Wooden product embossing device

A technology of wood products and embossing, which is applied in decorative arts, embossed ornaments, etc., can solve the problems of waste of resources, complicated structure of embossing devices, increased cost of machine use, etc., and achieve the effect of convenient embossing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

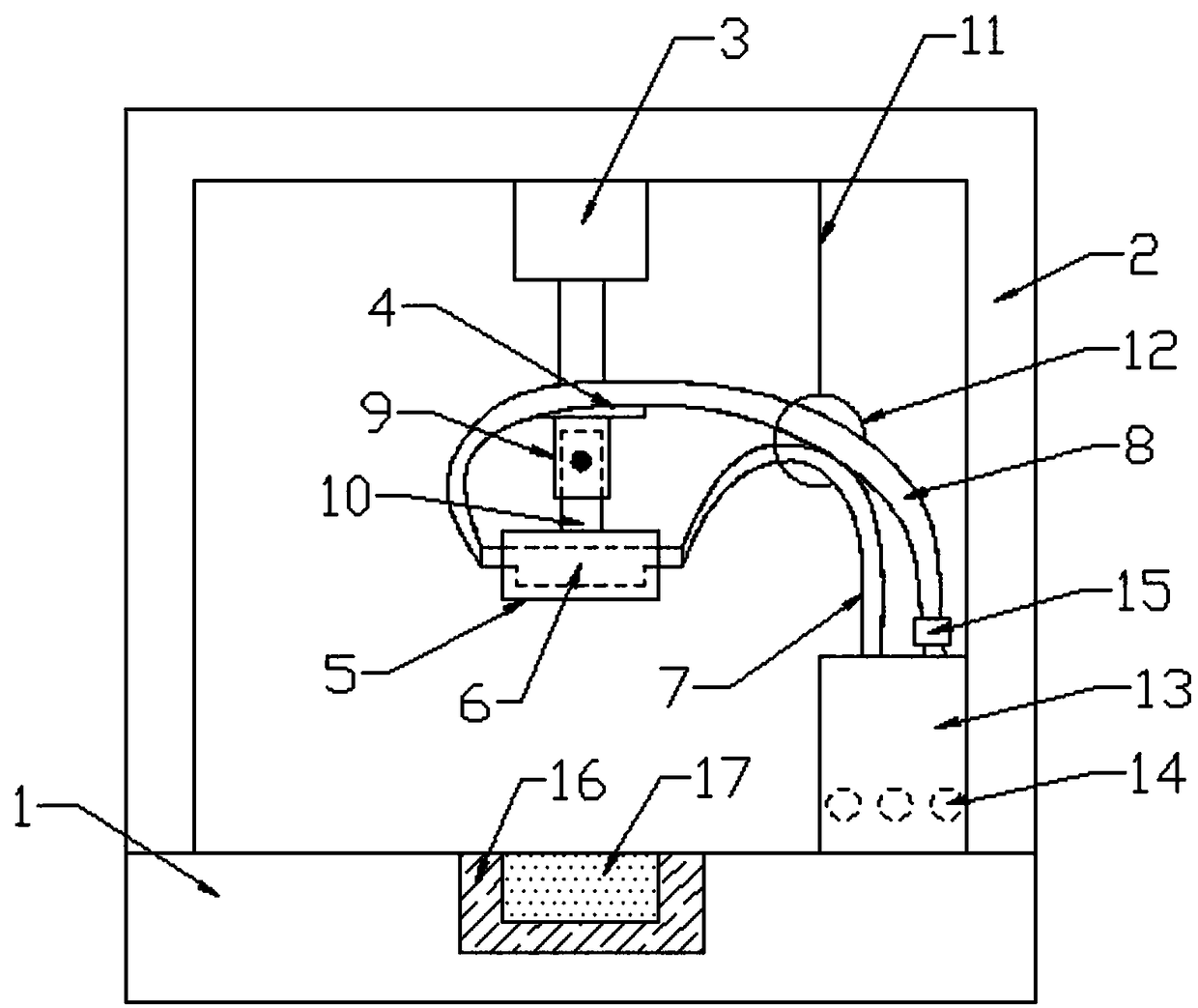

[0014] Example: such as figure 1 As shown, a wood product embossing device of the present invention includes a base 1, a support frame 2 is fixed above the base 1, a cylinder 3 is installed on the lower end surface of the top frame of the support frame 2, and the end of the piston rod of the cylinder 3 is fixed with a The fixed plate 4, the lower end surface of the fixed plate 4 is provided with a connecting pipe 9, the connecting pipe 9 is connected with a connector 10, the bottom end of the connector 10 is fixed on the top of the embossing die 5, so that the fixed plate 4 can be driven by the cylinder 3 rise or fall, and then make the fixed plate 4 drive the connecting pipe 9 to rise or fall, and then drive the embossing die 5 to rise or fall, so that the embossing die 5 can emboss the wooden product 17; The oil chamber 6 and the oil inlet of the oil storage chamber 6 are connected to the oil outlet of the heat transfer oil tank 13 through the oil inlet pipe 8, and the oil o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com