A kind of foam glass-ceramics and preparation method of composite utilization of iron tailings and waste glass

A technology of foamed glass-ceramics and waste glass, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., and can solve the problems of high equipment requirements, high matching degree of foaming agent and powder vitrification temperature, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

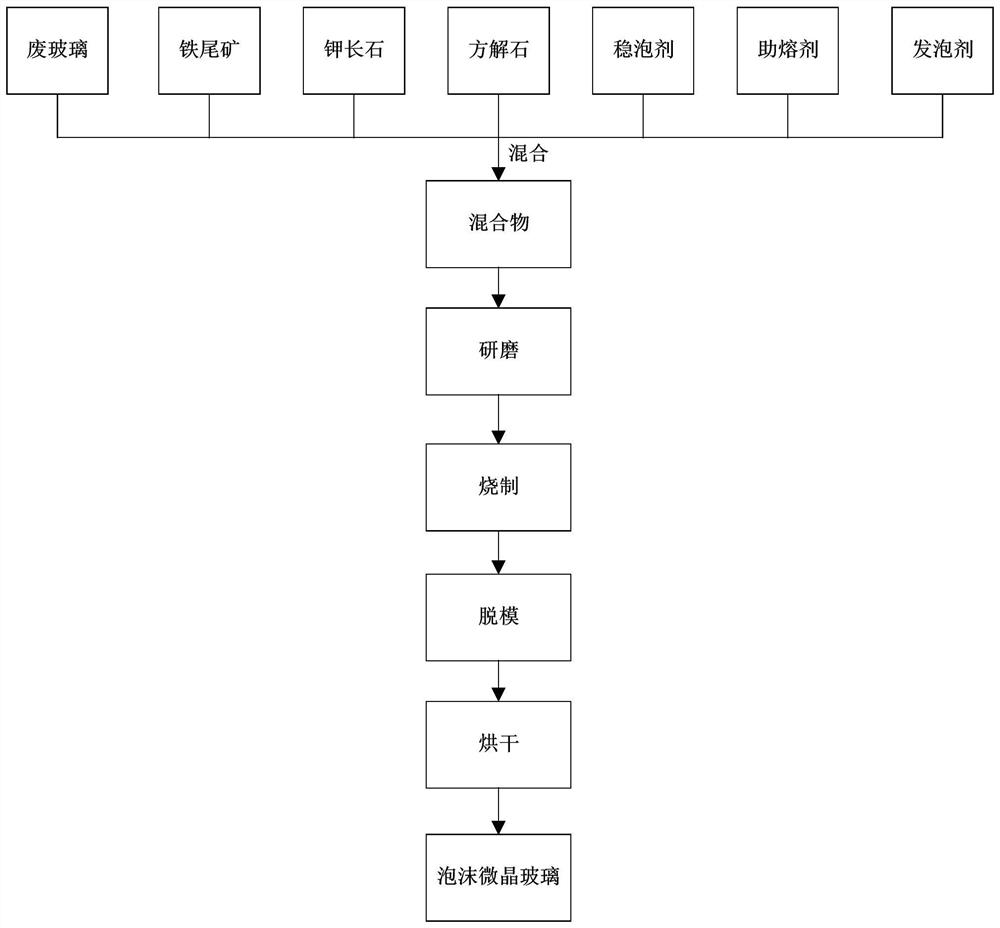

[0034] refer to figure 1 and figure 2 , the embodiment of the present invention also provides the preparation method of the foamed glass-ceramic of above-mentioned composite utilization iron tailings and waste glass, comprises the following steps:

[0035] Step S1, weighing 32% to 37% of waste glass, 26% to 31% of iron tailings, 20% to 25% of potassium feldspar, 2% to 5% of calcite, and 0.8% to 1.5% of foam stabilizer in terms of mass percentage Agent, 2% to 4% flux and 0% to 7% foaming agent are mixed to obtain a mixture; among them, the waste glass is waste flat glass, and the foam stabilizer is Na 3 PO 4 12H 2 O, co-solvent selection B 2 o 3 , the foaming agent is green α-SiC;

[0036] Step S2, grinding the mixture so that the particle size reaches below 200 mesh, then adding the ground mixture into a mold covered with release paper, paving and compacting;

