Automobile shaft head assembly welding device

A technology for automobile axles and assemblies, which is applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., and can solve the problems of less surface protection of workpieces and welding slag splashes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

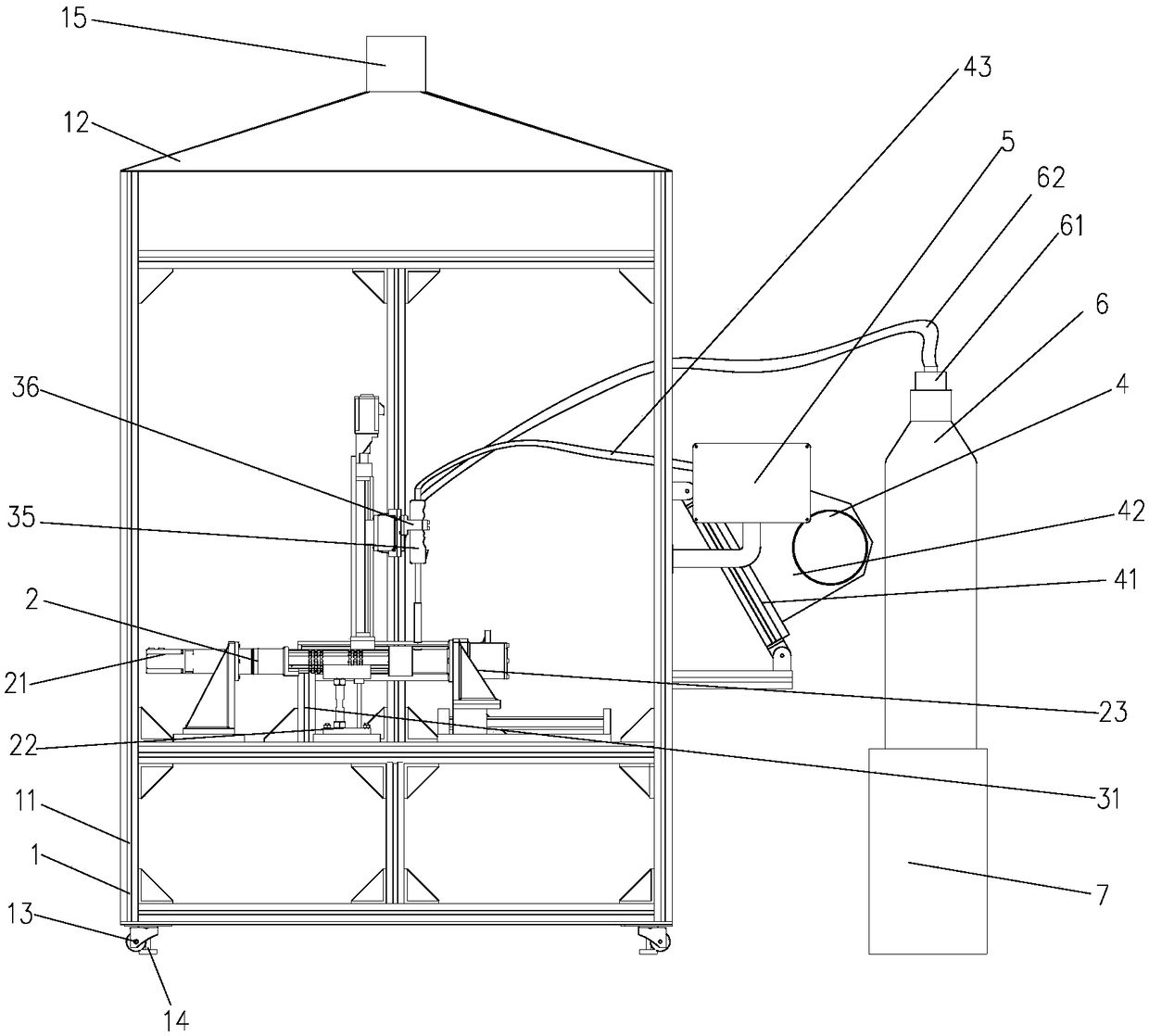

[0031] Such as Figure 1-5 As shown, a device for welding the axle head assembly of an automobile includes an equipment box 1, a clamping system 2 arranged in the equipment box 1, a welding torch adjustment device 3 and a wire feeding system 4;

