A yield estimating method for a continuously produced coiled material

A production volume and yield technology, applied in the direction of optical testing defects/defects, etc., can solve the problems of reducing product quality, low accuracy of estimated yield, and reduced accuracy, so as to improve production quality, improve product yield, Accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

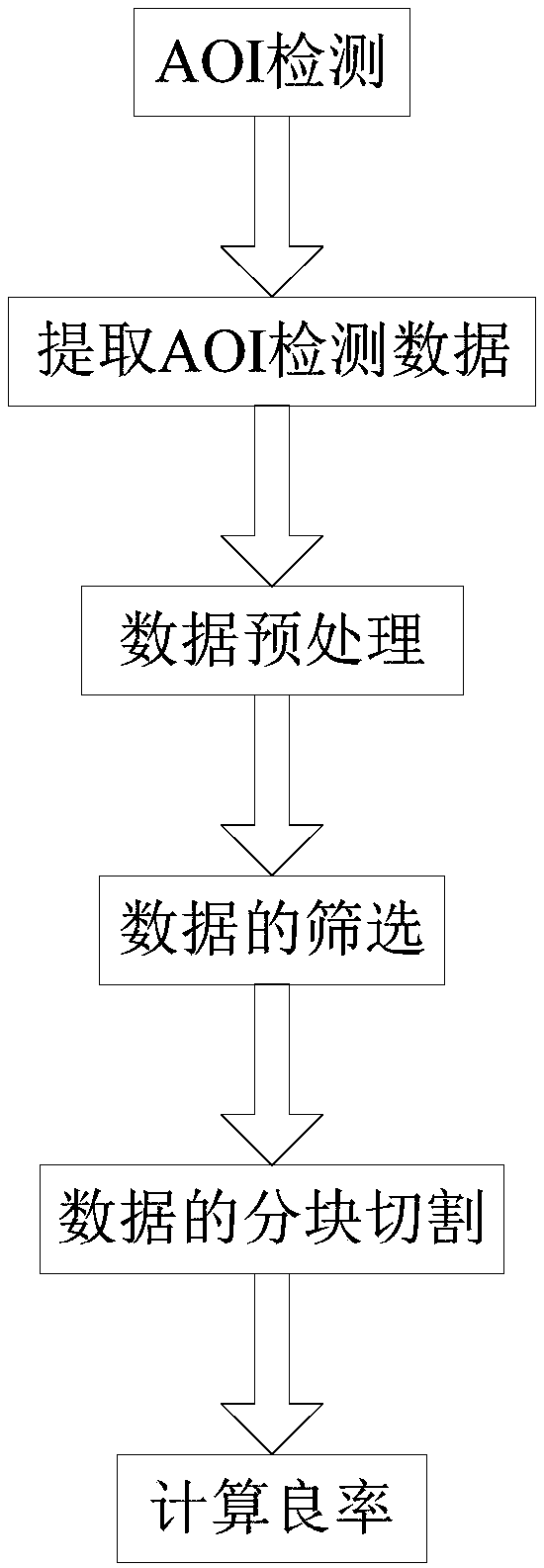

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

[0040] Glossary:

[0041] AOI (Automatic Optic Inspector): automatic optical detector;

[0042] Md Pos (Machine direction Position): the position of the defect in the direction of film movement;

[0043] CdPos (Cross direction Position): the position of the defect in the vertical direction of film movement;

