Air cooler tube leaking stoppage screwed plug structure

A technology of air coolers and tubes, which is applied in the field of air cooler tube leakage treatment, which can solve the problems of tube leakage, long downtime, and low plugging success rate, and achieve high safety, less downtime, and plugging effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

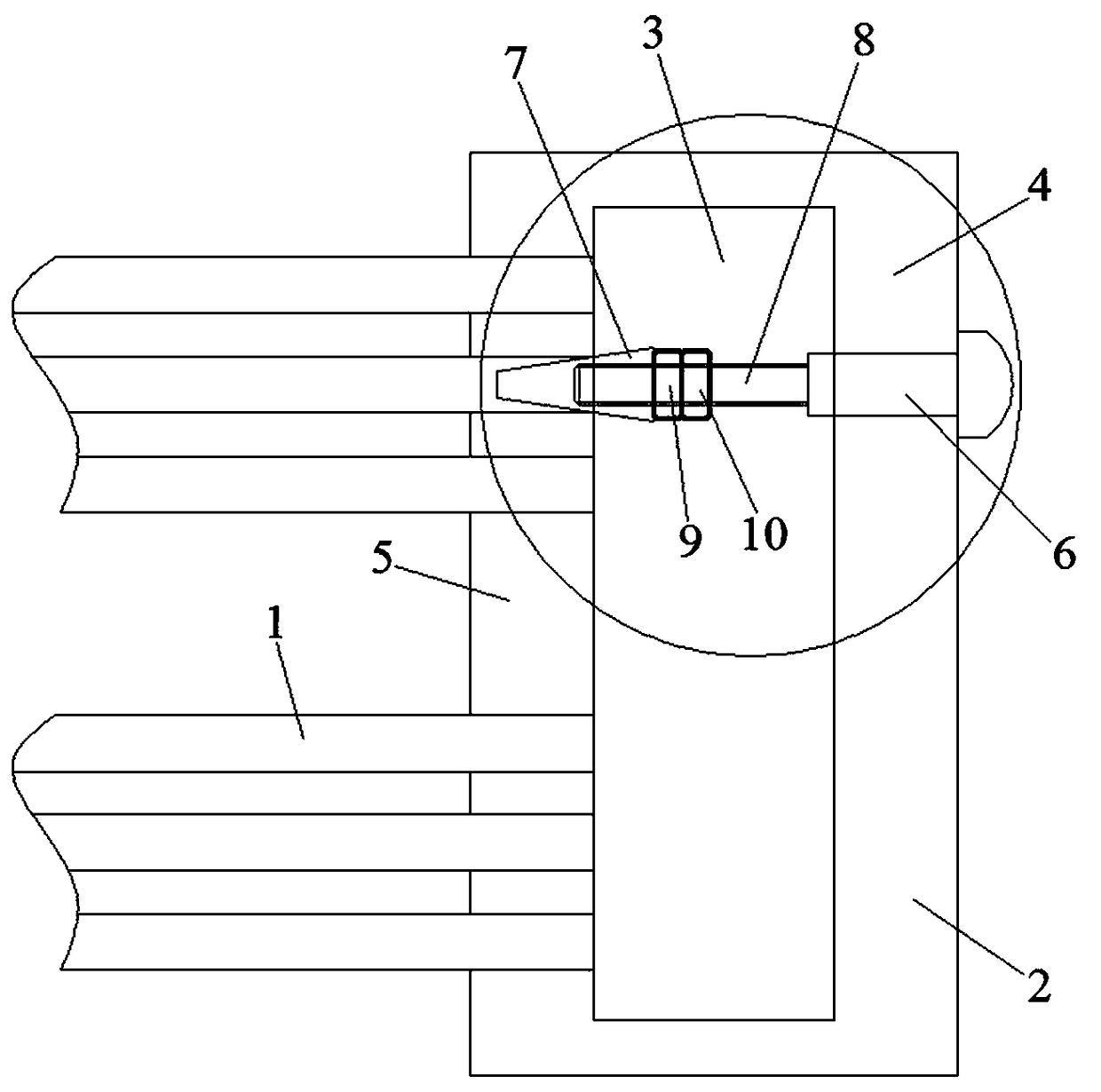

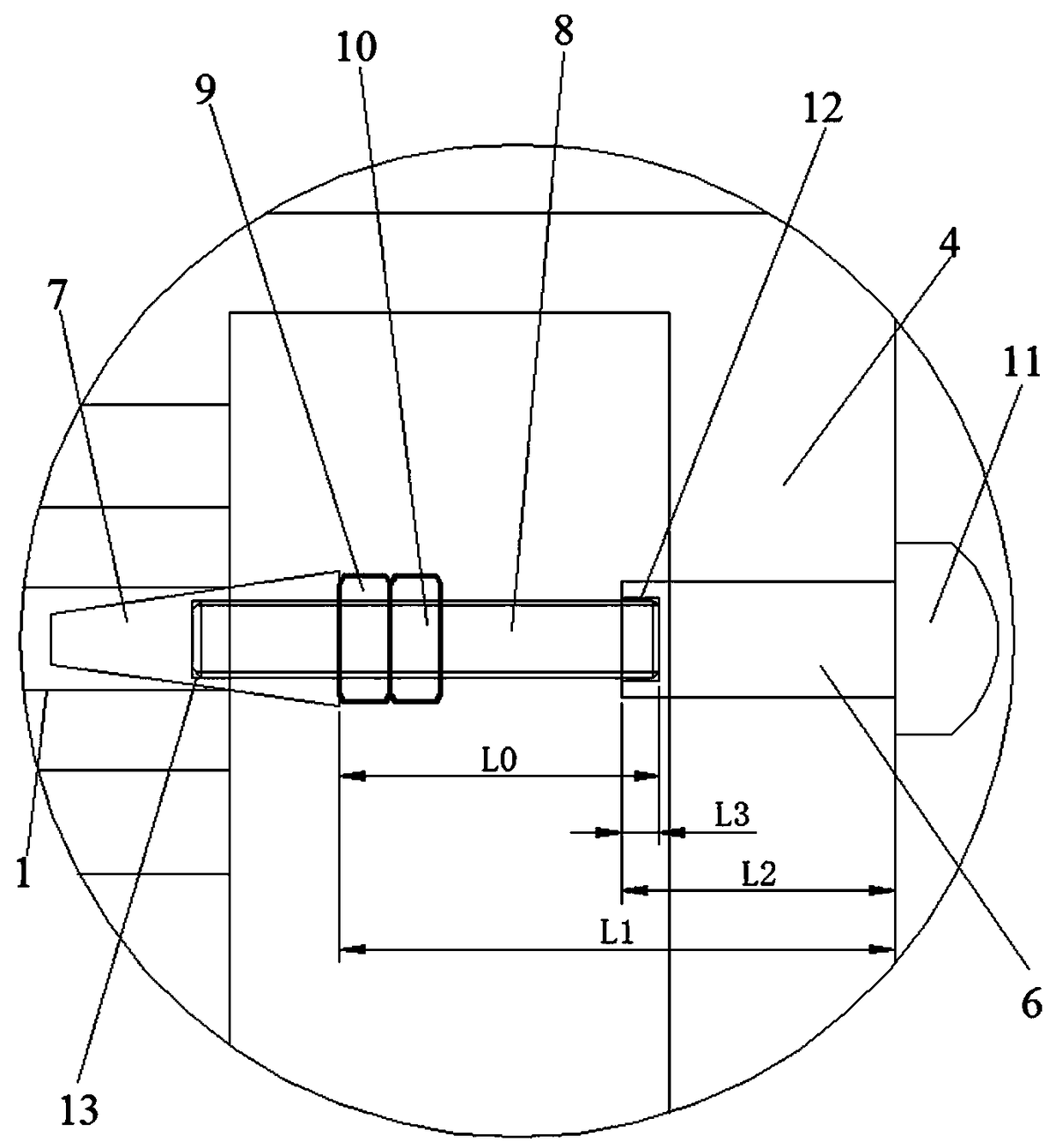

[0015] As shown in the accompanying drawings, an air cooler tube leak plugging and plugging structure includes several air cooler tubes 1 and tube boxes 2 at both ends of the air cooler tube 1, and the tube box 2 includes a rectangular parallelepiped in the middle. The inner cavity 3, the inner tube box inner wall 5 with a certain thickness and the outer tube box outer wall 4, both ends of the air cooler tube 1 are inserted into the inner wall 5 of the tube box 2, and at the end of the leaking air cooler tube 1 A conical hard rubber taper plug 7 is inserted on the top, the taper of the taper plug 7 is 1:5, the diameter of the small end of the taper plug 7 is smaller than the inner diameter of the tube 1 of the air cooler, and the diameter of the big end is larger than the inner diameter of the tube 1 of the air cooler. The tube box plug 6 with a plug cap 11 is screwed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com