Spaceflight inertia piece double-hole feature fine grinding temperature measurement device

A grinding temperature and measuring device technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem that it is difficult to accurately infer temperature changes, etc. Achieve the effects of avoiding damage, reducing interference, and easy operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The working principle of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

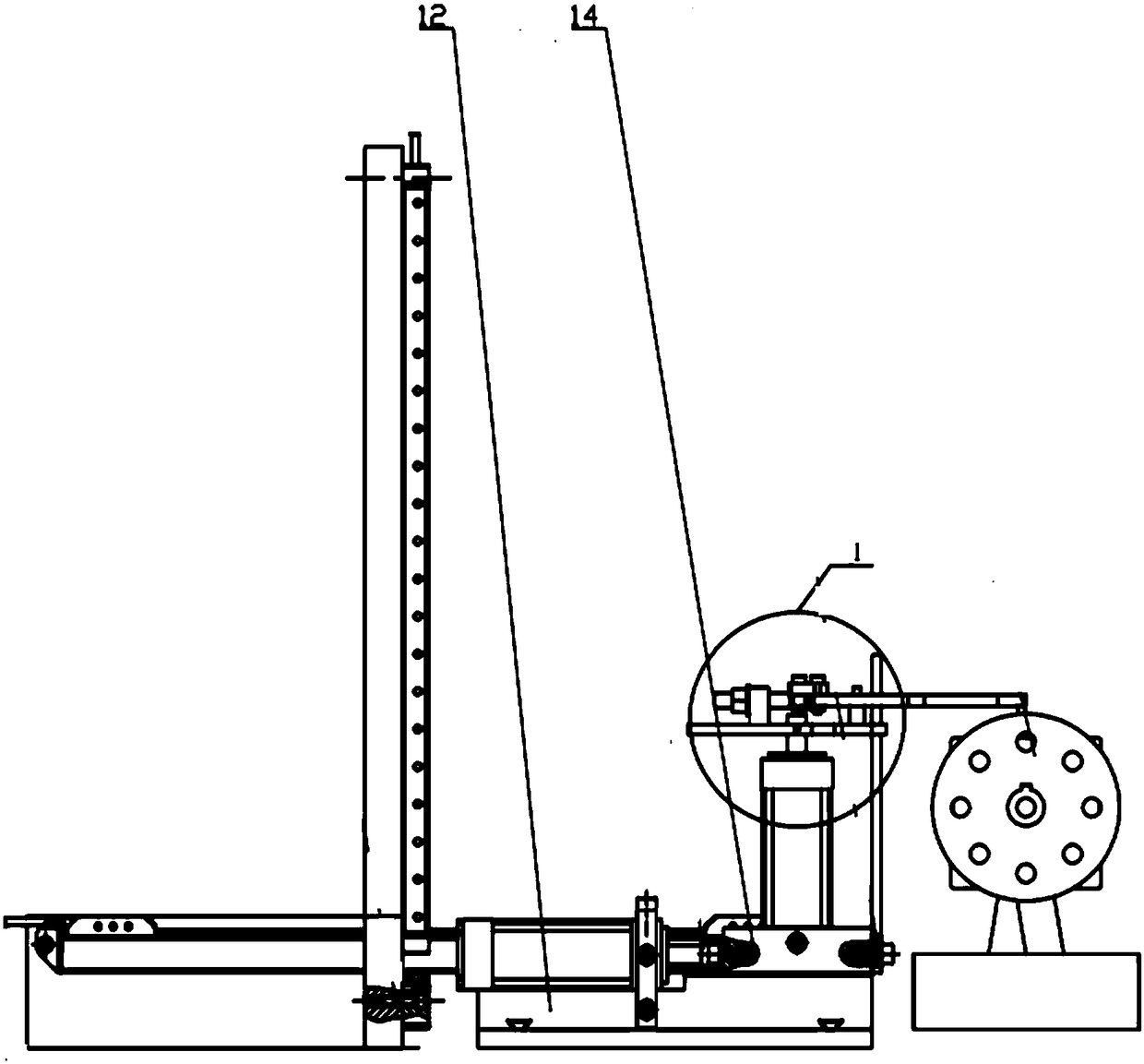

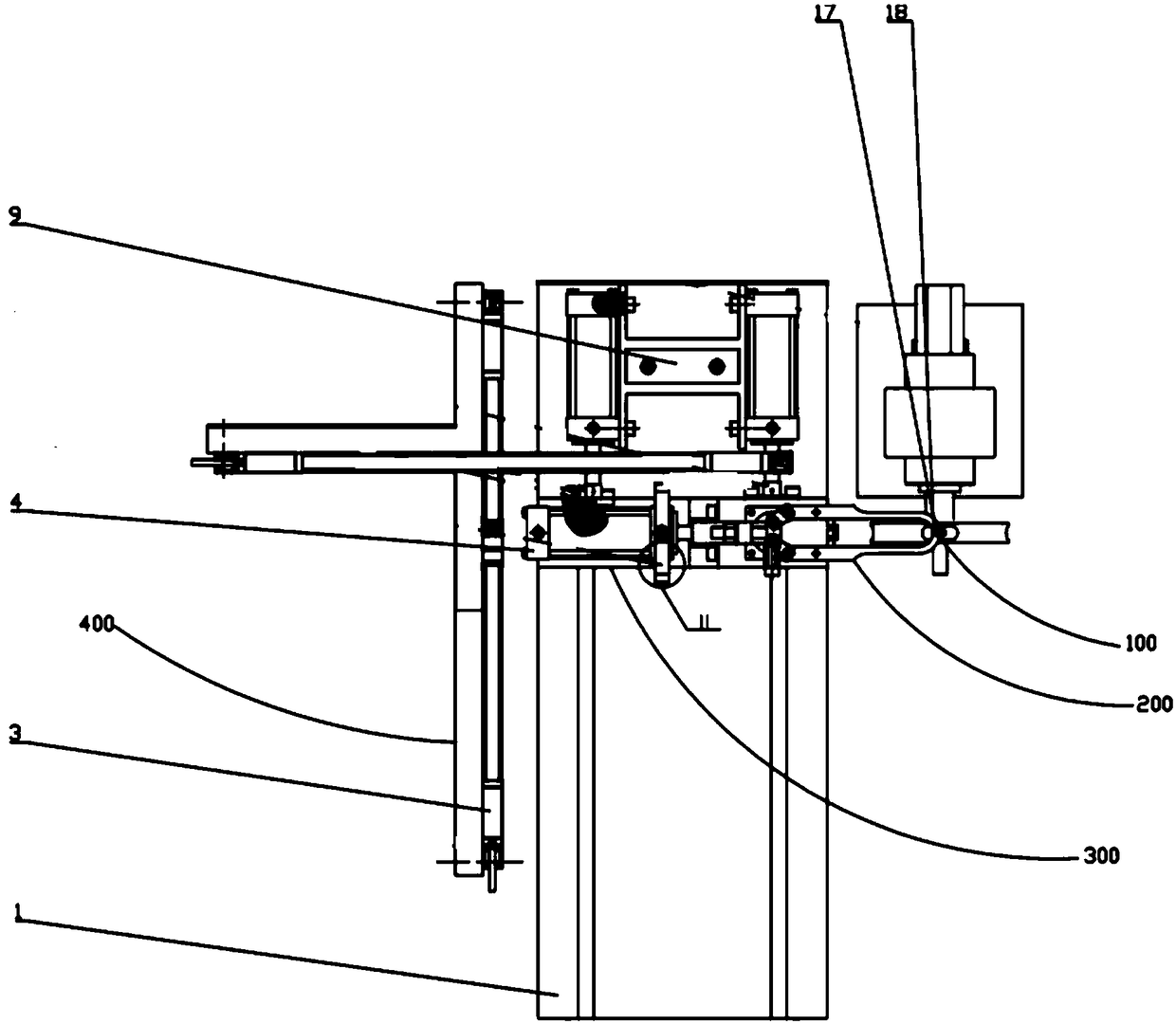

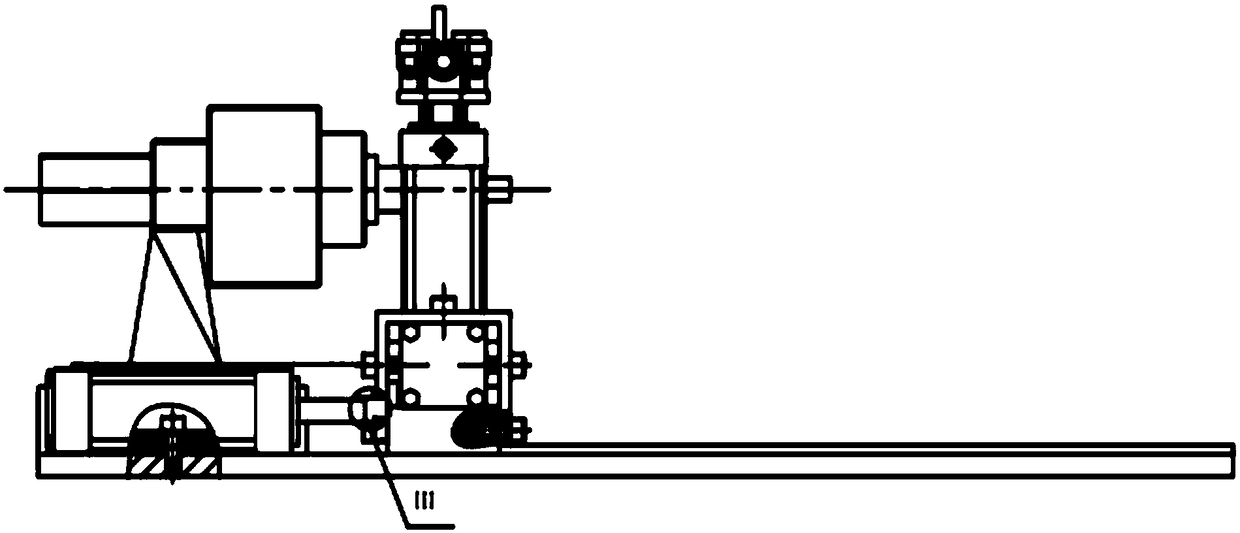

[0029] Such as Figure 1 to Figure 6 As shown, a micro-grinding temperature measurement device for aerospace inertial parts is composed of a temperature sensor 100 and an auxiliary device. The auxiliary device includes a clamping part 200, an XYZ displacement part 300, a grating and its fixing part 400.

[0030] The temperature sensor 100 is installed on the XYZ displacement part 300 through the clamping part 200, and the temperature sensor 100 is located on one side of the XYZ displacement part 300, and the other side of the XYZ displacement part 300 places the grating and its fixing part 400, and three of the gratings The grating ruler 3 is respectively placed in the directions of XYZ three axes to measure the displacement. Such as Figure 7 , as shown in 8, the temperature sensor 100 includes a bipolar thermocoup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com