Linear motion transmission structure for contact

A technology of transmission structure and linear motion, applied in the direction of contact drive mechanism, etc., can solve the problems of blockade of internal transmission structure, inability to be widely used, complicated design, etc., to increase the smoothness of motion, wide range of applicable pressure, and small frictional resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

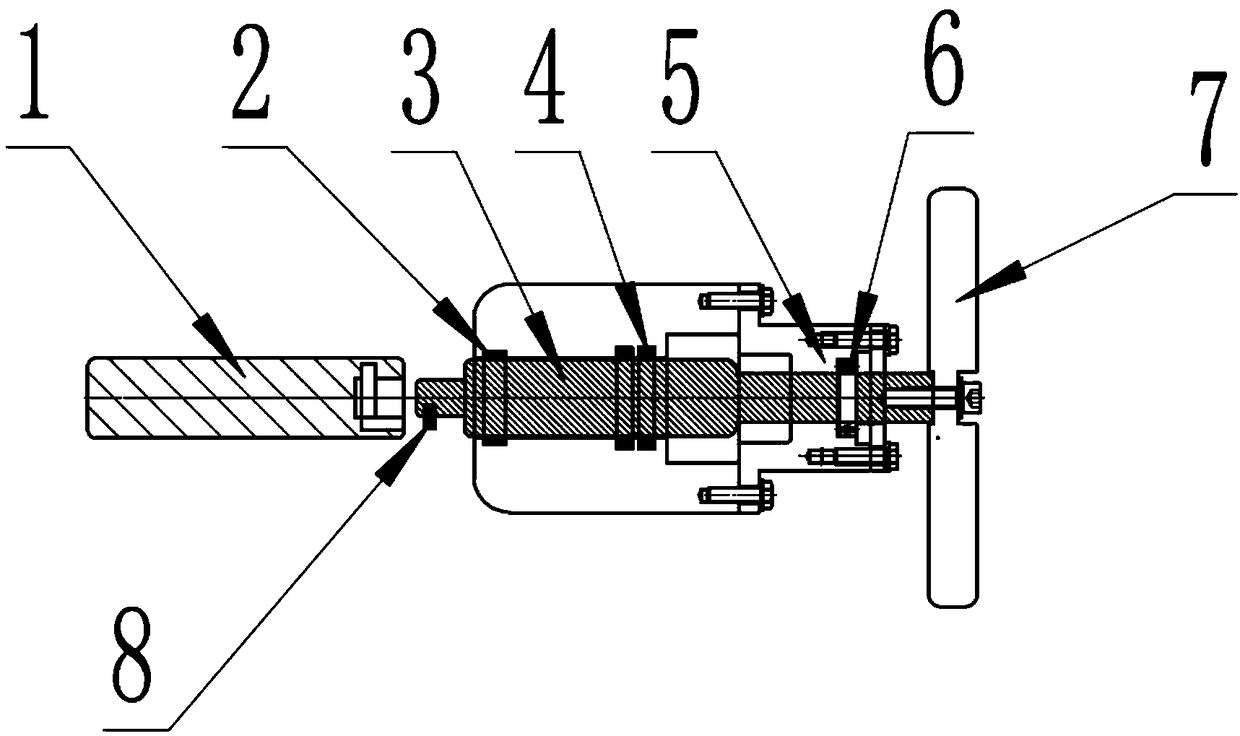

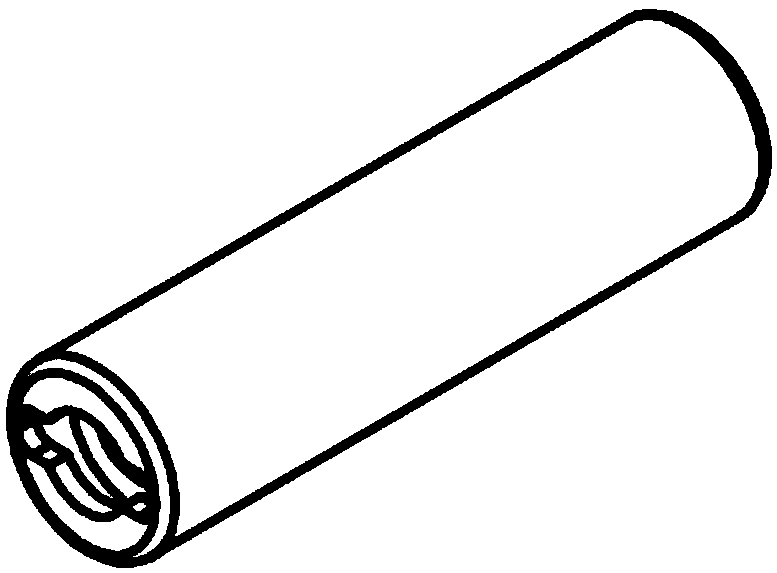

[0031] like figure 1 As shown, a contact linear motion transmission structure includes a movable contact 1, a guide 2 and a transmission shaft 3, the guide 2 is provided with a transparent sliding cavity, the transmission shaft 3 moves back and forth through the sliding cavity, and the movable contact The head 1 is located at one end of the sliding chamber, the movable contact 1 is connected to the opposite part of the transmission shaft 3, and the other end is connected to the high-voltage bus and the insulation experiment device;

[0032] When the drive shaft 3 is connected to the moving contact 1, the drive shaft 3 pulls the moving contact 1 to move, thereby switching the test state of the high-voltage bus.

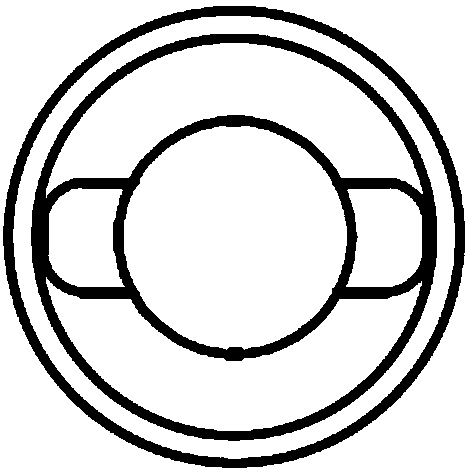

[0033] like Figure 2-4 As shown, there is a rectangular groove on the end surface of the movable contact 1, and there is an annular groove inside. By rotating the transmission shaft 3, the column pin 8 can be inserted into the movable contact 1, and the rotation angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com