Hard alloy sleeve type part inner hole key groove machining method

A technology of cemented carbide and processing methods, which is applied in the field of mechanical processing, can solve problems such as difficult to meet the high-precision requirements of keyway width, and achieve the effect of ensuring smooth processing, ensuring dimensional accuracy, and facilitating later assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] This embodiment takes the processing of the keyway in the inner hole of a cemented carbide sleeve as an example to give a detailed explanation of the method for machining the keyway in the inner hole of the cemented carbide bushing parts provided by the present invention.

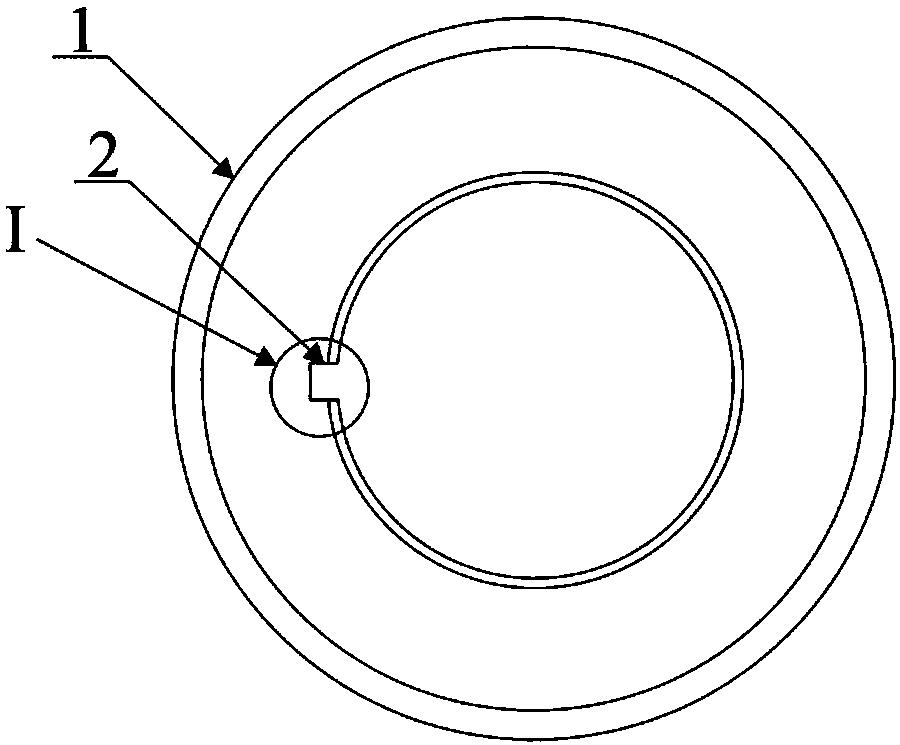

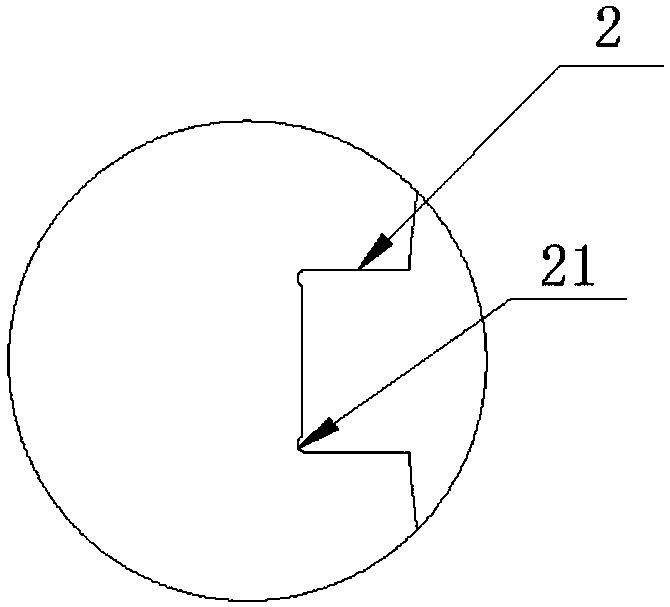

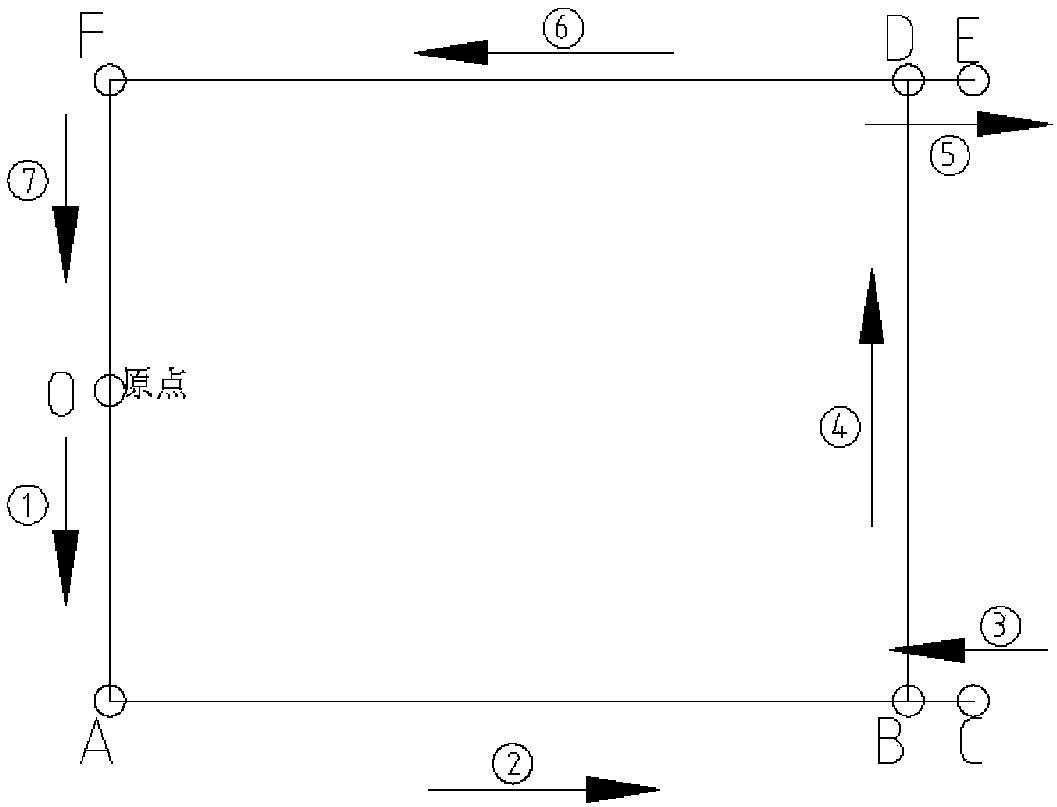

[0029] In this embodiment, it is necessary to process the hard alloy bushing with keyway in the inner hole, such as figure 1 and figure 2 As shown, a keyway 2 is designed on the inner hole of the cemented carbide bushing 1, and the cross section of the keyway 2 is rectangular, including the opposite first side, the second side and between the first side and the second side, the first An air getter 21 is designed on the third side where the side is connected to the second side, and where the first side, the second side and the third side are connected. In this embodiment, the depth machining amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com