Self-driven repetitive locking and releasing mechanism with honeycomb structure and its 4D printing preparation method and locking and releasing method

A technology for repeatedly locking and releasing mechanisms, which is applied to space navigation equipment, 3D object support structures, motor vehicles, etc., can solve problems such as large mass of nearby devices and explosive bolts, explosion fragments or gas damage, and huge impact, etc., to achieve Superior deformation repeatability, no pollution strength, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

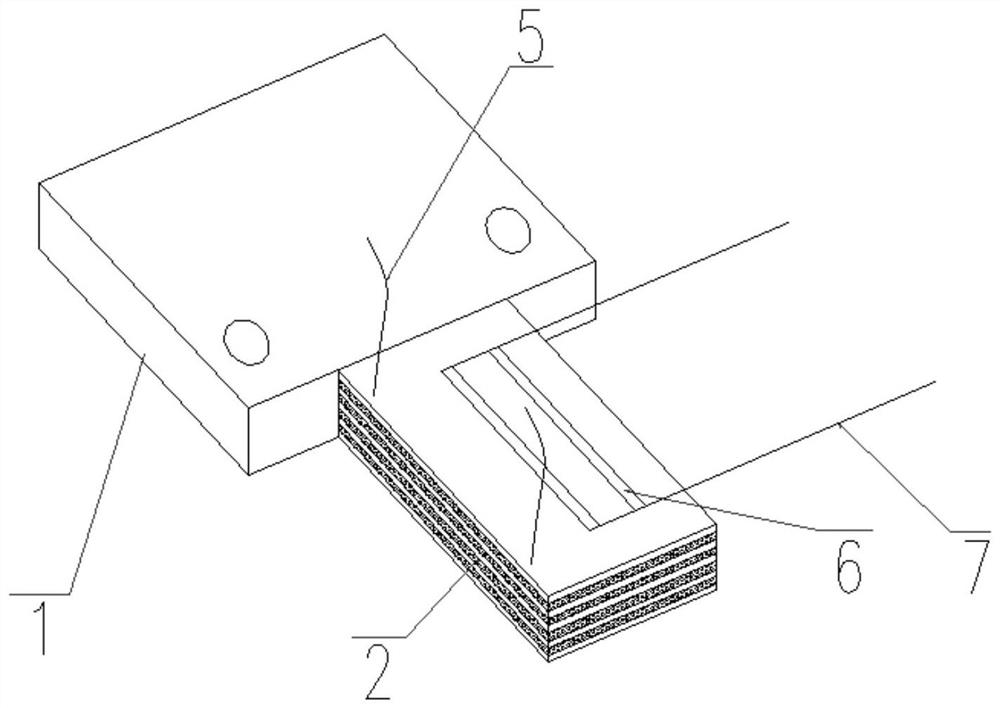

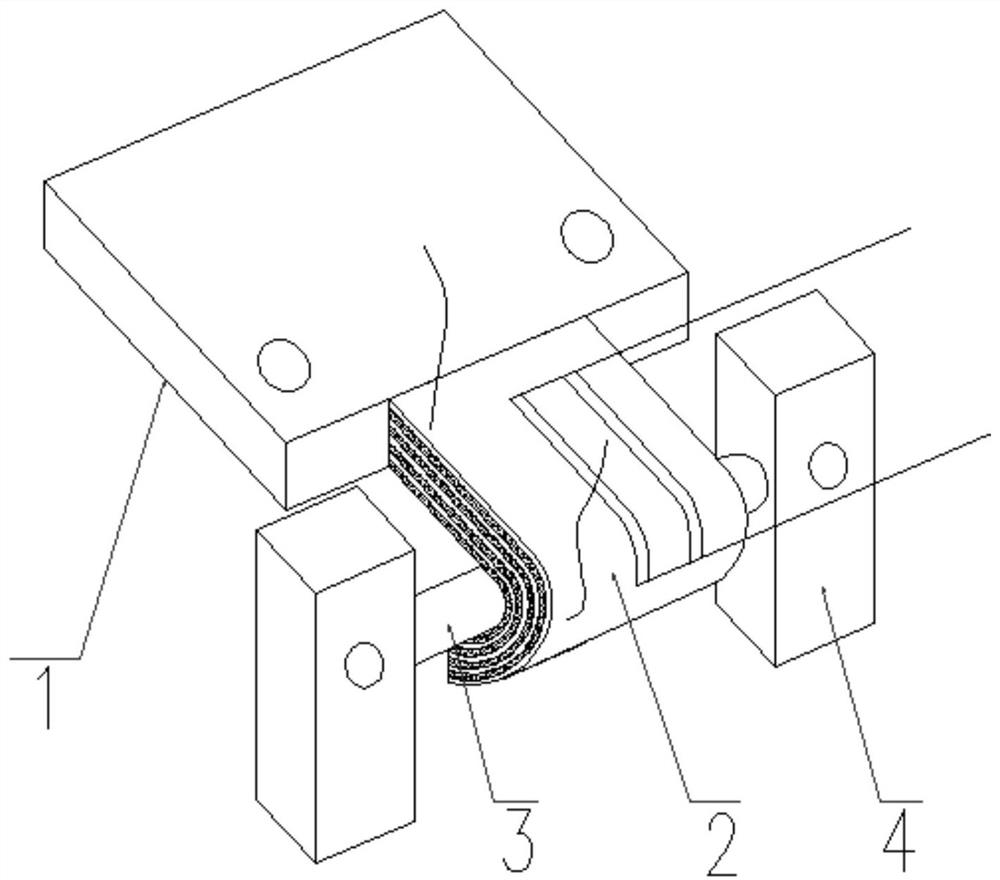

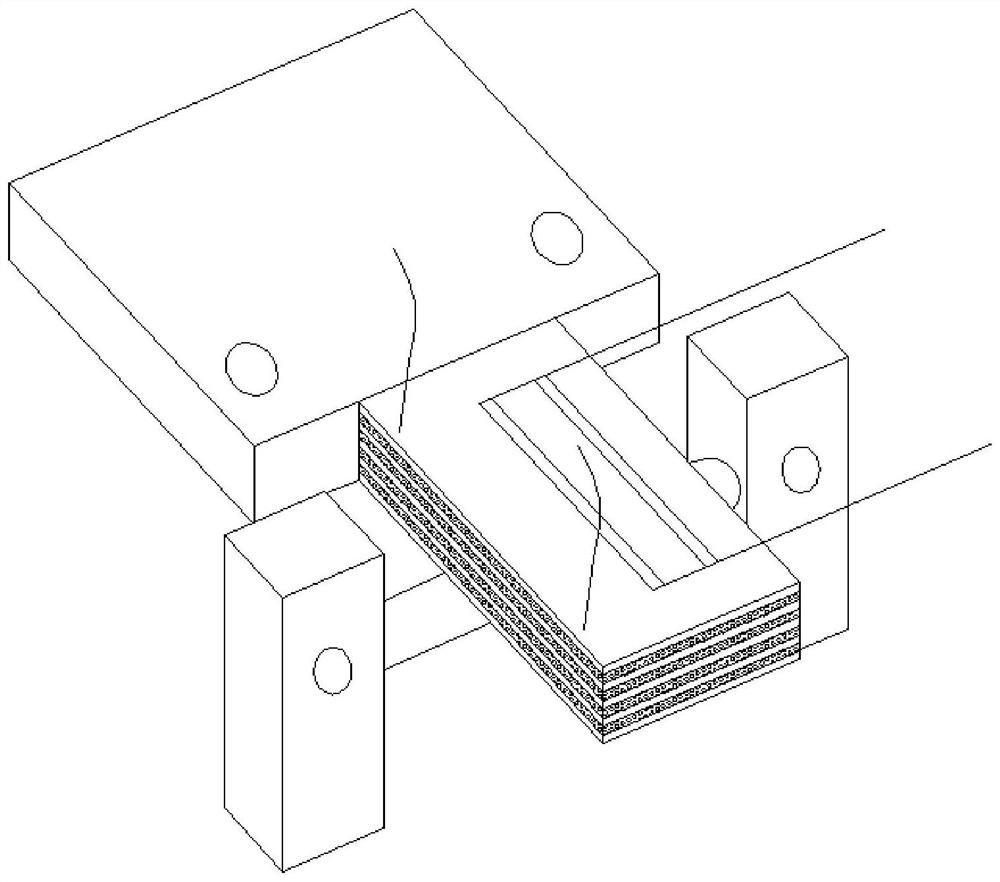

[0040] Specific implementation mode one: combine Figure 1~4 Describe this embodiment, the self-driven repeated locking release mechanism with honeycomb structure in this embodiment is composed of a locking member and a connecting member; the locking member is composed of a locking member base 1 and a deformation rod 2; the connecting member is composed of a connecting rod 3 and Connecting rod fixed block 4 forms;

[0041]One end of the deformation rod 2 is affixed to the base of the locking member 1, and several through holes are arranged on the base of the locking member 1; the main body of the deformation rod 2 is composed of several plane layers and several honeycomb layers, and the honeycomb layer is arranged on the adjacent between plane layers;

[0042] The main material of the planar layer and the honeycomb layer of the deformation rod 2 is a shape memory polymer, and a fiber reinforced phase is arranged in the shape memory polymer, and two wires 5 are arranged on the...

specific Embodiment approach 2

[0050] Embodiment 2: This embodiment differs from Embodiment 1 in that: the connecting rod 3 and the connecting rod fixing block 4 are made of aluminum alloy or titanium alloy. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0051] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the honeycomb unit in the honeycomb layer is a hexagonal prism, the cross section of the hexagonal prism is hexagonal, and the side length of the hexagon is 0.25-0.35 mm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com