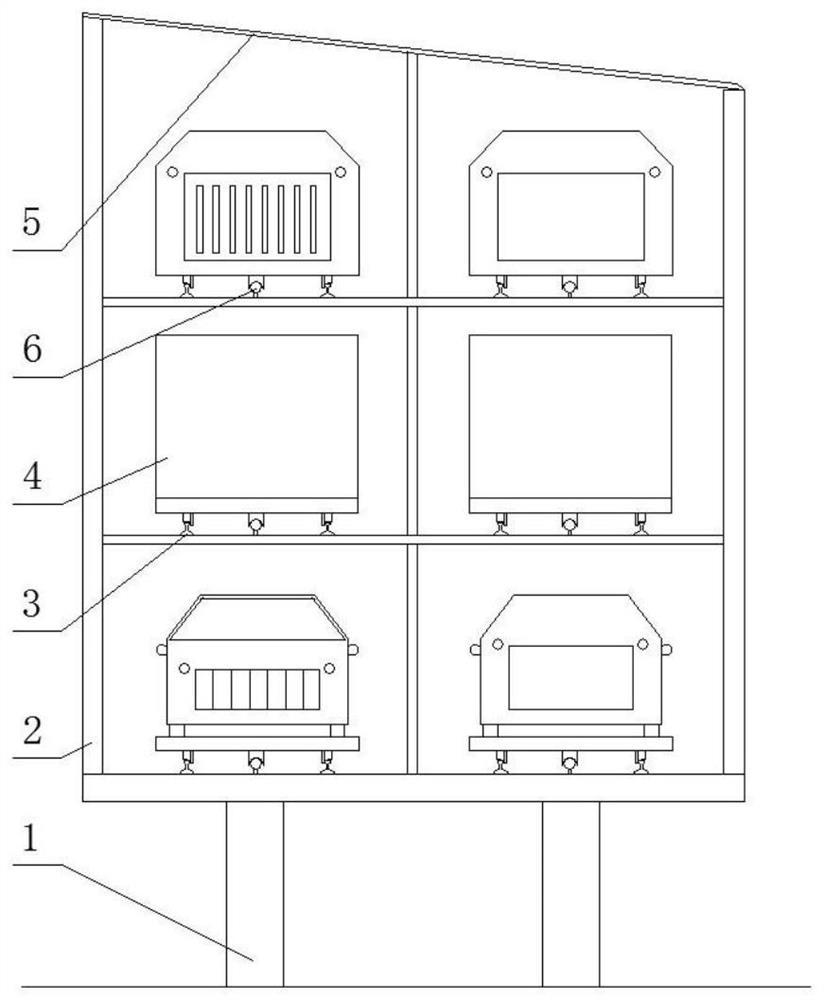

[0119] like image 3 As shown in the figure, a vertical bridge transportation device is suitable for long-strip traffic corridors, especially for the construction of bridges with large spans, such as sea-crossing bridges, etc. The system includes a column 1, a vertical traffic corridor 2, a lane 3 and vehicle 4, the column 1 is the pile foundation used to build the bridge, which is driven into the ground by the piling boat. After the column 1 is installed, the vertical traffic corridor 2 is installed on it, and the vertical traffic corridor 2 can be produced by modularization. , All modules are assembled in the factory and transported to the site directly, which not only has low cost and good quality, but also simple process and short construction time. The vertical traffic corridor 2 can be divided into three layers of traffic layers, the first layer below is the traffic layer of flatbed vehicles, which is used for consignment of existing cars, the second layer is trucks, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com