Measurement device and method of billet heating temperature uniformity

A billet heating and uniformity technology, applied in the field of steel rolling heating in the metallurgical industry, can solve problems such as poor accuracy of heating temperature uniformity evaluation, and achieve the effect of solving poor accuracy, ensuring accuracy, and accurate billet surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

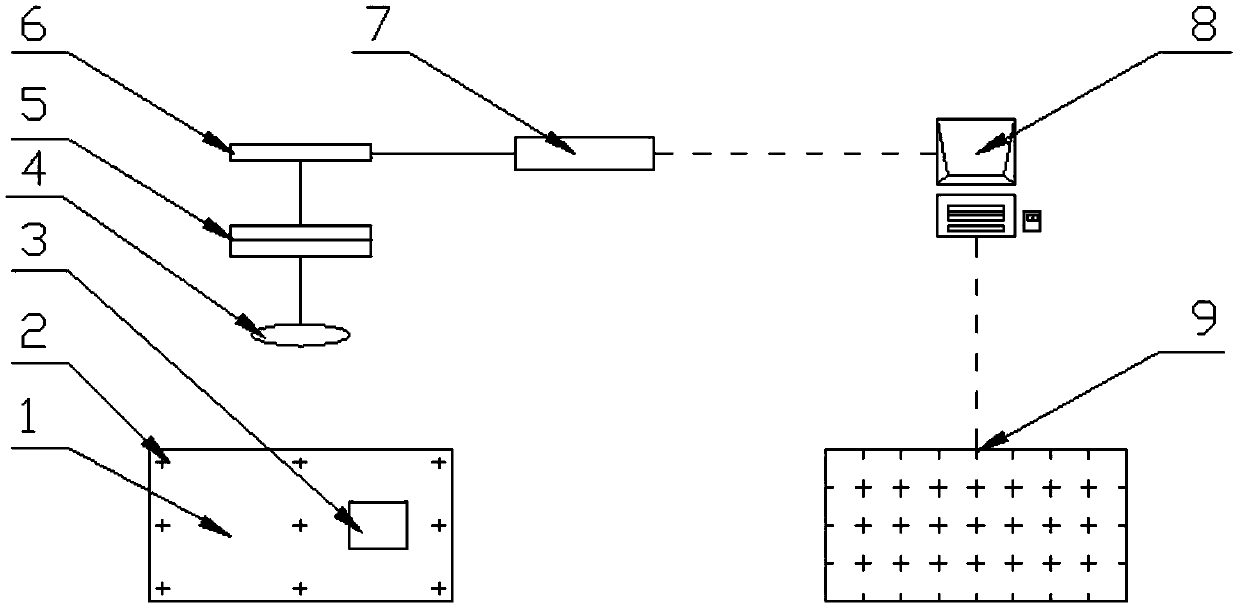

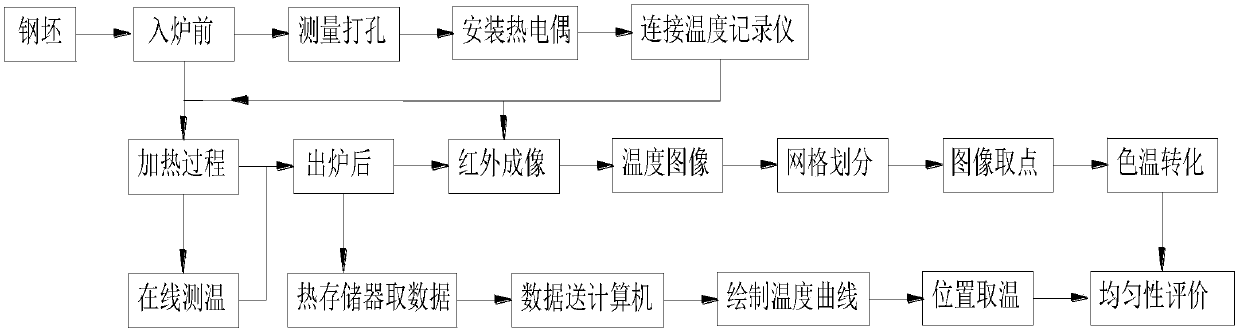

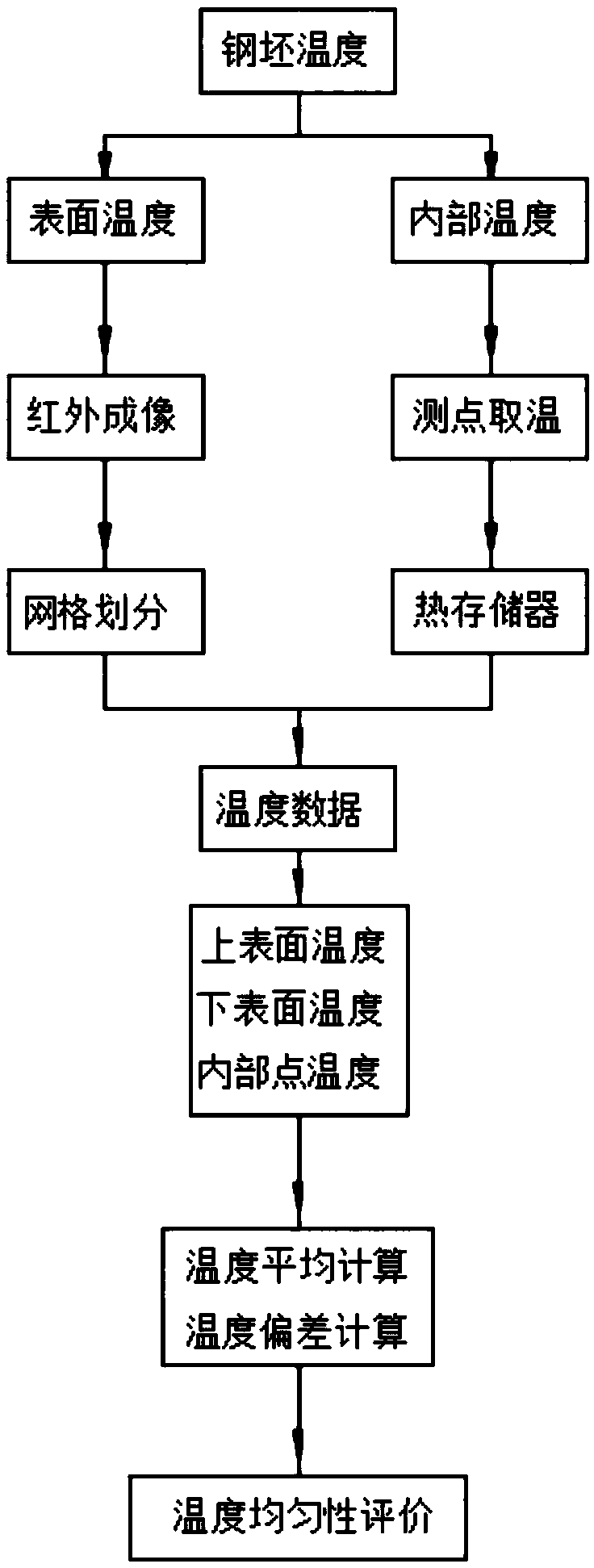

[0032] Please refer to figure 1 and figure 2 , the present embodiment provides a measuring device for the uniformity of the billet heating temperature, comprising: a lens 4, a grating 5, a detector 6 and an imaging device 7 connected to a computer 8 in sequence, and the device also includes:

[0033] The temperature recorder 3 is installed on the surface of the billet before the billet is put into the furnace;

[0034] The thermocouple is arranged at the bottom of the measuring hole 2 in the billet before the billet is put into the furnace, the upper part of the measuring hole 2 is filled with refractory material, and the thermocouple is connected with the temperature recorder 3;

[0035] Among them, during the billet heating process, the internal temperature of the billet is measured by the thermocouple, and the temperature data measured by the thermocouple is saved by the temperature recorder according to the set time step; The imaging device 7 obtains the upper surface t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com