Device for controlling pouring height of concrete at lower end of framework, and using method thereof

A concrete and frame technology, applied in building construction, building material processing, building type, etc., can solve problems such as difficulty in controlling the elevation of the upper surface of concrete, increasing the strength and stiffness of the root of the frame, and affecting the removal of accumulated water in the frame, etc. To achieve the effect of easy control of depth, extended service life and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

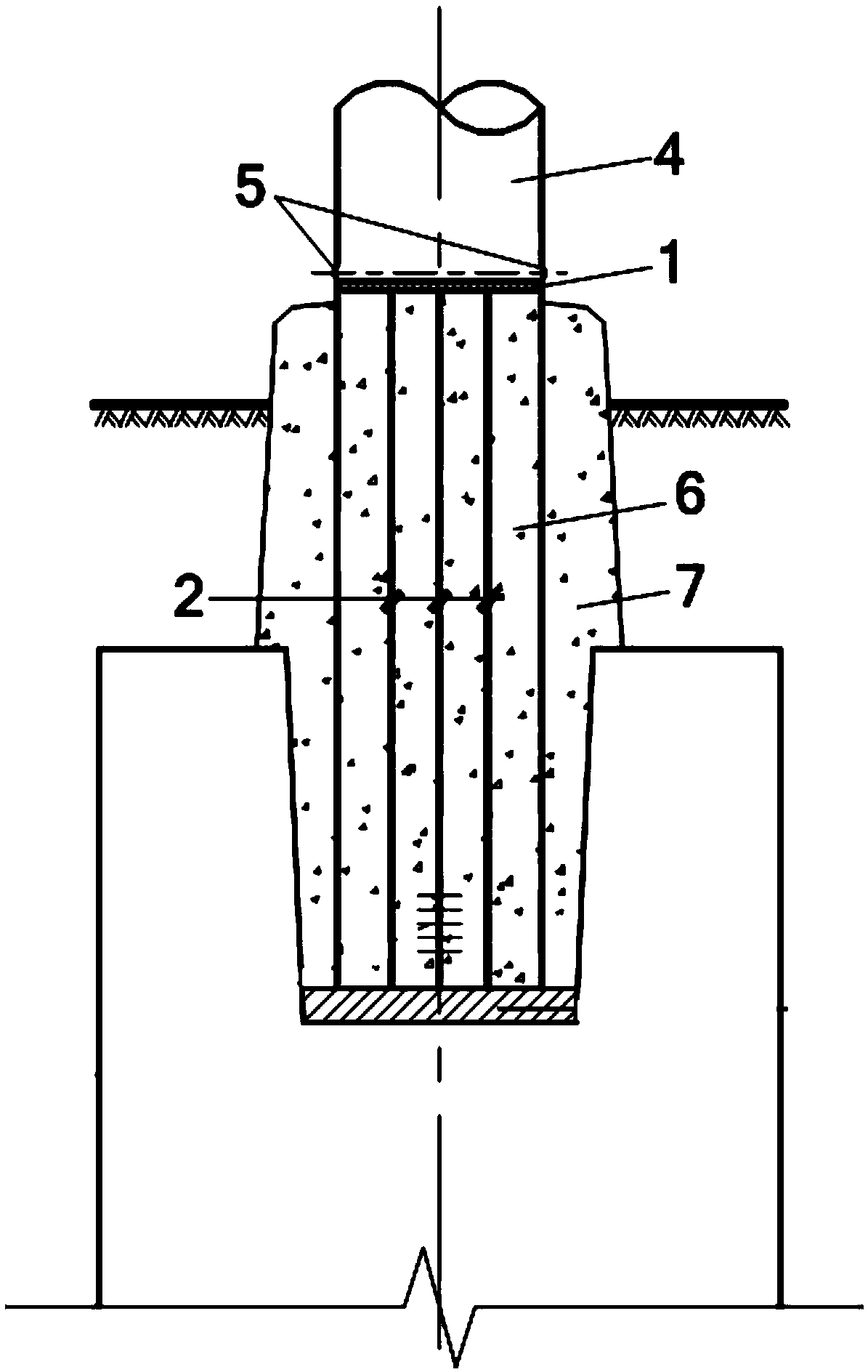

[0023] In order to more clearly illustrate the technical means and creative features of the implementation of the present invention, the present invention will be further elaborated below in conjunction with the accompanying drawings.

