Vertical movement lamp control main machine and vertical movement lamp group control system

A technology for controlling hosts and moving lights, applied in the direction of use feedback control, lighting and heating equipment, lighting device components, etc., can solve problems such as the inability to achieve multiple changing effects, improve flexibility, reduce wear and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

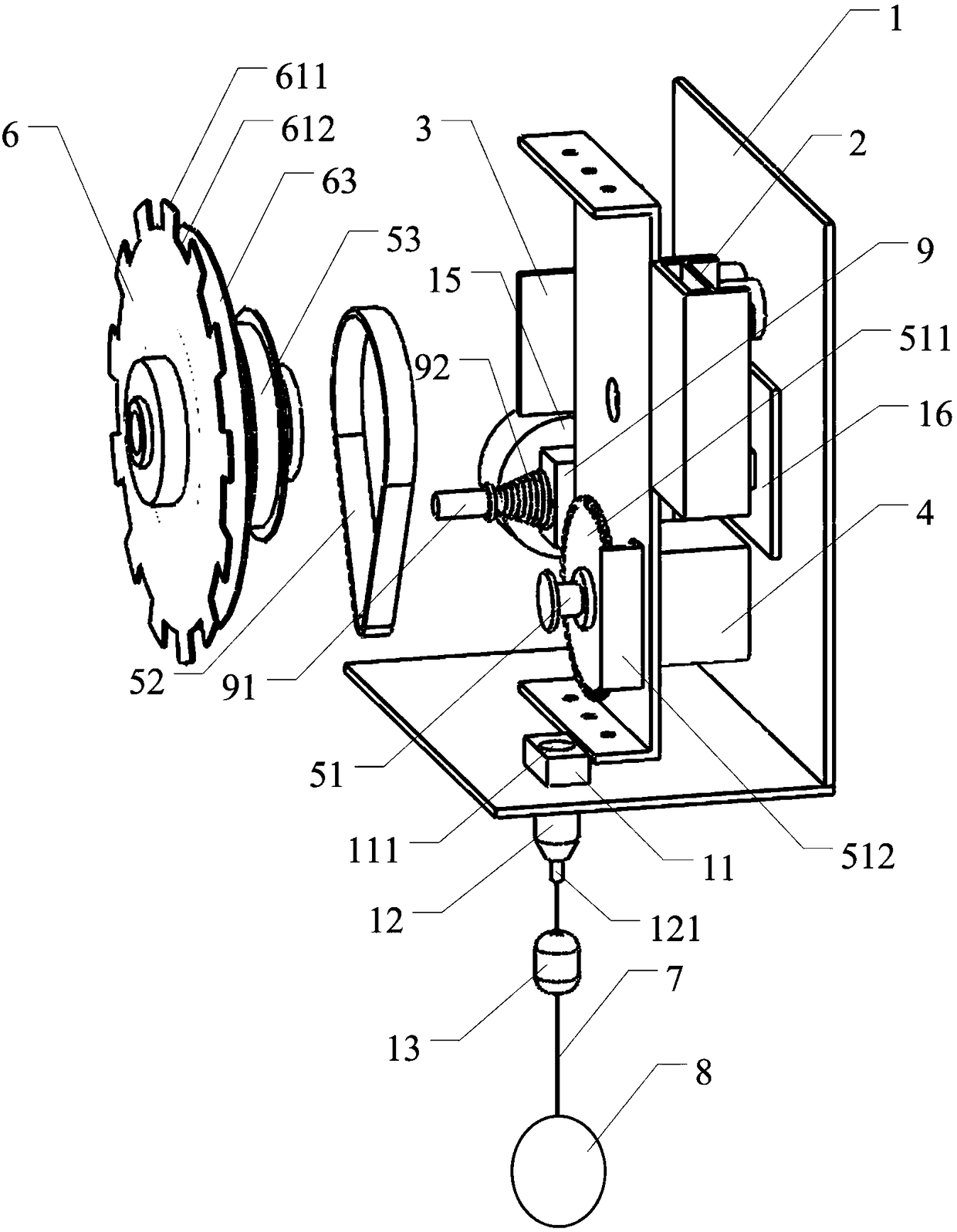

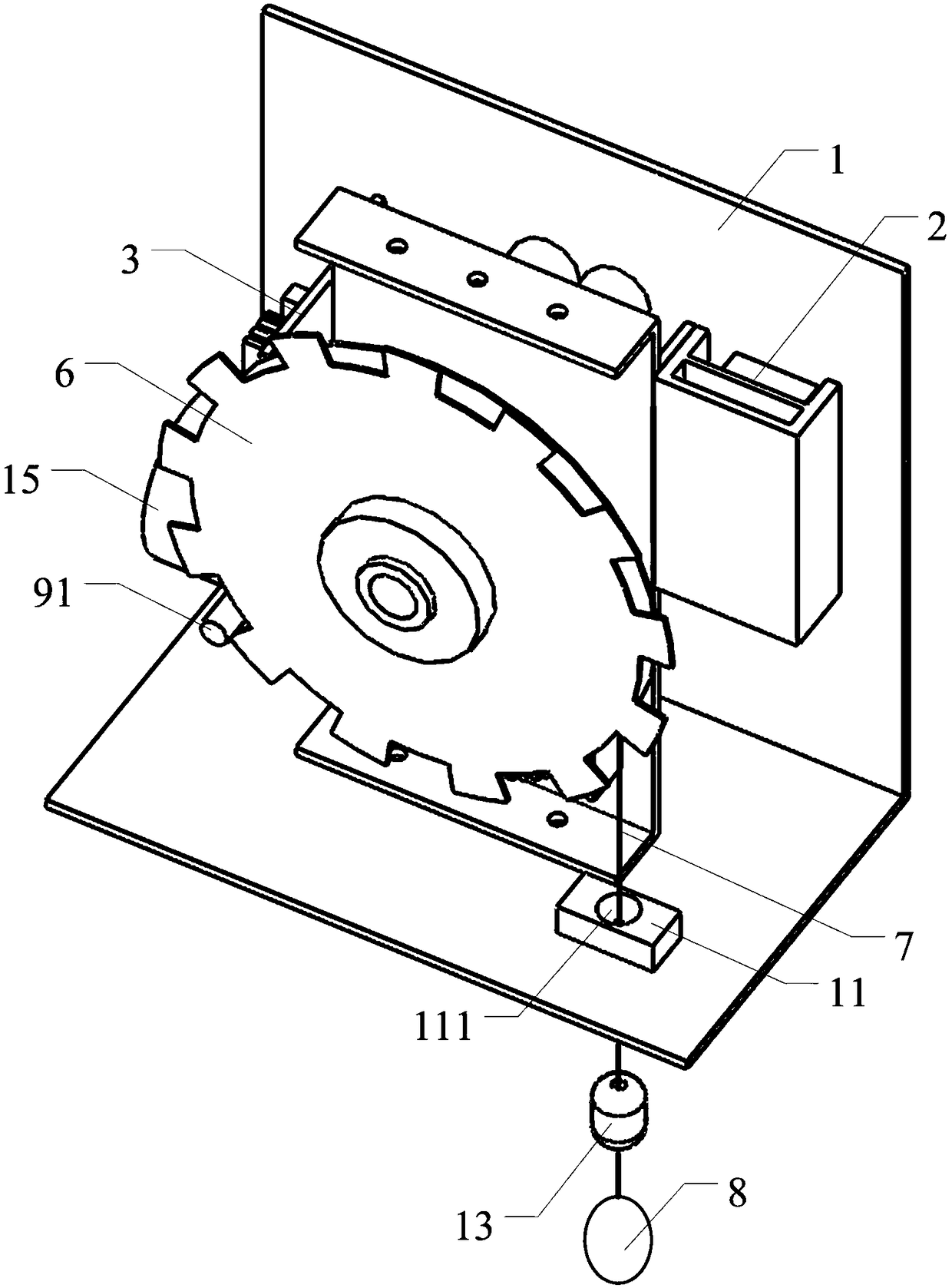