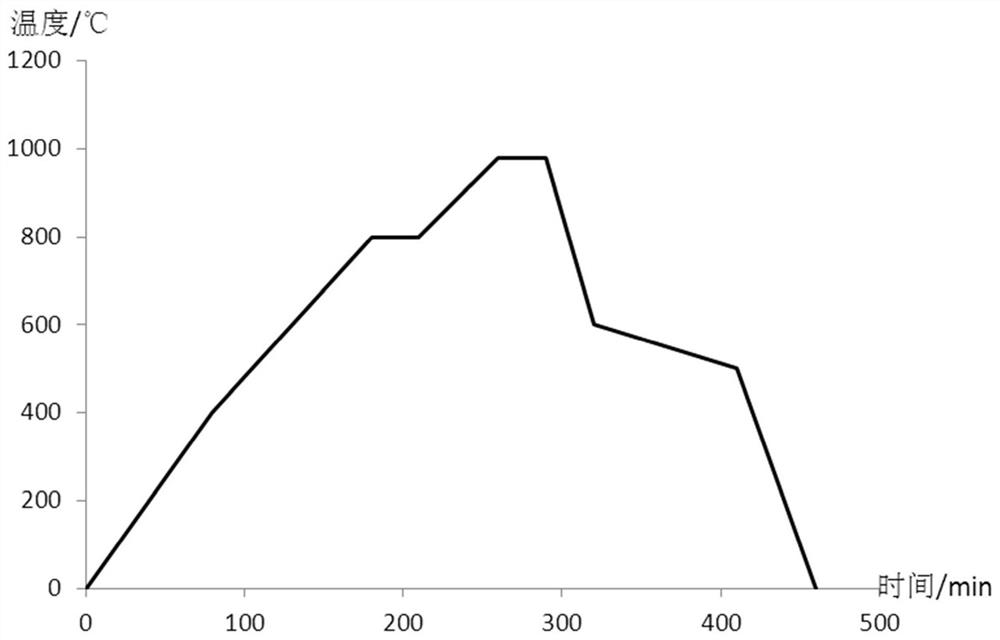

[0037] Step S3, put the mold and the mixture into a muffle furnace for firing, first rapidly raise the temper...

Embodiment 1

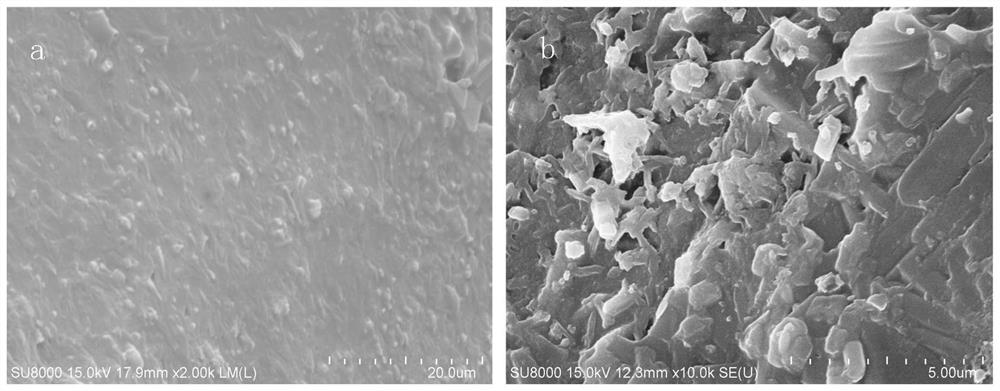

[0040]In terms of mass percentage, weigh 35.698% waste glass, 28.627% iron tailings, 22.957% potassium feldspar, 3.763% calcite, 0.953% Na 3 PO 4 12H 2 O, 3.002% B 2 o 3 Mix with 5% green α-SiC to obtain a mixture; add the mixture to a vibrating mill and grind for 3 minutes at a rate of 710 rad / min to make the particle size of the mixture below 200 mesh, then weigh the ground mixture and add it to the In the corundum mold of alumina release paper, pave and compact; put the corundum mold and the mixture into the silicon-molybdenum rod high-temperature muffle furnace, first rapidly raise the temperature to 880°C, keep warm for 30min, and then heat up to 1060°C After foaming for 10 minutes, quickly cool down to 600°C to start annealing, then slowly cool down at a rate of 100°C / h, and after two hours, the temperature drops from 600°C to 400°C to complete the annealing process, then stop heating, and cool down with the furnace to Room temperature, demoulding treatment, using a ...

Embodiment 2

[0049] The only difference between Example 2 and Example 1 is that the foaming temperatures are respectively set to 1040°C, 1050°C, 1070°C, and 1080°C, and the rest are basically the same as Example 1.

[0050] The flexural properties (bending strength) and density data of the foamed glass-ceramics prepared under different foaming temperatures are shown in Table 1:

[0051] The flexural properties (flexural strength) and density data of the foamed glass-ceramics prepared under different foaming temperatures in table 1

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com