Energy-saved steel pipe cutting device

A technology for cutting devices and steel pipes, which is applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc., which can solve problems such as low application value, insufficient processing accuracy, and deviation of incision positions, and achieve easy application and practical value High, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

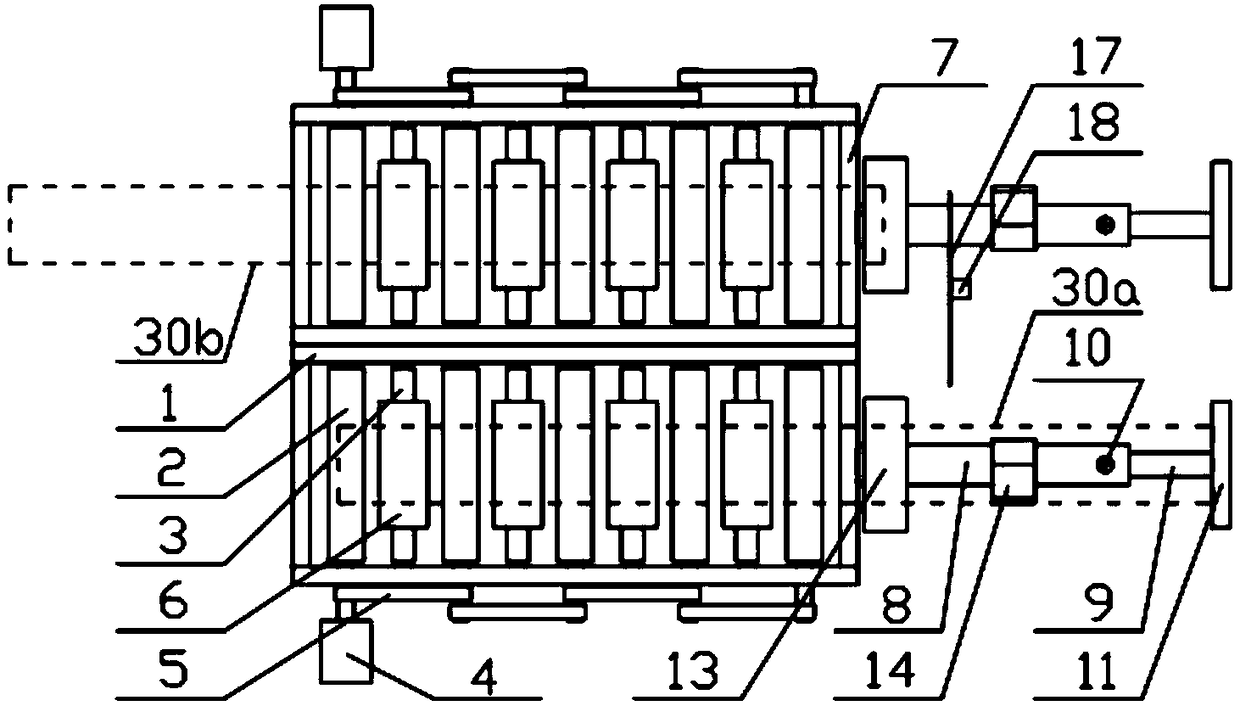

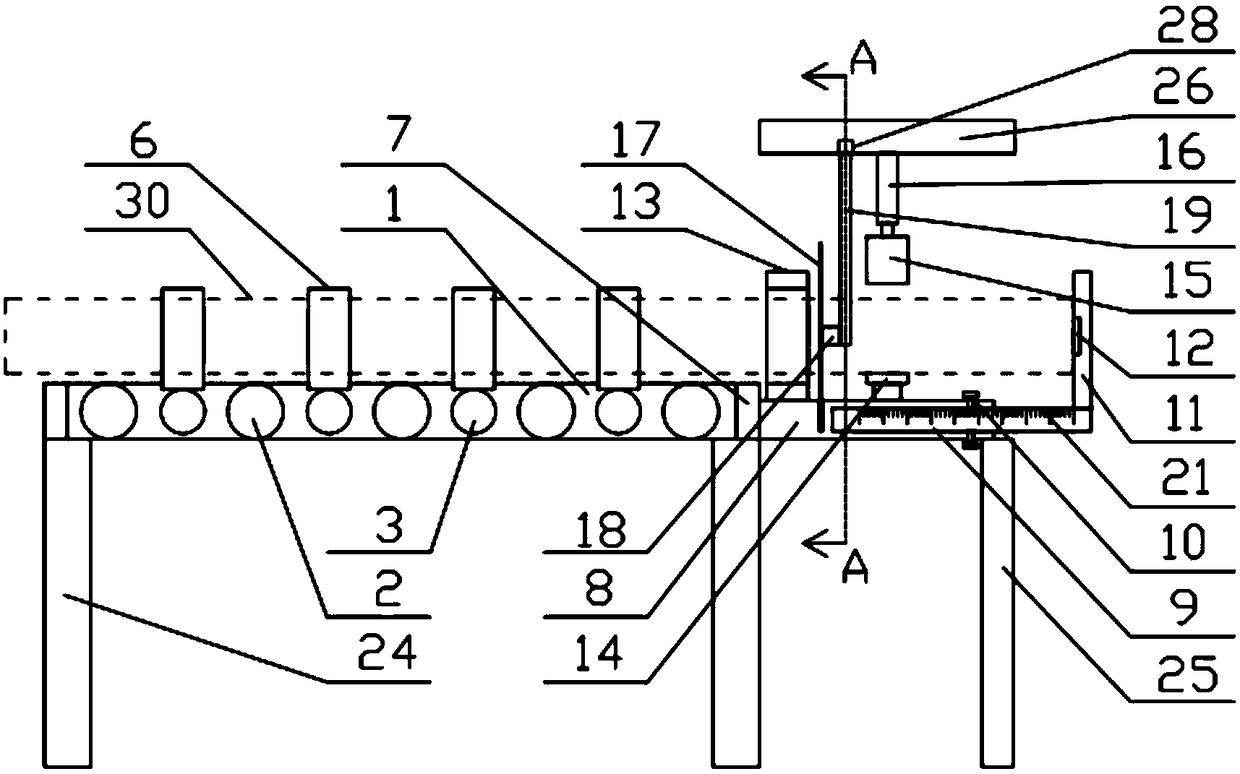

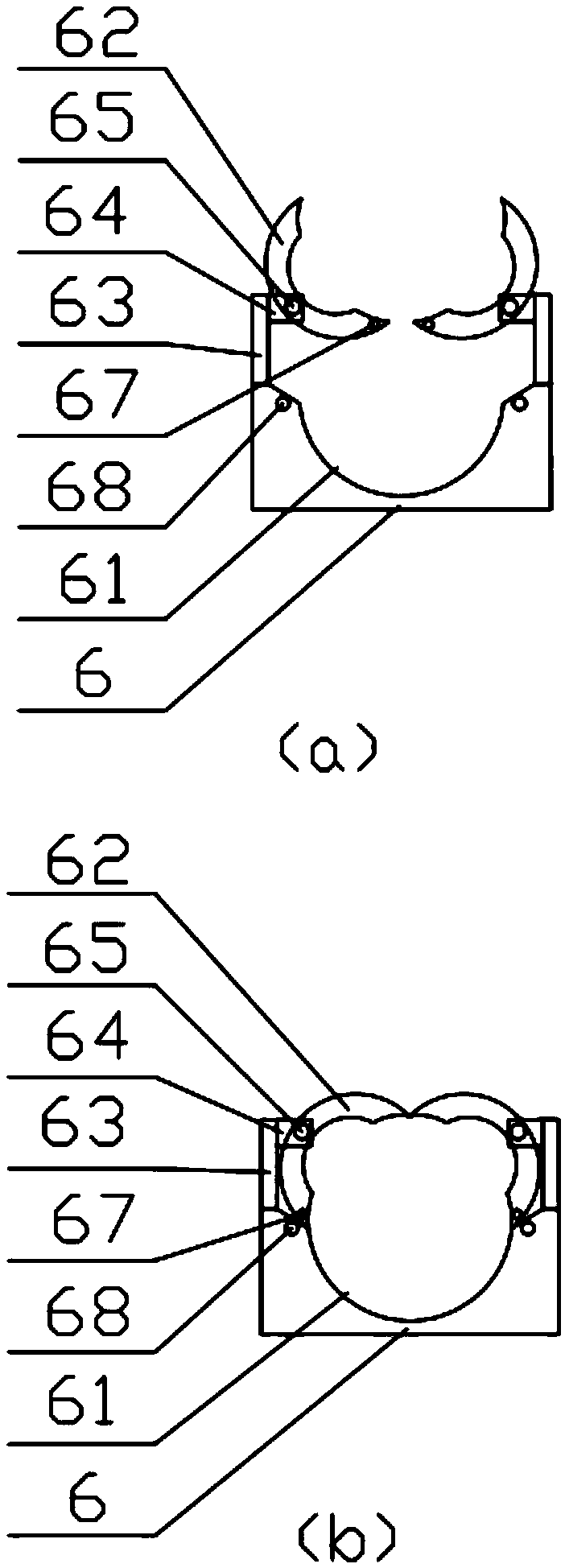

[0034] Such as figure 1 and figure 2 The shown energy-saving steel pipe cutting device includes two sets of stations for cutting steel pipes arranged side by side and a cutting mechanism reciprocating between the two sets of stations. One set of stations includes a frame, a conveyor roller row , limit adjustment components and clamping mechanism,

[0035] The conveying roller row comprises two strip-shaped frame plates 1 arranged oppositely and push roller shafts 2 and supporting roller shafts 3 which are vertically connected between the two shaped frame plates 1 and are alternately arranged at intervals. In order to push the roller shaft 2, the two ends of the push roller shaft 2 are inserted and rotatably installed on the strip frame plate 1 of the corresponding side respectively, and one end passes through the corresponding strip frame plate 1 and is placed on the strip frame plate 1. The outer side forms a driving part, the driving part of the pushing roller shaft 2 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com