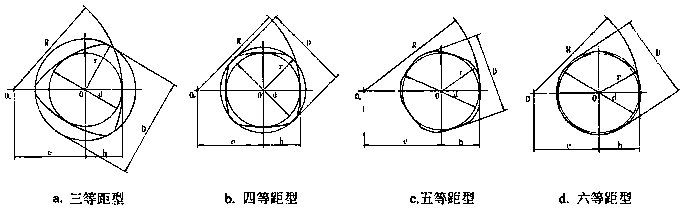

Equidistant arc surface and machining device

A circular arc surface and equidistant technology, which is applied in the field of distance circular arc surfaces and processing devices, can solve problems such as difficulty in machining circular arc surfaces, difficulty in machining, and inability to measure equidistant circular arc radii online.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

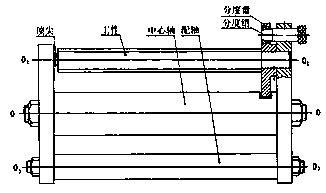

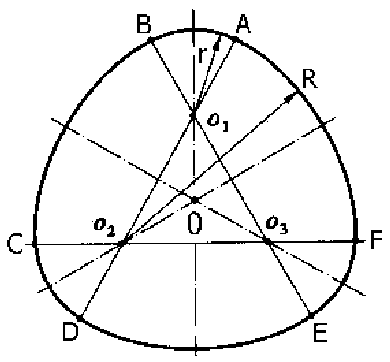

[0024] Take the Shenyang Mint Company as an example to process a batch of four equidistant circular arc surface swing shafts and sliding sleeve shafts on a batch of "labeling machines" (see Figure 5 ).

[0025] On the lathe, turn the equidistant arc square axis and the small arc outer circle into φ18 -030 (radius r=9), the φ14 -0.027 Turn into φ14.5, and then use the cylindrical grinder to grind φ14 -0.027 Grind out. Install the parts after rough turning on the top of the left end of the fixture, and the right end φ14 -0.027 It is installed in the center hole φ14K6 of the "index plate" and fixed with a top screw (see Image 6 ).

[0026] Install the fixture together with the workpiece on the lathe, and use the top of the lathe to support the top hole on the "central shaft" at both ends, so that the arc square shaft is in an eccentric position. Eccentricity e =00 1 =44-7.5=36.50. Use the "pull disc" on the lathe chuck to pull the fixture to rotate, and first rough turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com