Remanufacturing method for machining bolt punching needles through nut punching bars

A remanufacturing and bolt punching technology, which is applied in the field of fastener mold manufacturing, can solve the problems of large quality differences and large fluctuations in service life, and achieve the effects of improving service life and saving high-speed steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and examples.

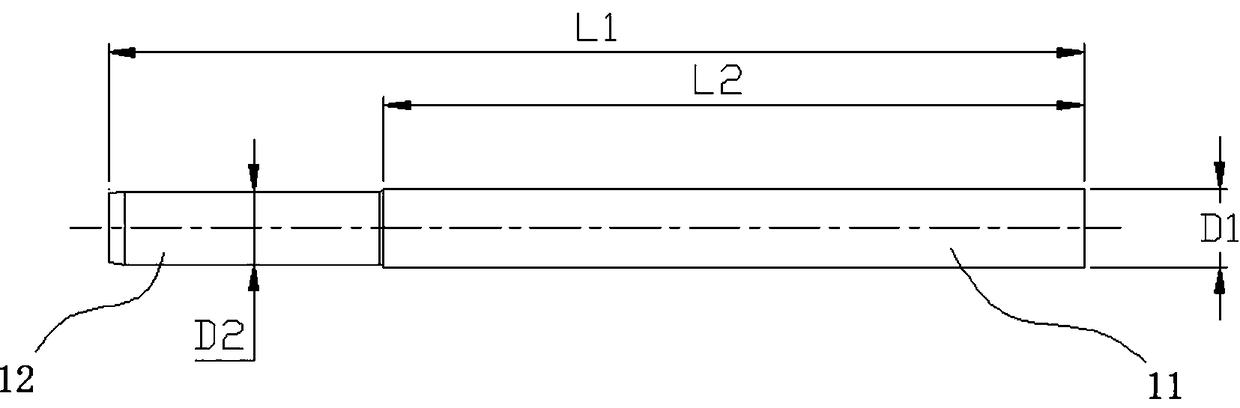

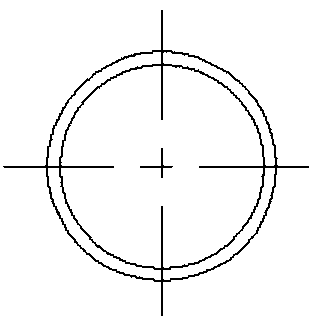

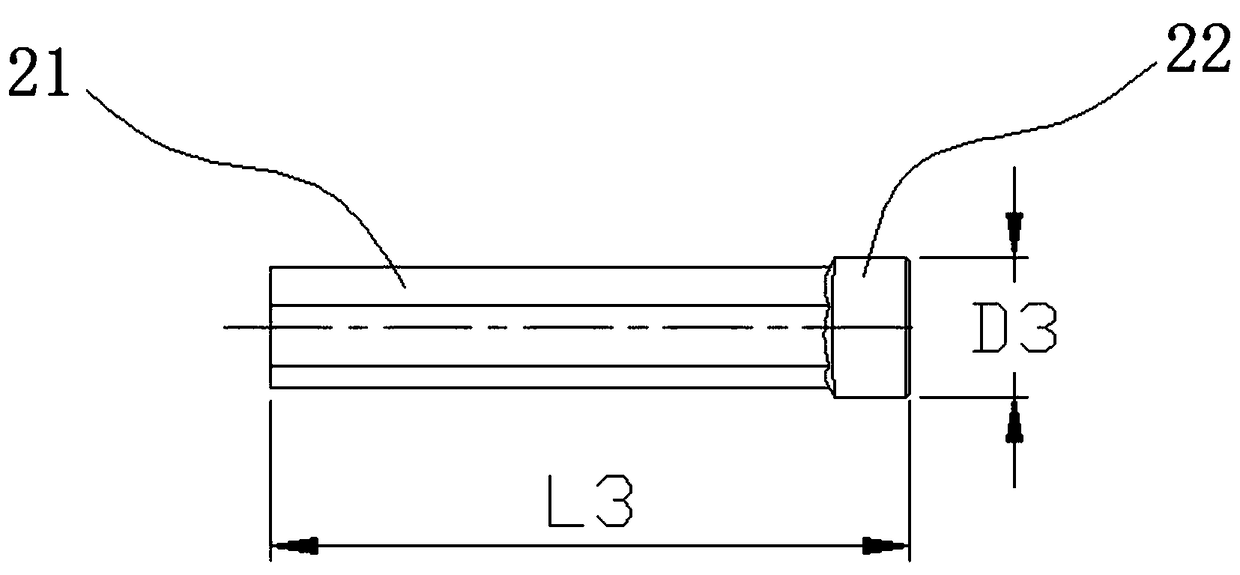

[0022] In this example, if Figure 1 to Figure 5 As shown, the remanufacturing method of nut punching rod processing bolt punching pin in the embodiment of the present invention, according to the similar working environment and force characteristics of nut punching rod and bolt punching pin, after the nut punching rod reaches the service life and wears out, According to the principle of similar size, the nut punch rod is remanufactured into the punch pin of the M6~M12 series hexagonal flange bolt.

[0023] According to the principle of similar size, the rear punch rod of the fourth sequence of the worn out nut is selected as the object of remanufacturing. The following table shows the typical remanufacturing data.

[0024] Remanufacturing object

Remanufacturing object size

remanufactured product

Product size after remanufacturing

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com