Omni-directional mowing machine with automatic obstacle avoidance for ridging type orchard

A lawnmower and ridge-type technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of difficult mowing, low efficiency, complex environment, etc., and achieve the effect of improving mowing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

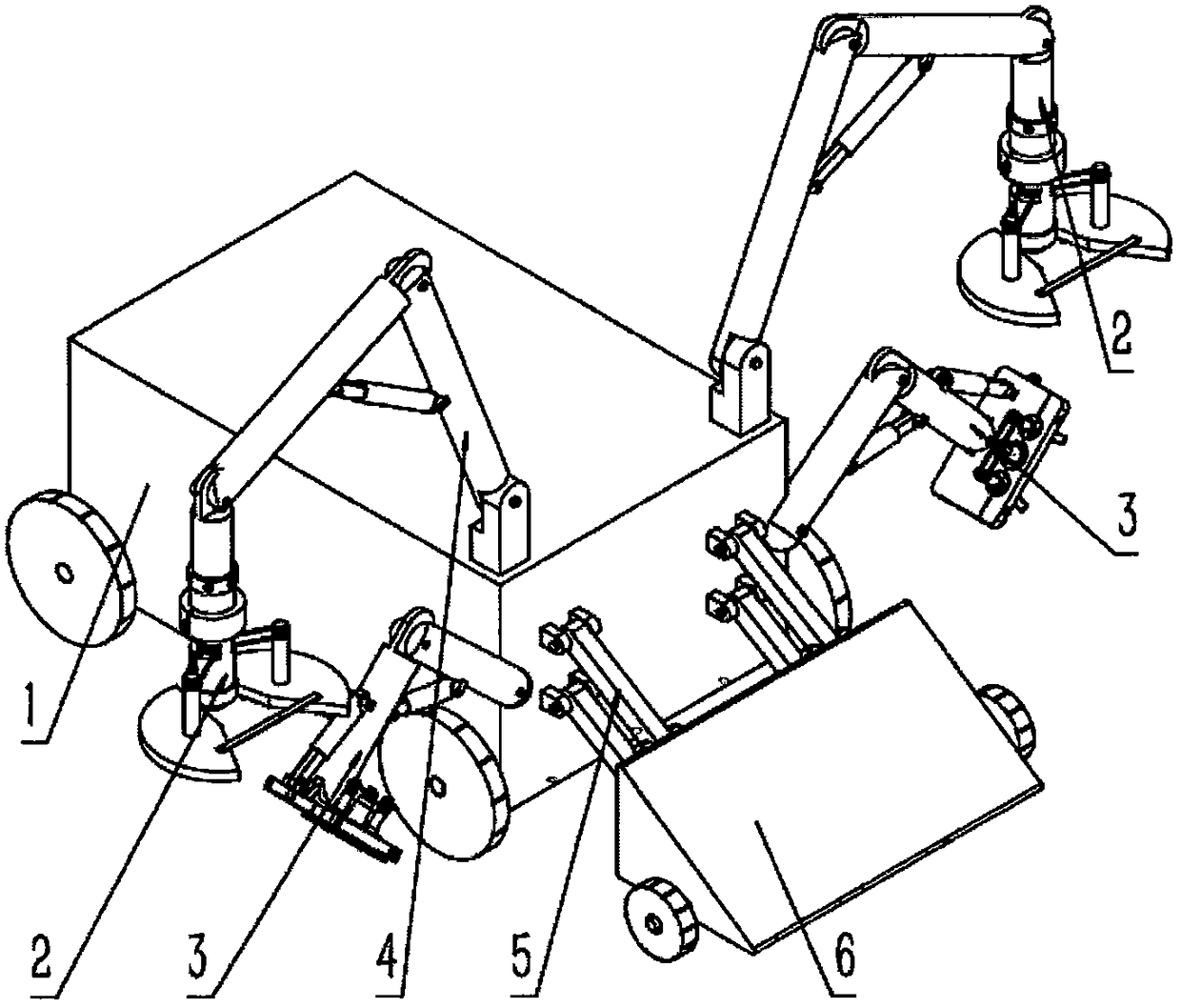

[0022] The following is attached figure 2 one attached Figure 8 The specific implementation manner will be further described.

