Mango peeling machine

A technology of peeling machine and mango, applied in the field of mango peeling machine, can solve the problems of finger injury, hidden safety hazards, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

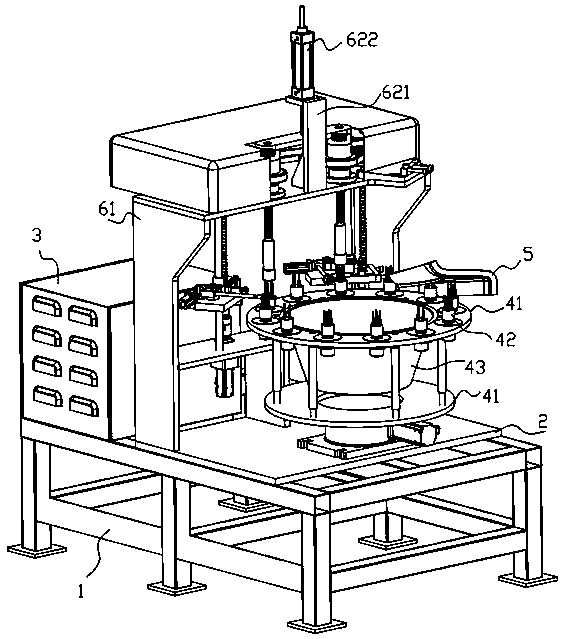

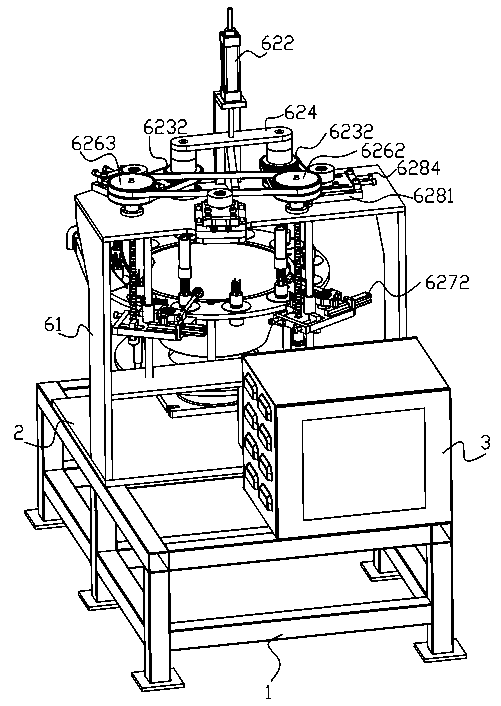

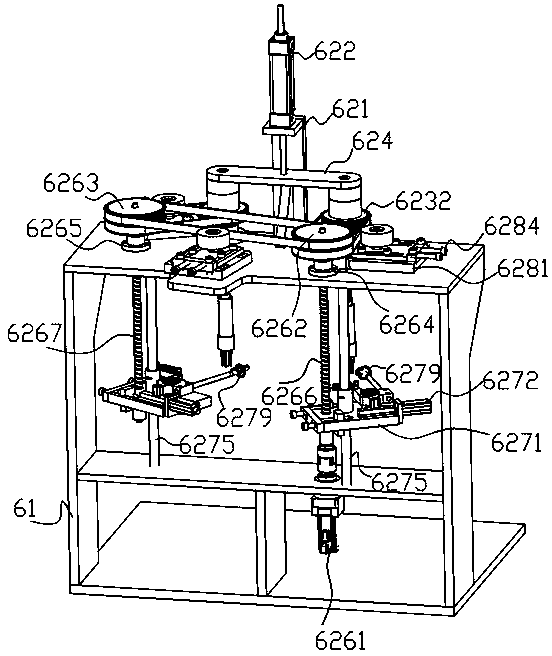

[0023] Such as Figure 1 to Figure 8As shown, a kind of mango peeling machine described in this embodiment comprises machine frame 1, base plate 2 and control electrical box 3, and described control electrical box 3 is fixed on one end of described machine frame 1, and described base plate 2 is fixed At the other end of the machine frame 1, the control electrical box 3 is used to provide the power required by each component and store the program for controlling the displacement parts;

[0024] It also includes a feeding mechanism, the feeding mechanism is installed on the base plate 2, the feeding mechanism includes an electric indexing device and a double-layer turntable 41, and the electric indexing device includes an electric indexing plate and a disc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com