Tubular ultrasonic brackish water desalination equipment and method thereof

A brackish water desalination and ultrasonic technology, applied in chemical instruments and methods, water/sewage treatment equipment, water/sewage treatment, etc., can solve the problems of high cost, high energy consumption of desalination equipment, complicated maintenance, etc., and achieve extremely easy Effect of replacement, long service life, and improvement of desalination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

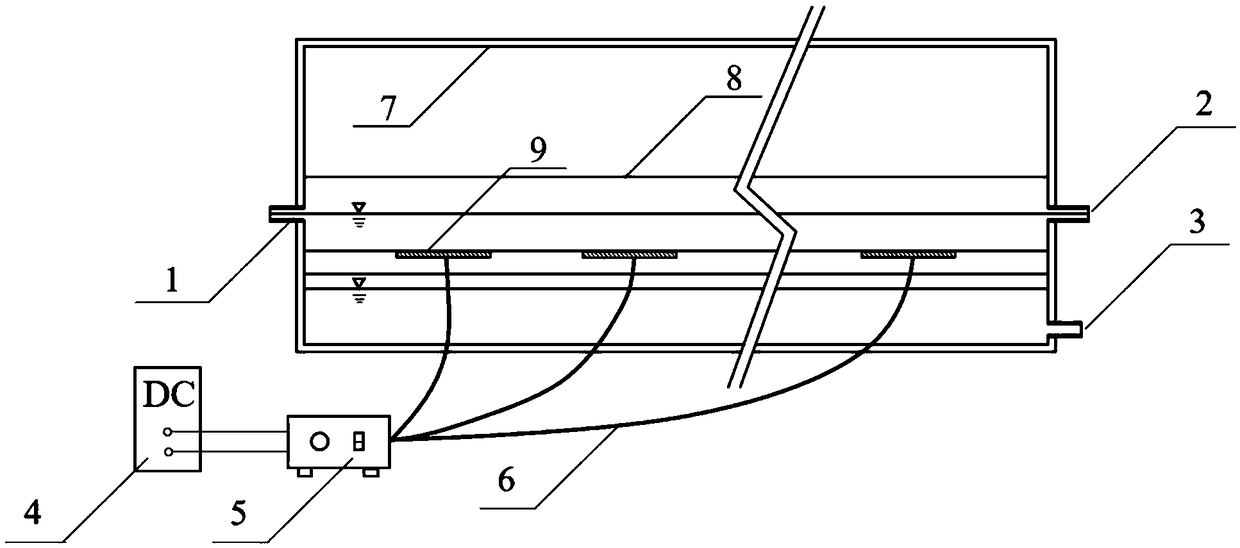

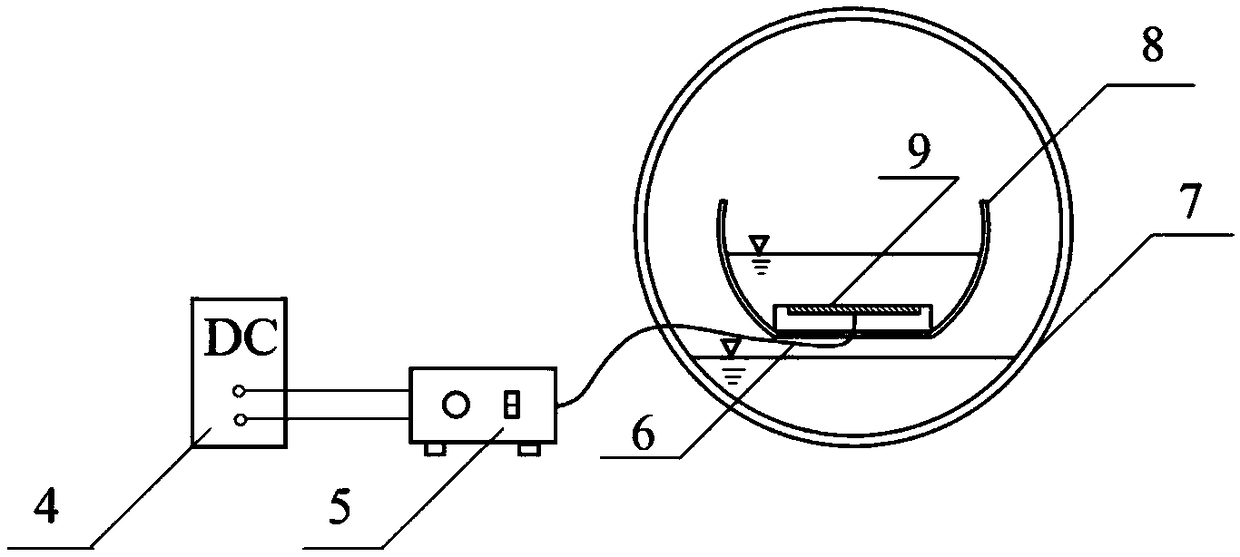

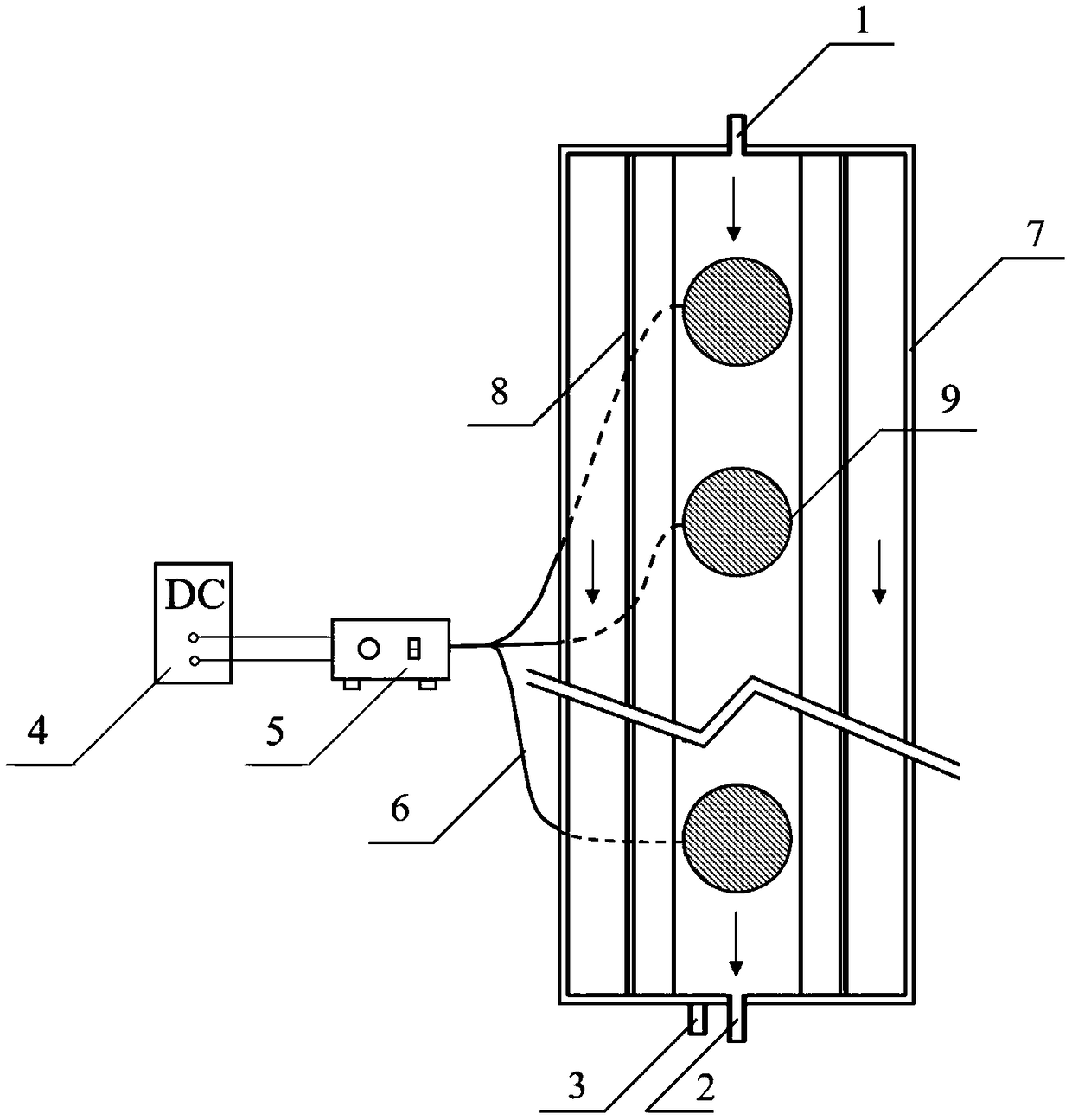

[0032] 实施例1:一种管式超声波苦咸水淡化设备

[0033] Depend on Figure 1 ~ Figure 3 所示,本发明的管式超声波苦咸水淡化设备包括:包括稳压流电源4、控制器5、电线6、冷凝外管7、雾化内管8和超声波雾化片9;所述稳压流电源4置于所述管式超声波苦咸水淡化设备的外部;所述控制器5置于所述管式超声波苦咸水淡化设备的外部并与所述稳压流电源4连接;所述电线6连接超声波雾化片9和控制器5;所述冷凝外管7为封闭圆筒状,将雾化内管8和超声波雾化片9包于其内,冷凝外管7的底端是处理后的清水;所述雾化内管8置于冷凝外管7内部,内置有超声波雾化片9,苦咸水在雾化内管8流动;所述超声波雾化片9间隔置于所述雾化内管8内部的底端。

[0034] 进一步,上述管式超声波苦咸水淡化设备的左侧设有进水口1,右侧设有高盐水出口2和清水出口3,其中所述高盐水出口2设于清水出口3的上方。

[0035] 进一步,上述稳压流电源4的电压是28V~50V直流电压。

[0036] 进一步,上述超声波雾化片9采用铜制圆形电极中间放入压电陶瓷介质材料制成,为圆盘形,直径5mm~50mm。