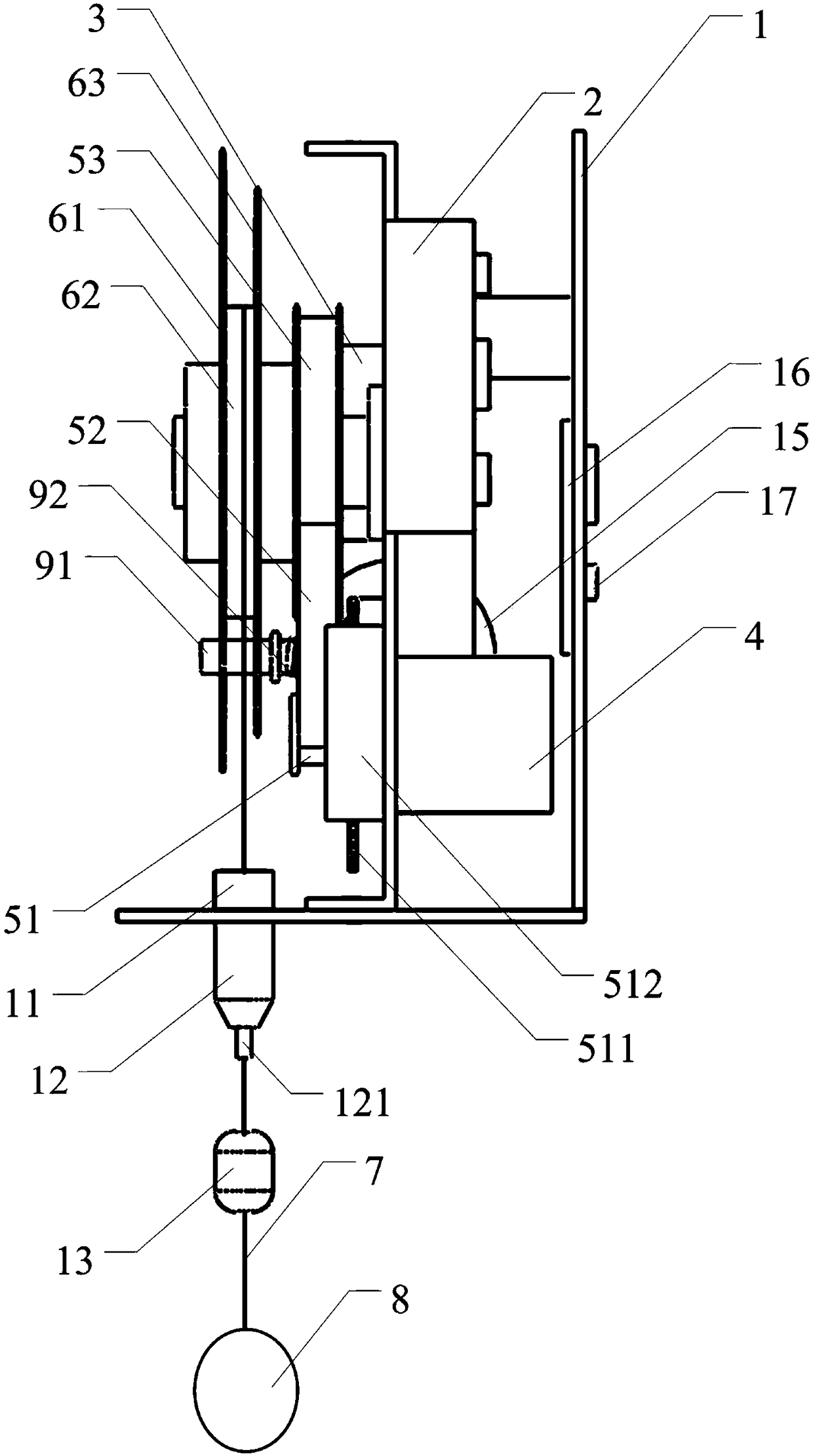

[0028] The following combination Figure 1 to Figure 5 The specific embodiment of the present invention is further elaborated:

[0029] A control host for vertically moving lamps, comprising a chassis 1, a power module 2, a main control module 3 and a motor 4 are arranged inside the chassis 1, the power module 2 provides electric energy for the main control module 3 and the motor 4, and the main control module 3 controls the motor 4 rotation state;

[0030] The rotating shaft of the motor 4 is connected with a small synchronous wheel 51, and the small synchronous wheel 51 is connected with the large synchronous wheel 53 through a synchronous belt 52, so even a motor with a small power can output a large torque, which can drive the lifting of the heavier lamp 8 The large synchronous wheel 53 is coaxially connected with the winding reel 6, one end of the suspension wire 7 is wound on the winding reel 6, and the other end passes through the wire hole provided at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com