Asphalt heating heat exchanger

A technology of heat exchanger and heater, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, heating processing of tar pitch/petroleum pitch/natural pitch, petroleum industry, etc., which can solve the problem of slow heating speed and low heating efficiency , Inconvenient asphalt temperature and other problems, to achieve the effect of increasing speed and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

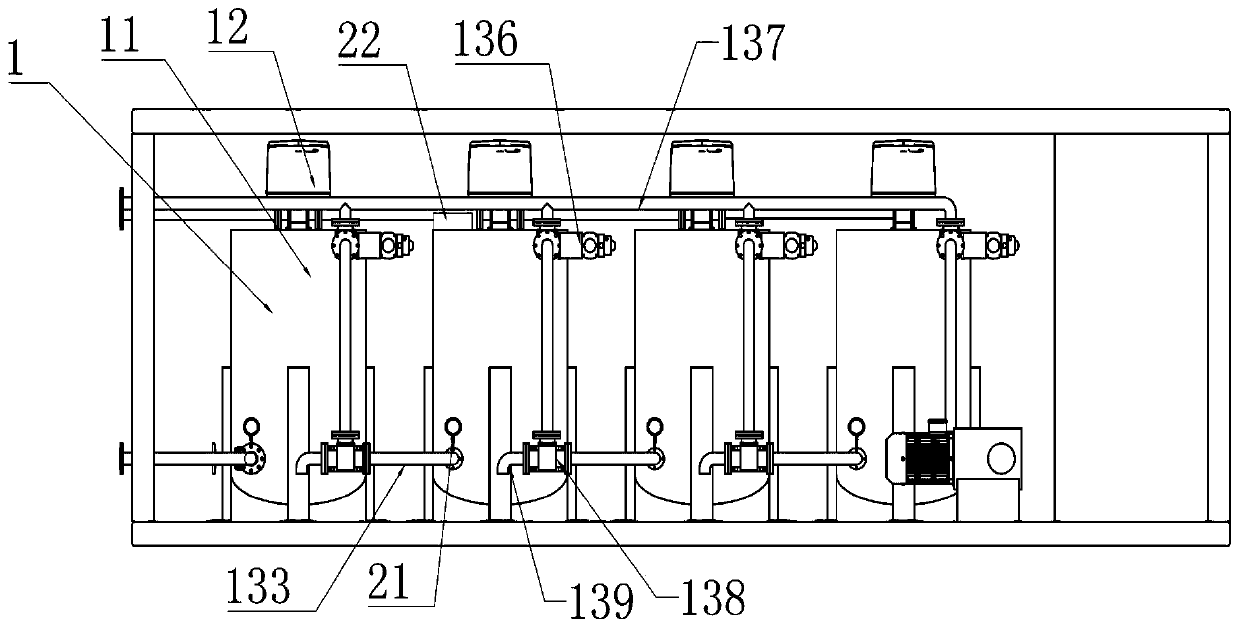

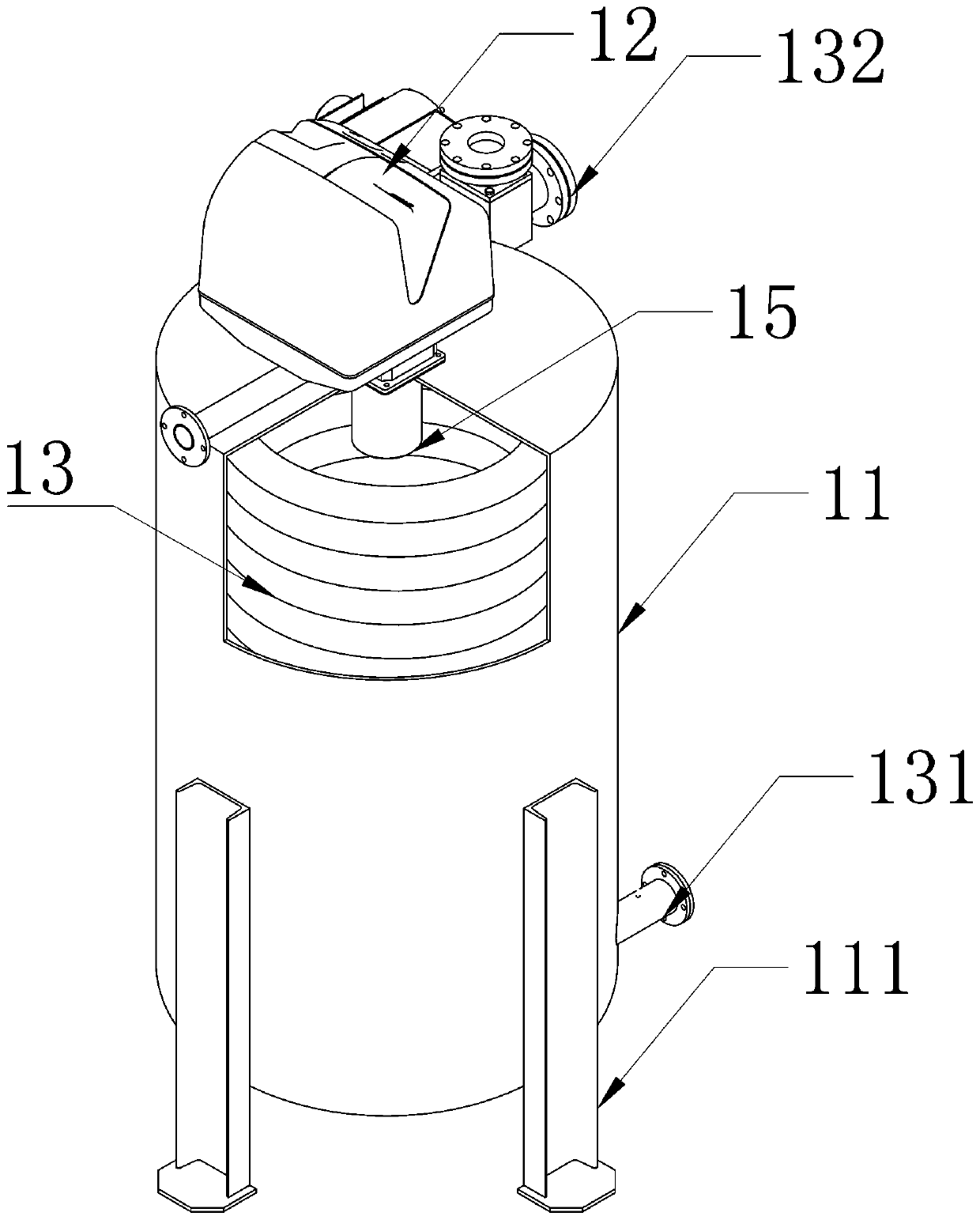

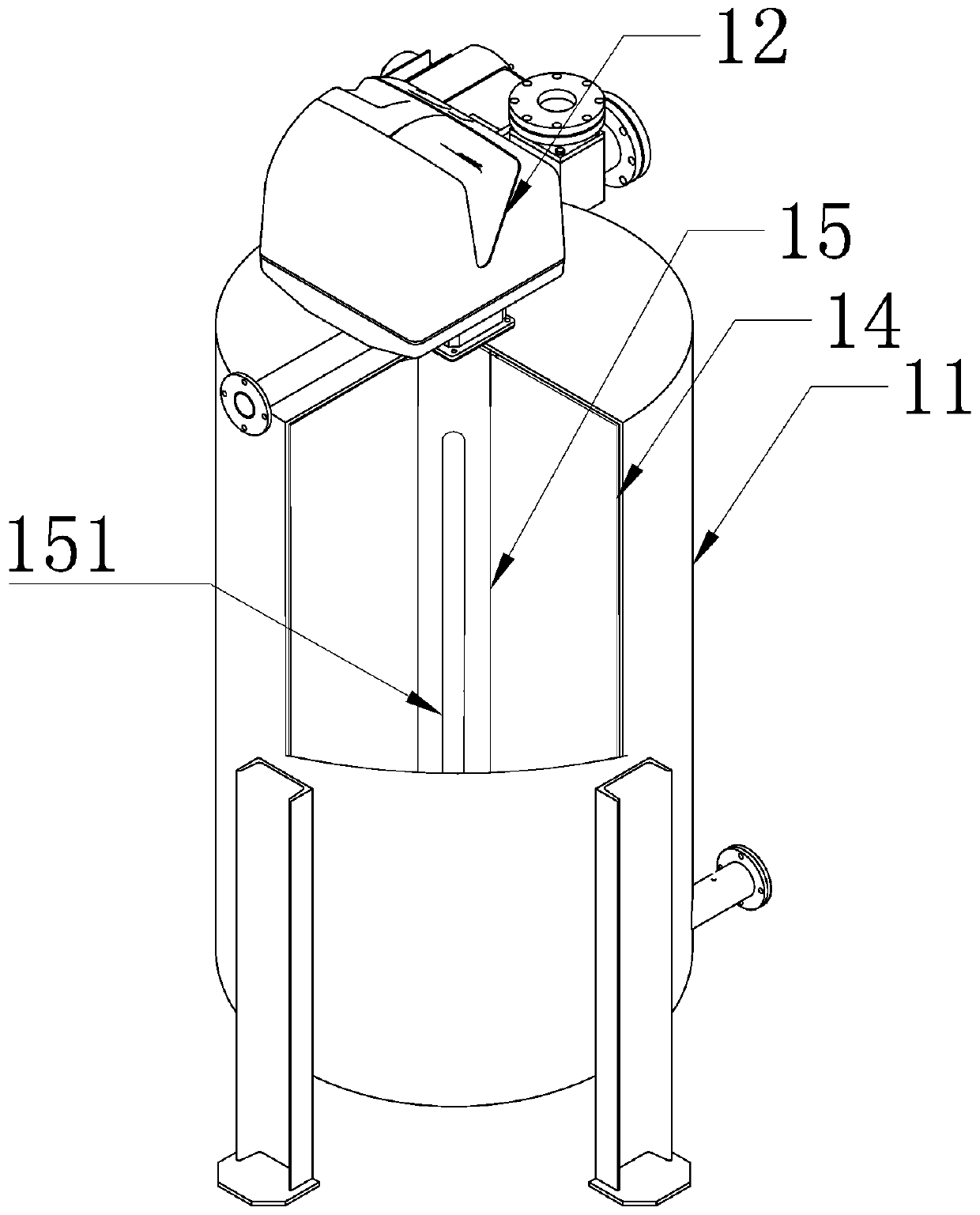

[0027] Such as Figure 1 ~ Figure 3 As shown, the asphalt heating heat exchanger includes a plurality of sequentially connected heating devices 1 and a temperature control device arranged between two adjacent heating devices 1; the heating device 1 includes a tank body 11, a heater 12 and a The