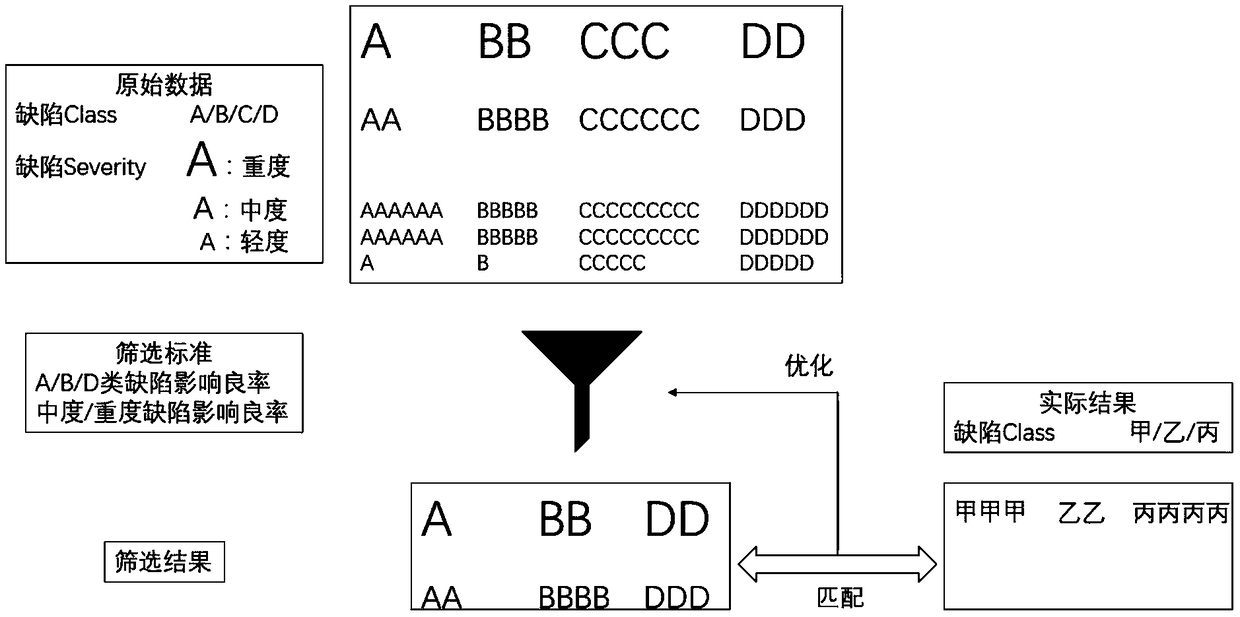

[0044] Class: the category of the defect;

[0045] Severity: the severity of the defect;

[0046] Slicing: After the production of the coil is completed, it needs to be matured for a period of time (7-10 days). After the mature, it needs to be cut into slices in a certain direction and size according to the requirements of the end customer;

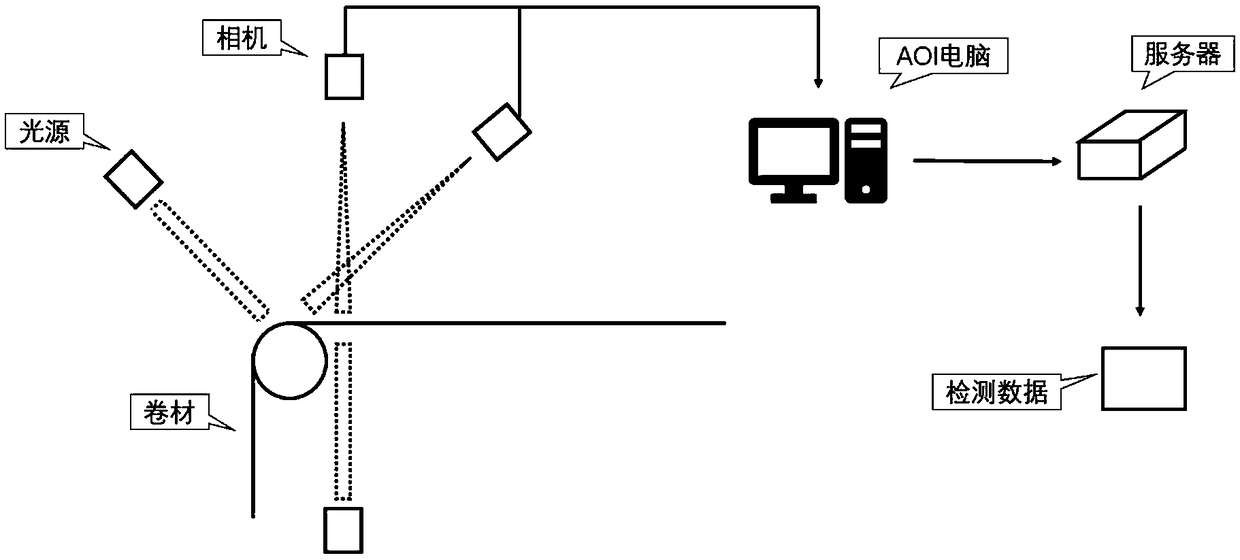

[0047] AOI is a device for real-time detection of defects encountered in coil production based on optical principles. It consists of imaging devices such as light sources, lenses, and CCDs, and back-end computer acquisiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com