Filtering device with self-cleaning function

A filter device and self-cleaning technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of large pressure fluctuations in equipment, multiple self-cleaning flows, uneven self-cleaning liquid flow, etc., to achieve Uniform flow, compact equipment structure, and the effect of reducing self-cleaning flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

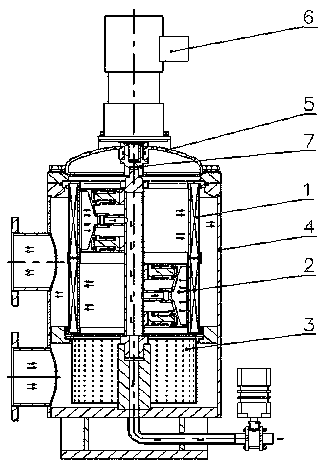

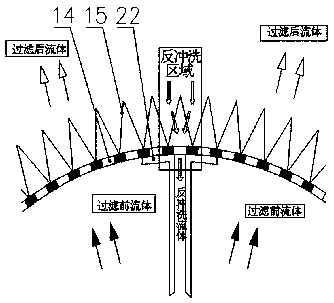

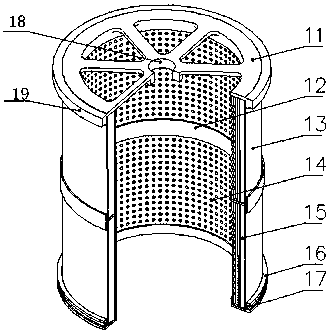

[0022] A filter device with self-cleaning function, comprising a tank body 4, the upper end of the tank body 4 is provided with an upper cover assembly 5, such as Figure 1-Figure 7 As shown, the tank body 4 is provided with a self-cleaning filter element 1, the self-cleaning filter element 1 is provided with a suction cup assembly 2, and the lower end of the self-cleaning filter element 1 is provided with a pre-filter filter element 3, and the upper end of the suction cup assembly 2 is connected by a connecting shaft 7. The geared motor 6 is fixedly installed on the upper end of the upper cover assembly 5; the tank body 4 includes a cylinder 42 placed on the upper end of the mounting seat 49, the upper end of the cylinder 42 is provided with an end cover 41, and the side wall of the cylinder 42 is provided with oil The inlet 44 and the oil outlet 43. The oil inlet 44 is located on the lower side of the oil outlet 43. The position on the inner wall of the cylinder 42 between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com