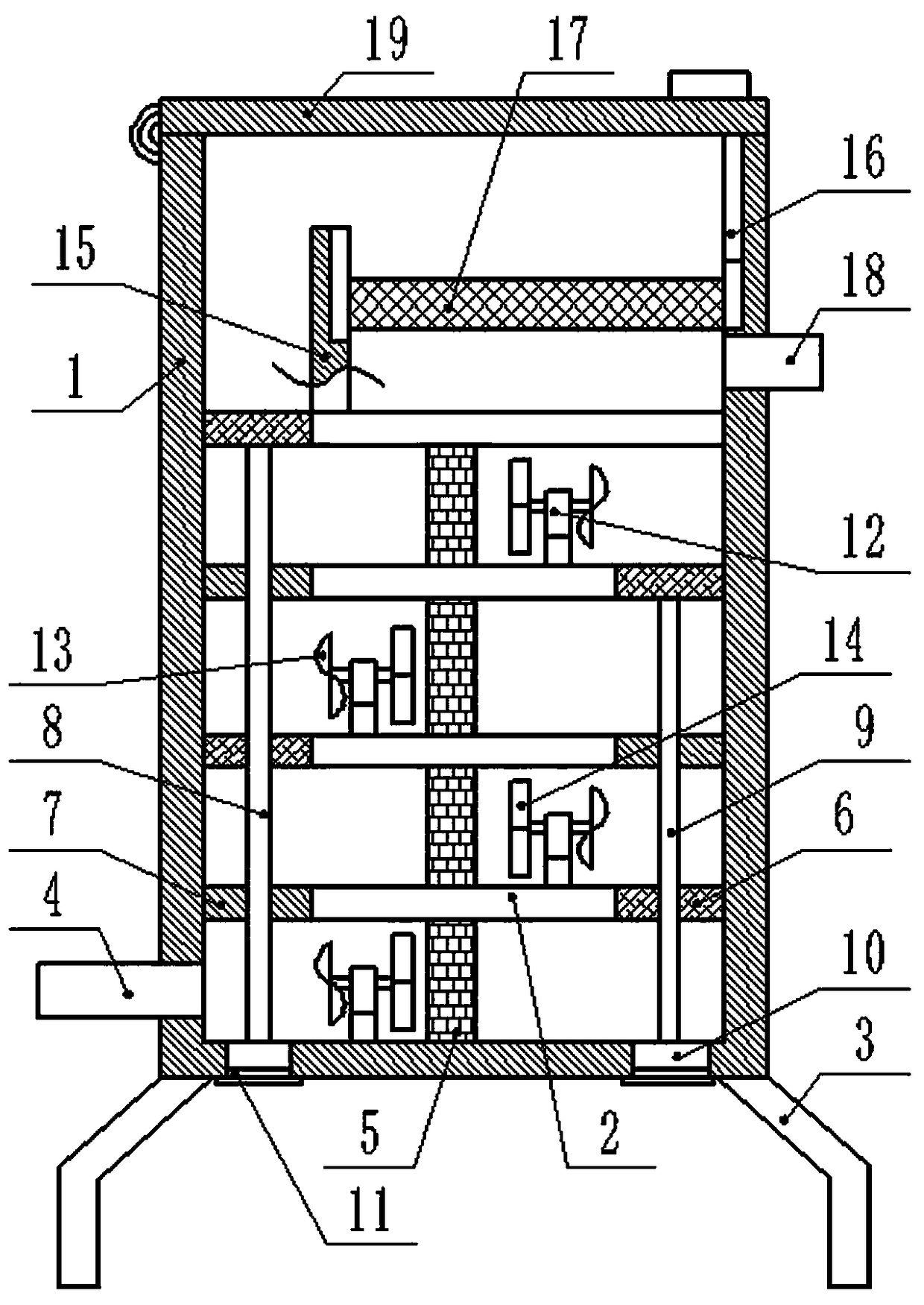

High-efficiency multi-layer electrostatic precipitator

An electrostatic precipitator and high-efficiency technology, which is applied in electrostatic separation, electrostatic effect separation, electrode structure and other directions, can solve the problems of affecting the dust removal effect of electrostatic precipitators, the inability to collect by the collecting plate, and increasing the burden of land use, so as to improve the electrostatic precipitator effect, Small footprint and improved charge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

[0012] See figure 1 , A high-efficiency multilayer electrostatic precipitator, comprising a box body 1 and a partition plate 2, the lower end of the box body 1 is fixedly connected with a number of feet 3, the lower end of the left side of the box body 1 is connected with an air inlet pipe 4, the partition The plate 2 is provided with a plurality of equidistant and even fixed connections in the box body 1. The electrode mesh plate 5 is fixedly connected between the lower end of the partition plate 2 and the lower partition plate 2 and the bottom plate of the box body 1. There is an opening on the left side of the upper partition plate 2, and the other partition plates 2 have openings on both sides. The electrode dust collecting net 6 and the baffle 7 are tightly connected in the openings through sealing gaskets, and the electrode dust collecting nets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com