[0037] 进一步,上述超声波雾化片9置于苦咸水液面以下1.7~2.0cm。

[0038] 进一步,上述控制器5内设三极管、电容、电阻,构成电容三点式振荡器。

[0039] 进一步,上述超声波雾化片9通过电线6与三极管、电容、电阻形成正反馈谐振电路,将电能转化为弹性机械振动波,进而使液体发生雾化逸出。

[0040] 进一步,上述三极管优选为BU406三极管。

[0041] 具体地,上述管式超声波苦咸水淡化设备主体总长53.3cm,其中管壁厚0.4cm,内部工作长度52.5cm,每间隔2.5cm设置直径为2.5cm,厚度为0.2cm的超声波雾化片,共计设置10个超声波雾化片于液面以下1.7~2.0cm;冷凝外管内径为8cm,壁厚0.4cm,雾化内管内径5cm,壁厚0.2cm。

Embodiment 2

[0042] 实施例2:一种苦咸水淡化的方法

[0043] combine figure 1 —— image 3 , the brackish water desalination method is described, the desalination method includes: the brackish water enters the tubular ultrasonic brackish water desalination equipment from the water inlet 1, and flows in the atomizing inner tube 8; the ultrasonic atomizing sheet 9 passes through the electric wire 6 and the triode, capacitor, and resistor in the controller 5 form a positive feedback resonance circuit. Under the action of the regulated current power supply 4, the ultrasonic atomizing sheet 9 generates high-frequency oscillations to atomize the brackish water in the atomizing inner tube 8 , into water mist; the water mist touches the condensing outer tube 7 and condenses again during the process of floating up, and the condensed clean water is discharged from the clear water outlet 3 through the inner wall of the condensing outer tube 7; discharge.

Embodiment 3

[0044] Example 3: Desalination experiment of brackish water

[0045] (1) Manual preparation of brackish water: by adding NaCl to distilled water, simulated brackish water was prepared, and the brackish water had a salt content of about 2000 mg / L and a pH of 6.8.

[0046] (2) Brackish water desalination experiment: The influent flow rate of the brackish water prepared above was controlled at 4.5 L / h, and the tubular ultrasonic brackish water desalination device described in Example 1 was continuously operated for 48 hours.

[0047] (3) Experimental results: A total of about 200L of desalinated clear water was produced, the salt content of the obtained clear water was 50±10mg / L, the pH was 7.2±0.1, and about 15L of high For salt wastewater, the treatment efficiency is: 200 / (200+15)*100%=93.02%; the equipment only needs about 48kWh / m 3 energy consumption, while the commonly used heating distillation desalination method requires about 800kWh / m 3 energy consumption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com