Oxidation combined wastewater treatment system

A wastewater treatment system, ozone technology, applied in the direction of oxidized water/sewage treatment, special compound water treatment, multi-stage water treatment, etc., can solve the problems of expensive equipment construction costs and limited practical application, so as to reduce production and operation costs and save Effect of water use and improvement of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

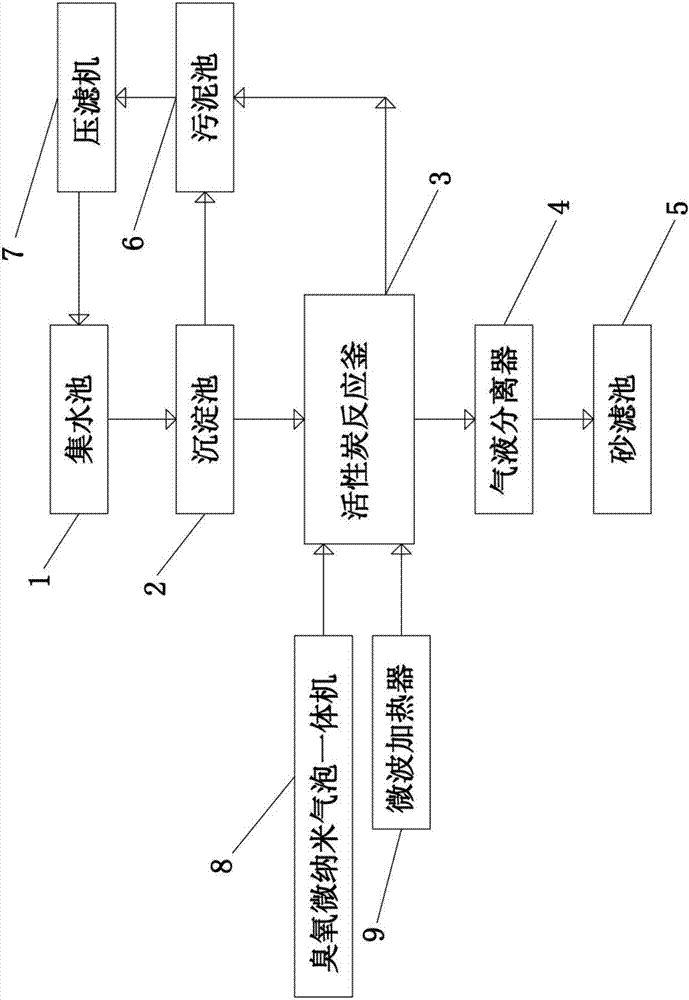

[0019] Combine below figure 1 The present invention is further described with specific embodiment:

[0020] The waste water treatment system of combined oxidation disclosed by the present invention comprises an activated carbon reactor 3, which is correspondingly connected to the sedimentation tank 2, and the sedimentation tank 2 is correspondingly connected to the sump 1, and in the activated carbon reactor 3 An ozone micro-nano bubble integrated machine 8 is provided, and the ozone micro-nano bubble integrated machine 8 is provided with a gas source inlet valve, and the gas source is one of an air source and an oxygen source. The micro-nano bubble integrated machine 8 in the combined oxidation wastewater treatment system of the present invention includes a micro-nano bubble generator and an ozone generator device. The ozone generator device provides ozone gas with a relatively high concentration, and then the ozone gas is passed into the micro-nano bubble generating device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com