Microalloyed high-strength high-plasticity non-magnetic steel plate and manufacturing method thereof

A technology of micro-alloying and manufacturing method, applied in the field of non-magnetic steel sheet and its manufacturing, can solve the problems of easy generation of reticulated carbides, complex production process, high production cost, and achieve reasonable composition and process design, large scope, and low cost. The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

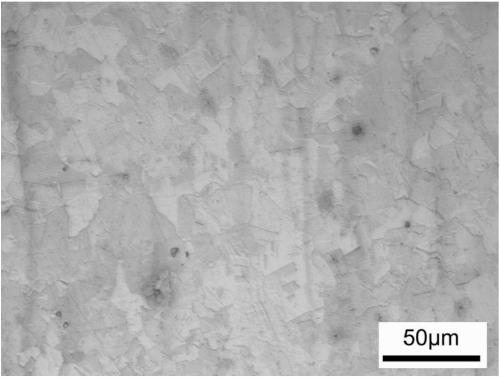

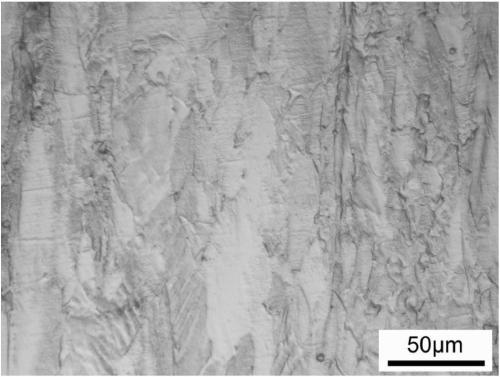

Image

Examples

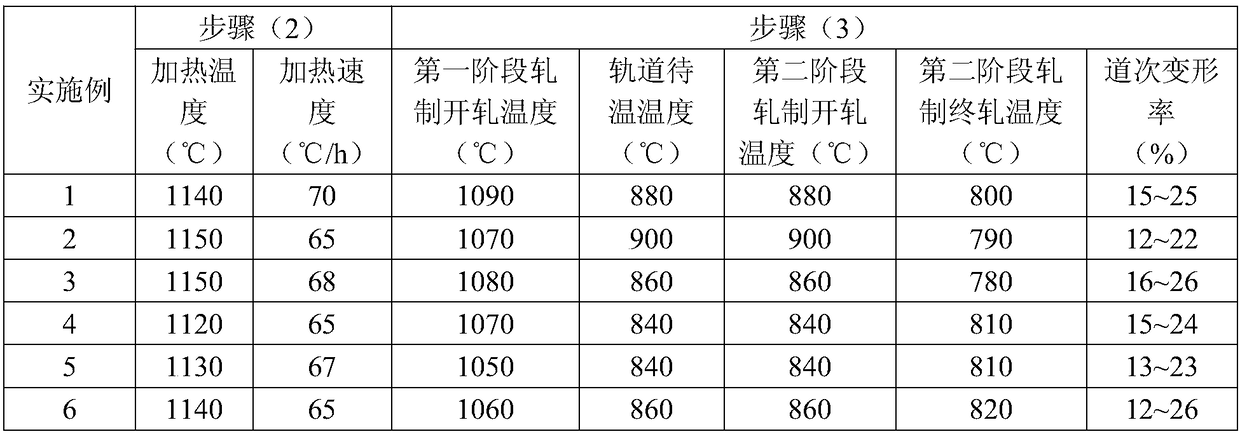

Embodiment 1-6 and comparative example 1

[0043] Table 1 lists the mass percentages of each chemical element in the microalloyed high-strength and high-plasticity non-magnetic steel sheets of Examples 1-6 and the prior art steel sheet of Comparative Example 1.

[0044] Table 1. (wt%, the balance is Fe and other unavoidable impurities except P and S)

[0045] Example

C

Si

mn

P

S

Al

Ti

Nb

1

0.16

0.23

25.78

0.007

0.005

2.08

0.011

0.043

2

0.11

0.26

22.88

0.006

0.0009

2.44

0.018

0.072

3

0.15

0.22

23.14

0.008

0.002

2.88

0.018

0.069

4

0.19

0.28

20.86

0.006

0.005

2.26

0.02

0.088

5

0.14

0.21

25.56

0.007

0.0009

2.35

0.016

0.049

6

0.17

0.31

24.38

0.008

0.003

2.78

0.012

0.071

comparative example

C

Si

mn

P

S

Al

Ti

Nb

1

0.15

0.33

21.52

0.009

0.003

2.6

—

— ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com