Photovoltaic module heat collection device

A technology for photovoltaic modules and heat collection devices, applied in the field of photovoltaics, can solve the problems of low heat transfer efficiency, affecting photovoltaic power generation efficiency and heat collection efficiency, etc., and achieve the effects of large heat exchange area, good heat insulation, and increased heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

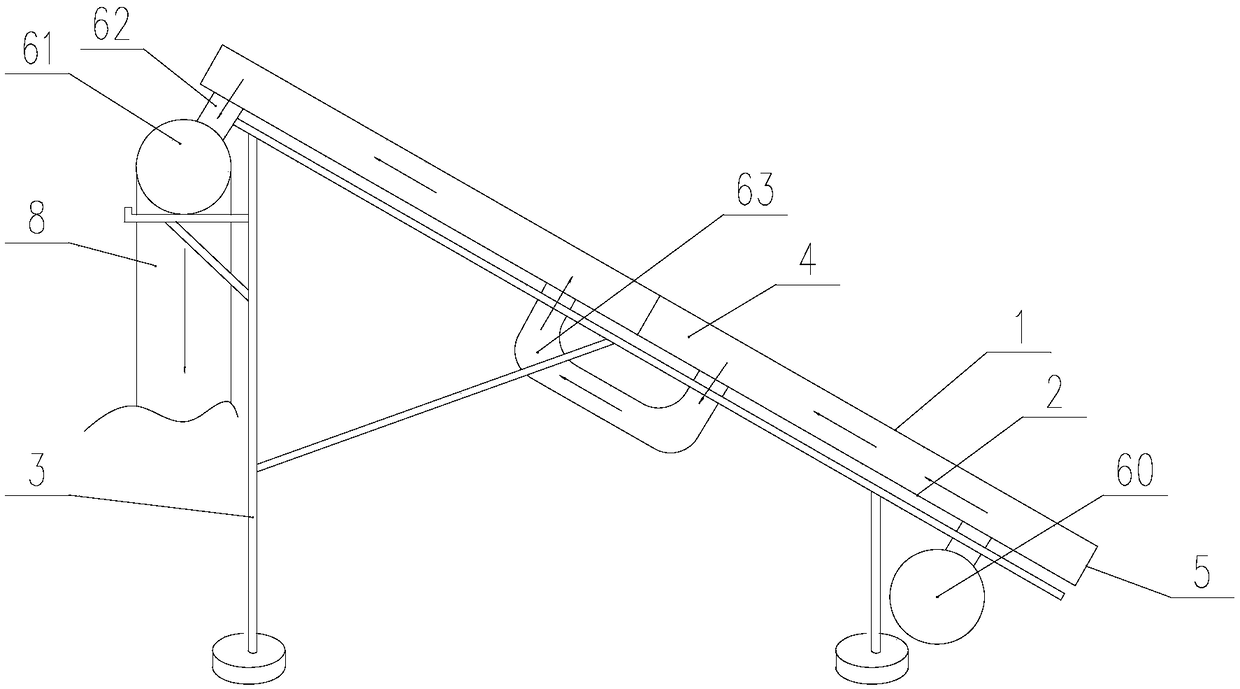

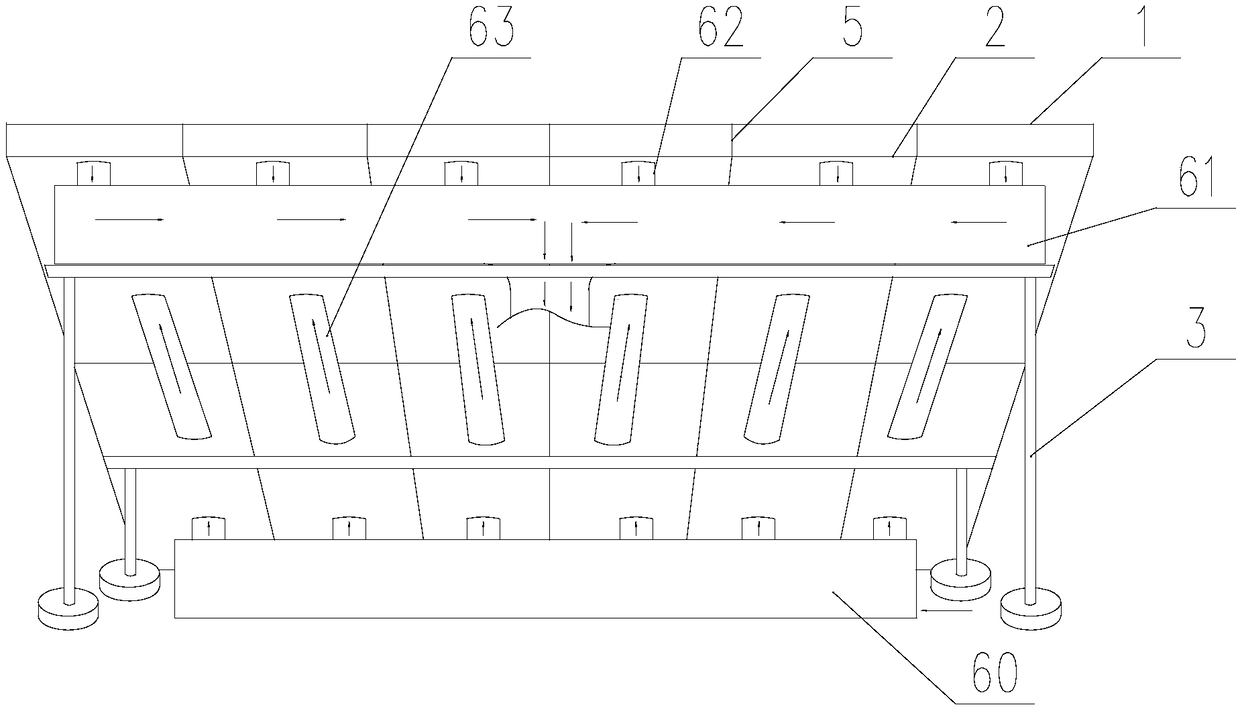

[0029] Such as figure 1 and figure 2 As shown, a photovoltaic module heat collecting device 1 includes a photovoltaic module 1, a heat collecting plate 2 and a supporting frame 3, and the photovoltaic module 1 and the heat collecting plate 2 are installed on the supporting frame 3, and the heat collecting plate 2 is connected to the heat conducting frame 5 of the photovoltaic module 1, the heat collecting plate 2, the heat conducting frame 5 and the back of the photovoltaic module 1 are surrounded to form a hollow heat exchange space 4, and the ventilation pipe 6 is connected to the heat collecting The back of the plate 2 is in communication with the heat exchange space 4, and the photovoltaic module 1 is composed of 8 single solar cells in 2 series and 6 in parallel.

[0030] Further, the material used for the heat conduction frame 5 is aluminum, and the material used for the heat collecting plate 2 is an aluminum-plastic plate.

[0031] Further, the heat collecting plate ...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the photovoltaic module 1 and the heat collecting plate 2 are obliquely installed on the support frame 3, and the ventilation duct 6 includes a The lower ventilation pipe 60 of the air inlet and the upper ventilation pipe 61 with an air outlet arranged on the inclined upper end of the heat collecting plate 2, the upper ventilation pipe 61 and the lower ventilation pipe 60 communicate with each other. After entering the inlet, the hot air will move upwards after being subjected to the backplane of the photovoltaic module 1 and the heat transfer temperature rise. Therefore, the hot air will move from the lower end to the upper end along the heat exchange space 4, and the push of the external air will accelerate the process. Movement, so that the air flowing in the heat exchange space 4 will quickly take away the heat on the back of the photovoltaic module 1 and the heat collecting plate 2, so that the heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com