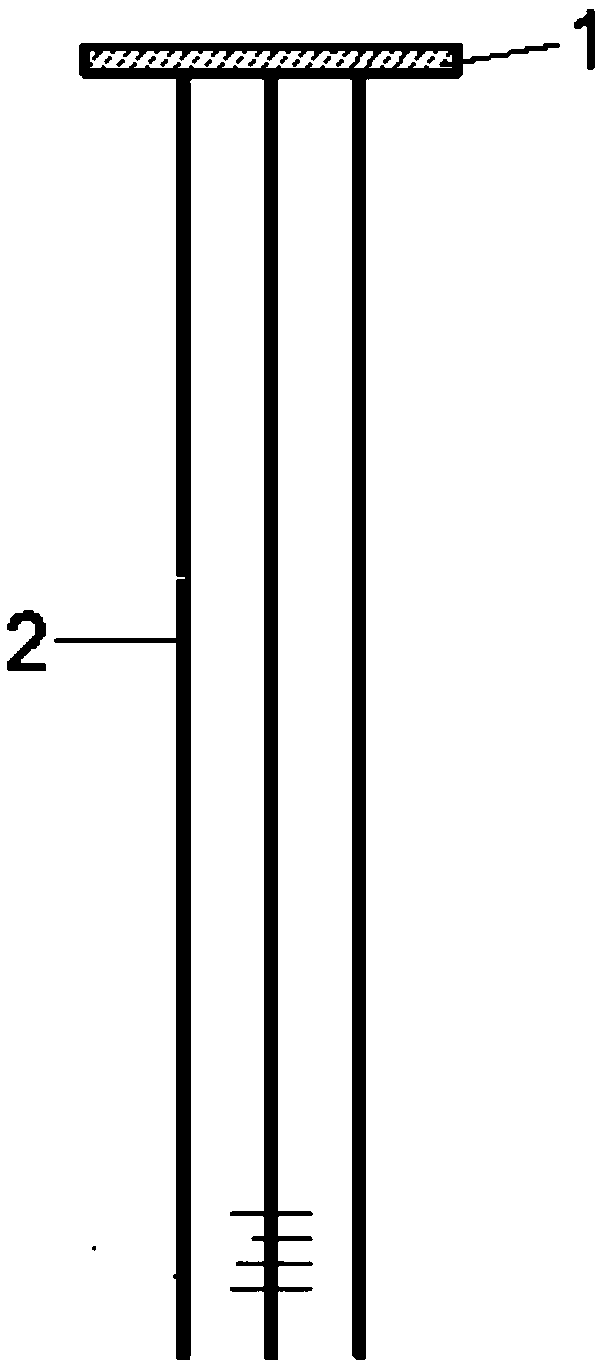

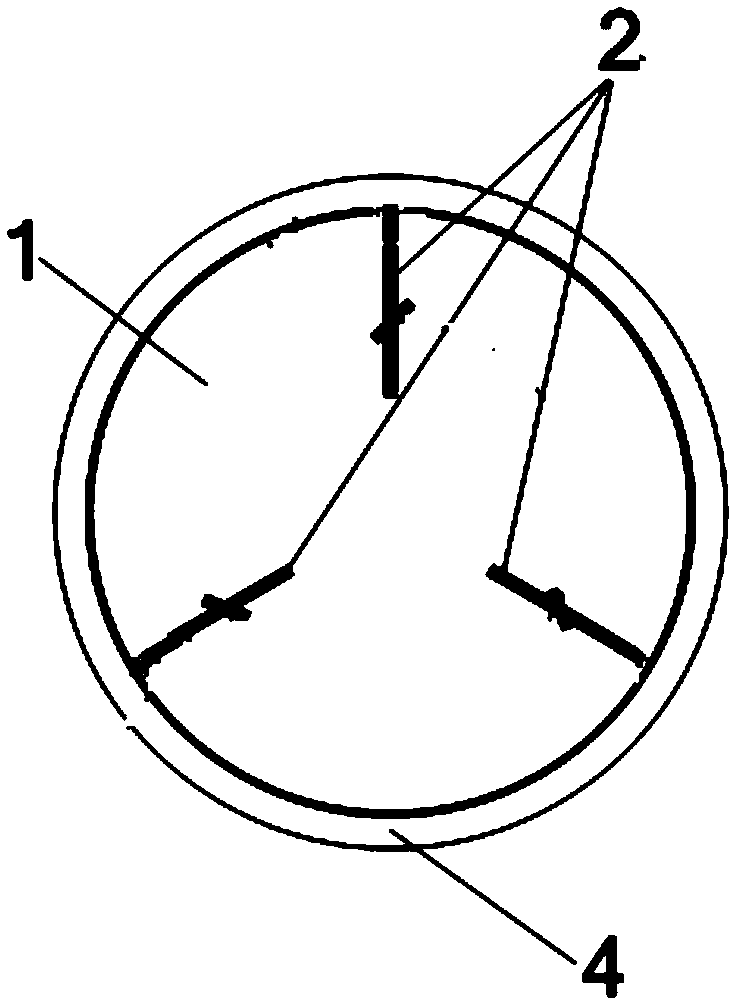

[0024] Such as figure 1 As shown, a device for controlling the pouring height of concrete in the steel pipe at the root of the frame includes a grout plate 1 and a positioning steel bar 2 .

[0025] Wherein, the baffle plate 1 is in the shape of a disk, and its diameter matches the inner diameter of the frame 4. The bottom surface of the baffle plate 1 is vertically and fixedly connected with a plurality of positioning steel bars 2, and the circumference of the multiple positioning steel bars 2 are evenly distributed on the wall of the baffle plate 1. on and at the edge of the baffle 1.

[0026] The length of the positioning stiffener 2 is equal to the distance from the lower end of the frame 4 to the surface elevation.

[0027] The number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com