Graphite tailing concrete mixture and preparation method thereof

A technology of graphite tailings and admixture, which is applied in the field of building materials, can solve the problems of graphite tailings polluting the environment, lack of construction sand, etc., and achieve high strength and reduce the effect of construction sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

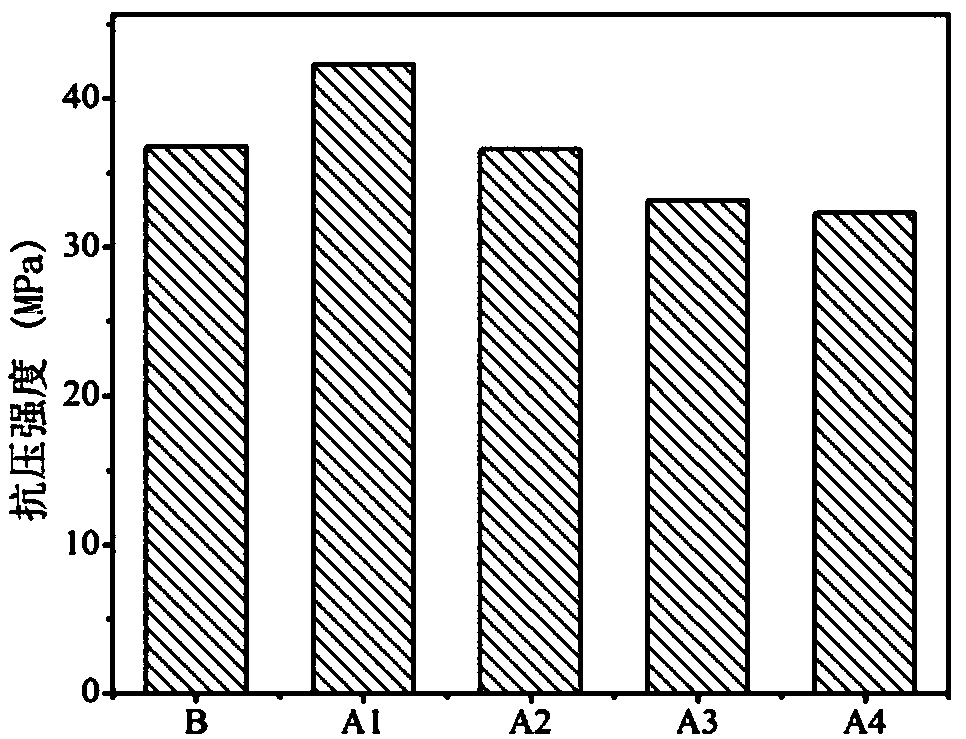

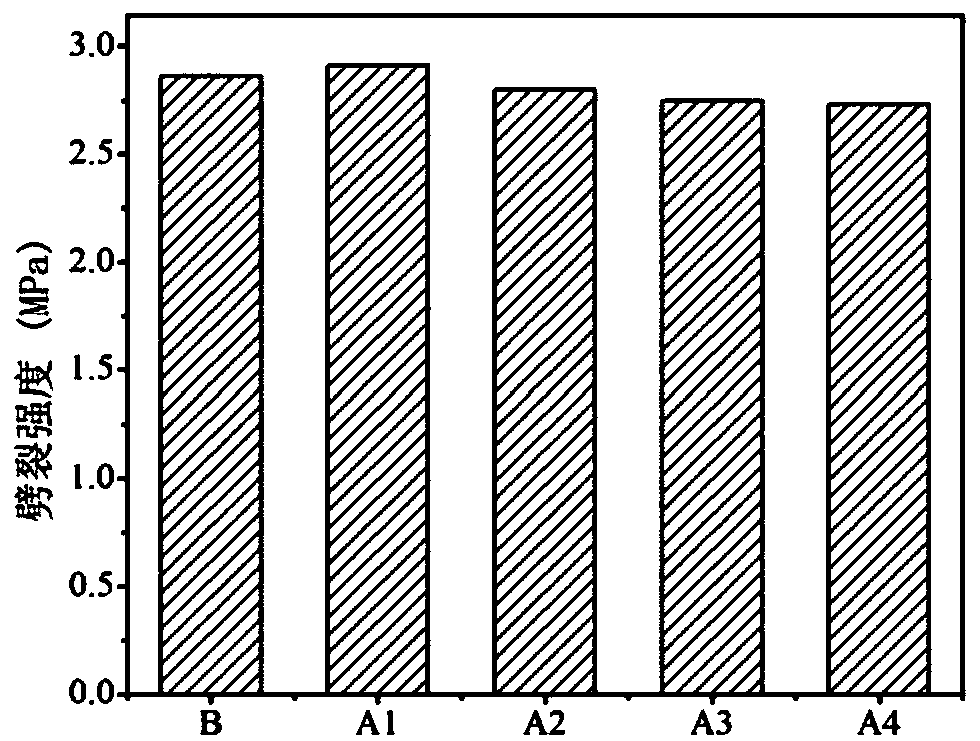

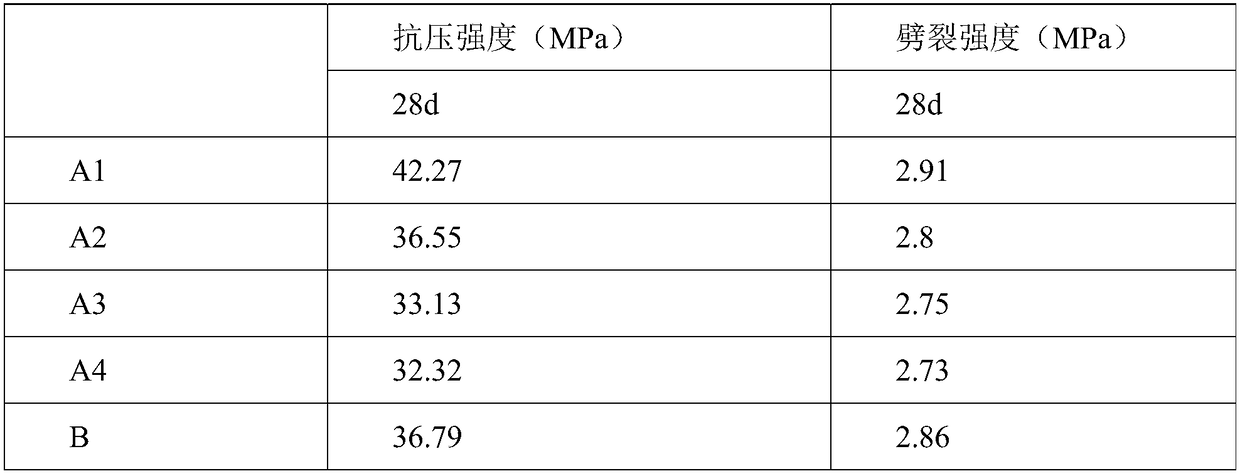

[0021] Embodiment 1: The graphite tailings concrete mixture described in this embodiment, the mixture is composed of 346.15 parts of cement, 1284.1 parts of stones, 330.20-550.33 parts of sand, and 59.97-239.88 parts of graphite tailings in parts by weight. It is made of ore, 1-1.3 parts of water reducing agent and 180 parts of water. See Table 1 for details.

[0022] Table 1 Concrete mix ratio by weight parts

[0023] Tailings Dosage

sand

pebbles

water

tailings

0

346.15

550.33

1284.10

180.00

0.00

1.0

10%

346.15

495.30

1284.10

180.00

59.97

1.0

20%

346.15

440.26

1284.10

180.00

119.94

1.0

30%

346.15

385.23

1284.10

180.00

179.91

1.3

40%

346.15

330.20

1284.10

180.00

239.88

1.3

[0024] In this embodiment, the waste solid material produced in the graphite mining process-graphite tailings is added to th...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in this embodiment, in order to optimally improve the strength of graphite tailings concrete, the particle size of the stone is 5-40.5 mm, and the particle size of the sand is 0.16 mm. ~5mm (medium sand), the particle size of graphite tailings is 0.2~0.4mm.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in this embodiment, the water reducer is a naphthalene-based high-efficiency water reducer. The water reducer can be a naphthalene-based high-efficiency water-reducer, a polycyclic aromatic salt-type water-reducer, or a polycarboxylate water-reducer. In order to reduce costs, the water-reducer in this embodiment is a naphthalene-based high-efficiency water reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com