asphalt pipeline 13 for transporting asphalt; the inside of the tank 11 is hollow and covered with an insulating layer 14 on the tank wall; the heater 12 is fixed on the top of the tank 11, and the heating body 15 of the heater 12 is located in the tank The middle part of the body 11; the asphalt pipeline 13 is located inside the tank body 11, and the asphalt pipeline 13 is a spiral coil structure; the inlet 131 at the lower end of the asphalt pipeline 13 and the outlet 132 at the upper end both pass through the tank body 11 to the outside, And the inlet 131 and the outlet 132 are all fixed with the tank body 11; the adjacent two heating devices 1, wherein, the outlet 132 of the asphalt...

Embodiment 2

[0037] Such as Figure 4 As shown, on the basis of Embodiment 1, the asphalt pipeline 13 can also be a plurality of standpipes 16 arranged vertically and equidistantly along the circumferential direction of the tank body 11, and the upper and lower ends of the standpipes 16 extend To the outside of the tank body 11, and the end of the standpipe 16 is connected into a pipeline by means of an elbow 17, and the elbow 17 and the standpipe 16 are fixed by means of a detachable connection structure; The first flange 161 and the second flange 171 fixed on the riser 16; the first flange 161 and the second flange 171 are connected by bolts.

[0038] The asphalt pipeline 13 can also be a plurality of standpipes 16 arranged vertically and equidistantly along the circumferential direction of the tank body 11, and the ends of the standpipes 16 are connected into a pipeline with a detachable connection structure by means of an elbow 17. On the basis that the asphalt in the asphalt pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com