[0023] Orchard mower of the present invention comprises: furrow surface cutter 6, 2 ridge slope surface cutters 3 and 2 ridge top surface cutters 2.

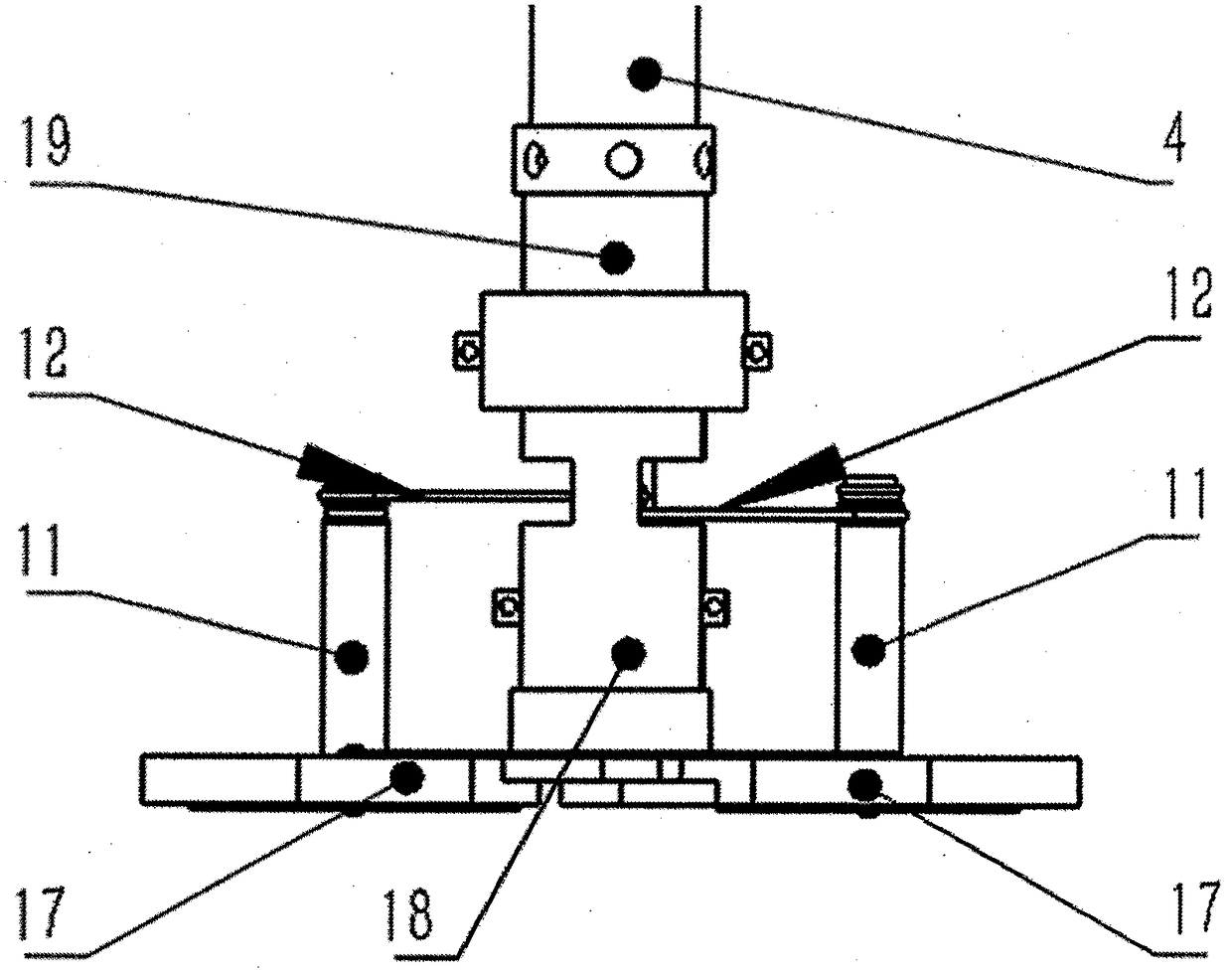

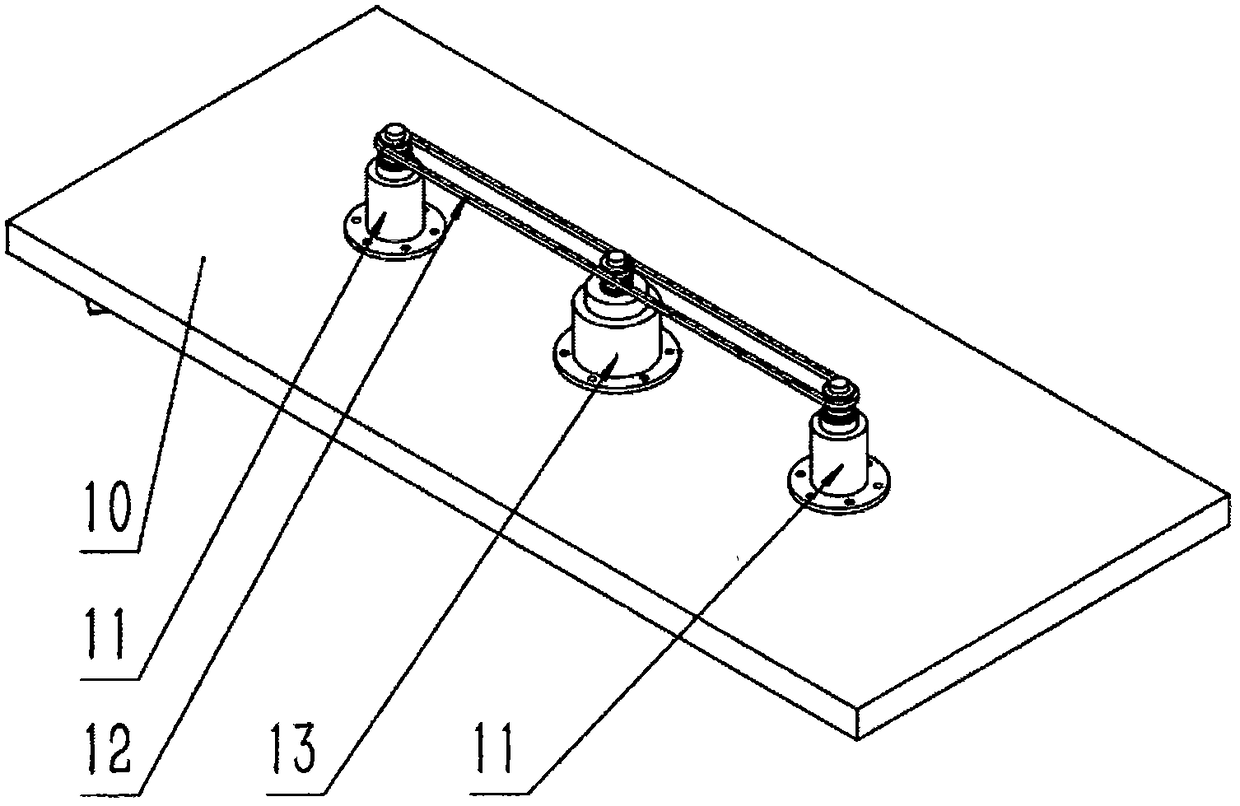

[0024] Described ditch face cutter 6 comprises: four-bar mechanism 5, ditch face cutter housing 7, profiling wheel 8, cutter 9, ditch face cutter base plate 10, drive shaft 11, belt 12, drive motor 13, drive shaft 14. The specific implementation method is provided by the appended figure 2 one attached Figure 4 shown.

[0025] as attached figure 2 As shown, it is characterized in that the transmission motor 13 is fixed on the bottom plate 10 of the ditch surface cutter by bolts, the transmission shaft 11 is connected with the bottom plate 10 of the ditch surface cutter through a bearing, and the transmission motor 13 transmits power to the transmission drive through a belt 12. Axis 11.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com