Electromagnetic induction coil for magnetic particle uniform heating

An electromagnetic induction coil and magnetic particle technology, which is applied in the field of electromagnetic induction coils where magnetic particles are uniformly heated, can solve problems such as low efficiency, achieve high heating efficiency, fully utilize heat, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

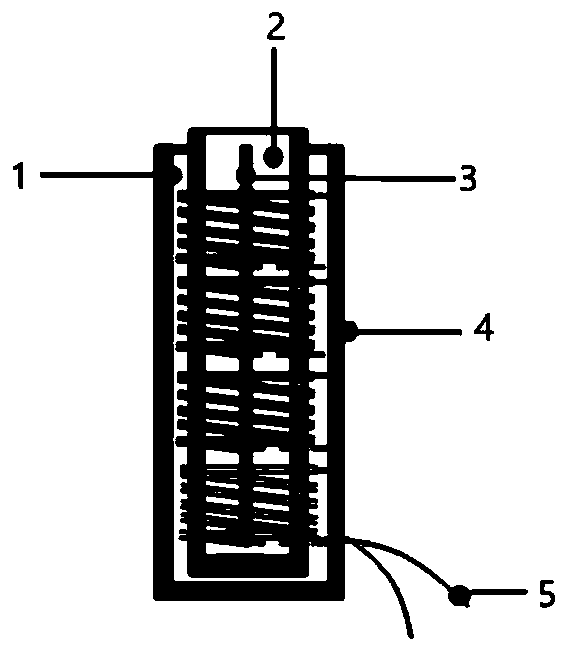

[0064] Embodiment 1: electromagnetic induction coil of the present invention

[0065] The implementation mode of this embodiment is as follows:

[0066] A cylindrical heating chamber 2 is set in the center of the magnetic particle uniform heating, and a heat insulating protective layer 4 is arranged outside the heating chamber 2; a ceramic magnetic permeable groove 1 is installed between the heating chamber 2 and the heat insulating protective layer 4, and the ceramic magnetic permeable groove 1 Place the electromagnetic induction coil 5 in it. The electromagnetic induction coil 5 is composed of 3 close-wound coils with a skeleton, and these coils are made of circular copper wires with a resistivity of 1.6×10 -8 Ω·m. These coils are connected in parallel through a touch switch sold under the trade name DSIC05LSGET type switch by Dongguan Xindu Electronics Co., Ltd. and an N-channel TrenchMOS ultra low level FET component sold under the trade name PH2925U type by Nexperia Sem...

Embodiment 2

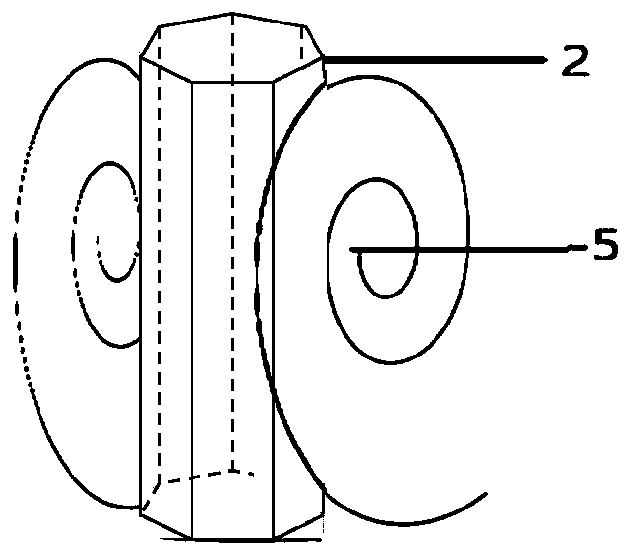

[0069] Embodiment 2: electromagnetic induction coil of the present invention

[0070] The implementation mode of this embodiment is as follows:

[0071] A hexagonal heating chamber 2 is set in the center of the magnetic particle uniform heating, and a heat insulating protective layer 4 is arranged outside the hexagonal heating chamber 2; a ceramic magnetic conduction groove 1 is installed between the hexagonal heating chamber 2 and the heat insulating protective layer 4 A planar electromagnetic induction coil 5 is placed in the ceramic magnetic permeable slot 1 . The planar electromagnetic induction coil 5 is placed on the side wall of the polygonal heating chamber 2. The planar electromagnetic induction coil 5 is composed of 4 closely wound coils with skeletons. These coils are made of iron wires with a rectangular cross section, and their resistivity is 1.65. ×10 -8 Ω·m,

[0072] These coils are connected in series through a push-type switch sold by Dongguan Yuanteng Elec...

Embodiment 3

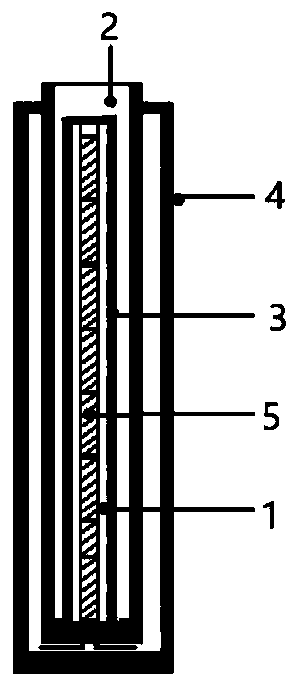

[0075] Embodiment 3: electromagnetic induction coil of the present invention

[0076] The implementation mode of this embodiment is as follows:

[0077] A cylindrical heating chamber 2 is arranged at the center of the magnetic particle soaking, and a heat insulating protective layer 4 is arranged outside the cylindrical heating chamber 2; a ceramic magnetic conduction groove 1 is arranged at the bottom of the cylindrical heating chamber 2, and the ceramic magnetic conduction groove 1 is placed Electromagnetic induction coil 5. The electromagnetic induction coil 5 is composed of a close-wound coil with a skeleton, which is made of stainless iron wire with a triangular cross-section, and its resistivity is 1.63×10 -8 Ω·m, and the coil passes through the touch switch sold by Dongguan SanDisk Electronic Technology Co., Ltd. under the trade name micro switch button and the medium and high coil sold and composed of STMicroelectronics Co., Ltd. Frequency oscillation circuit connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com