[0032] The equipment box 1 comprises a box body 11, a smoke collecting hood 12 arranged on the top of the box body 11 and a plurality of running devices 13 and a plurality of fixing mechanisms 14 arranged at the bottom of the box body 11, and the box body 11 includes an upper working chamber, In the lower tool cavity, the top of the smoke collecting hood 12 is provided with a smoke exhaust fan 15;

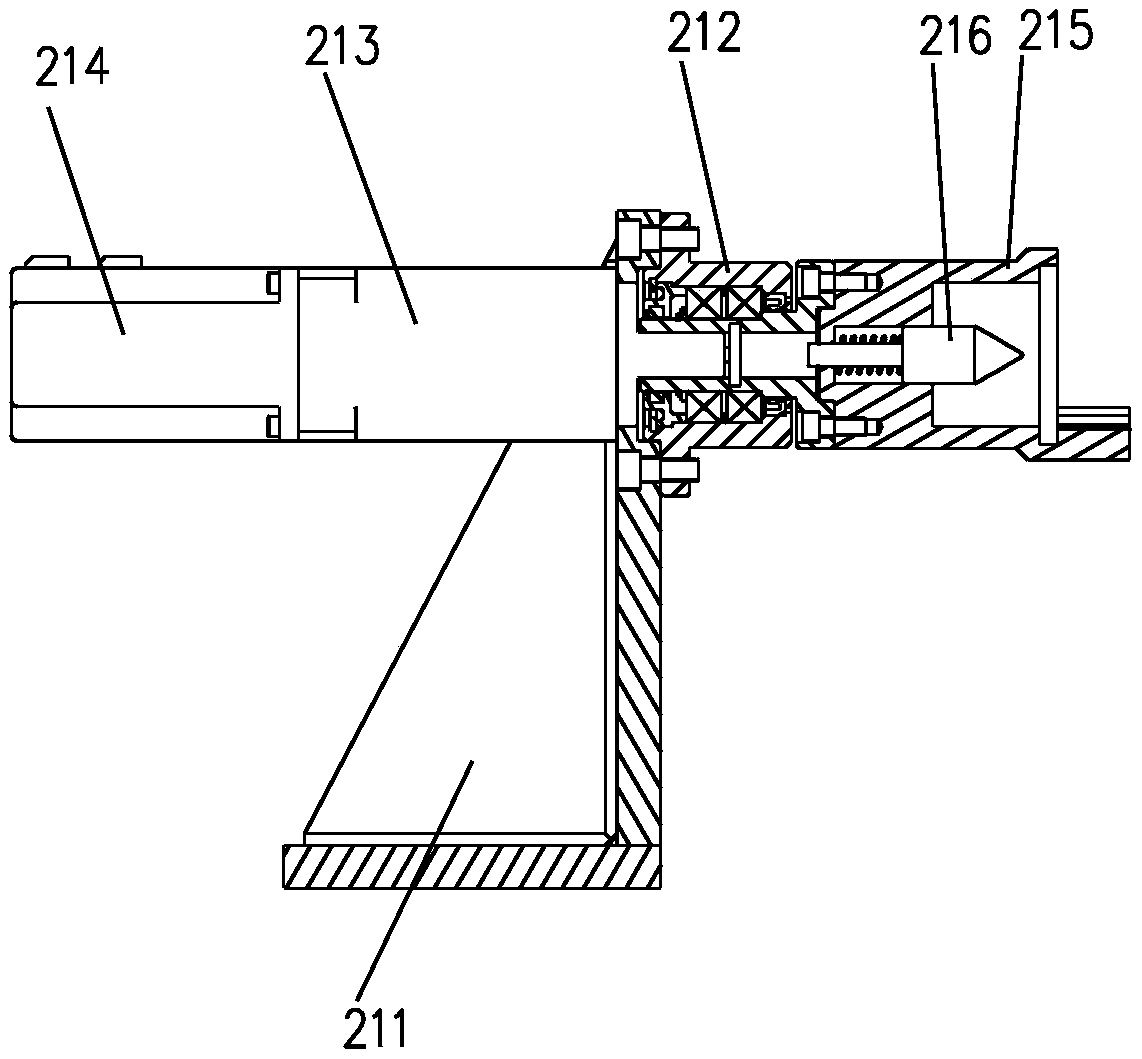

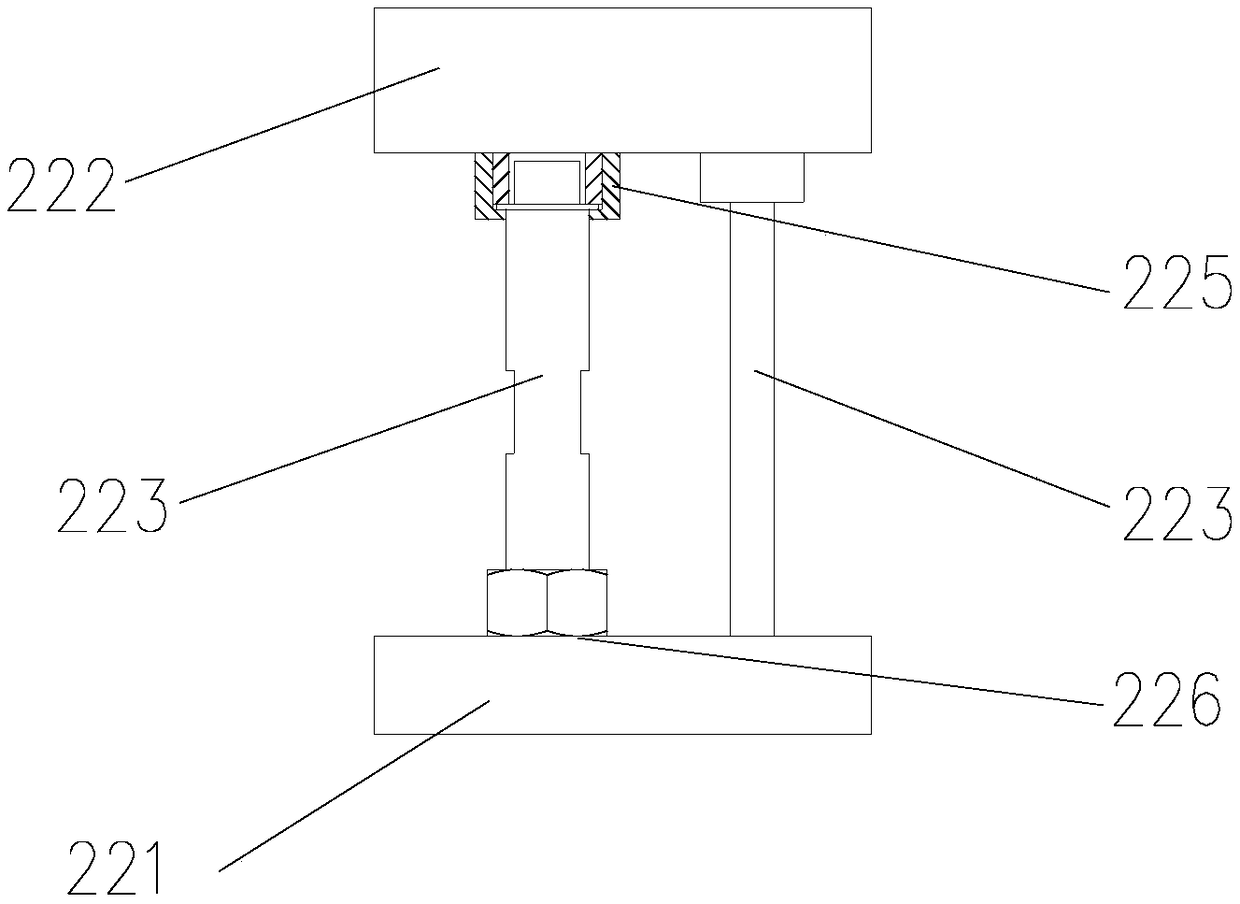

[0033] The clamping syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com