Preparation method for 3D-printed conductive hydrogel

A conductive hydrogel, 3D printing technology, applied in the field of electrohydrogel, can solve the problem that conductive hydrogel cannot be printed, and achieve the effect of saving material application, simple process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

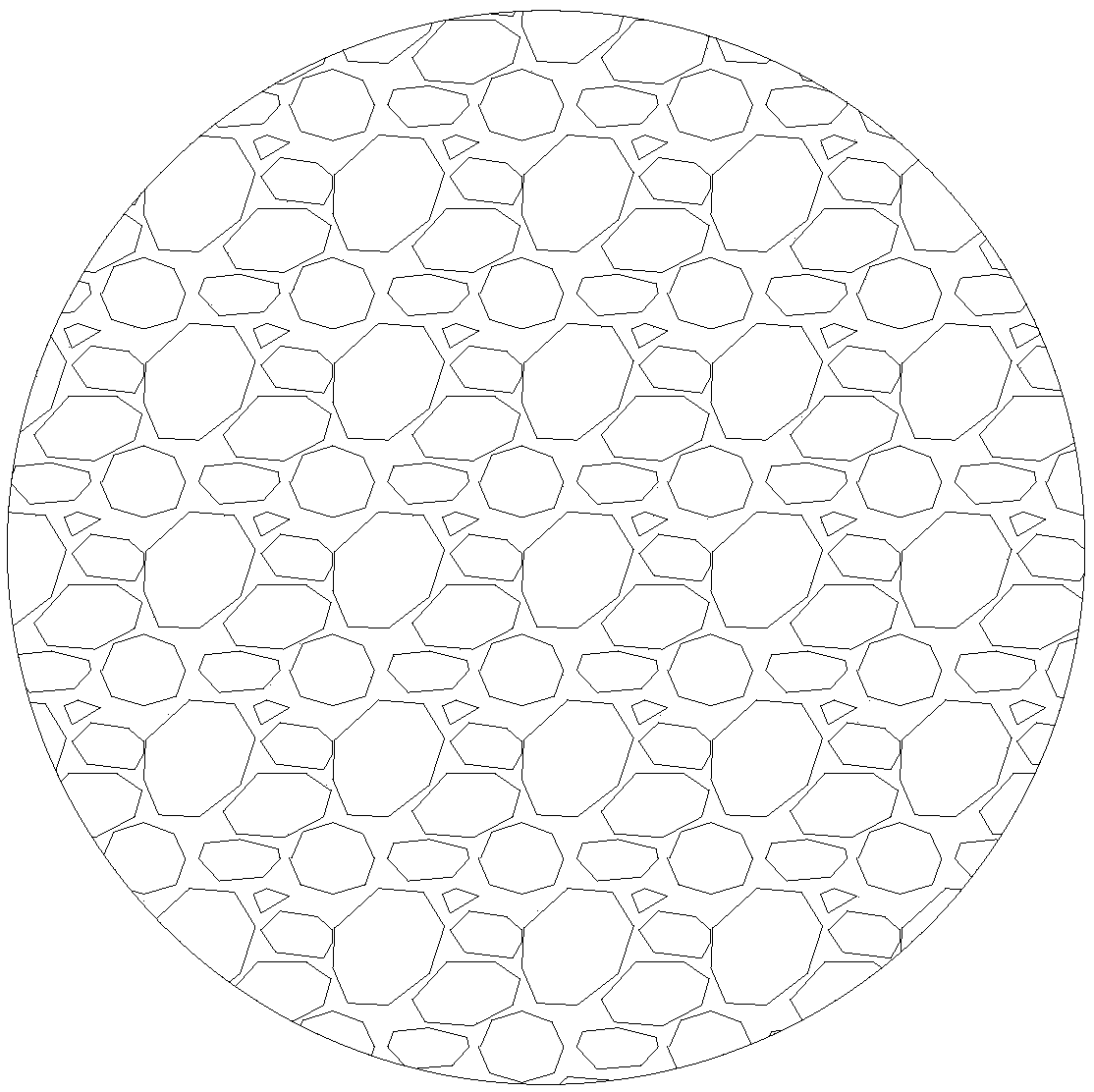

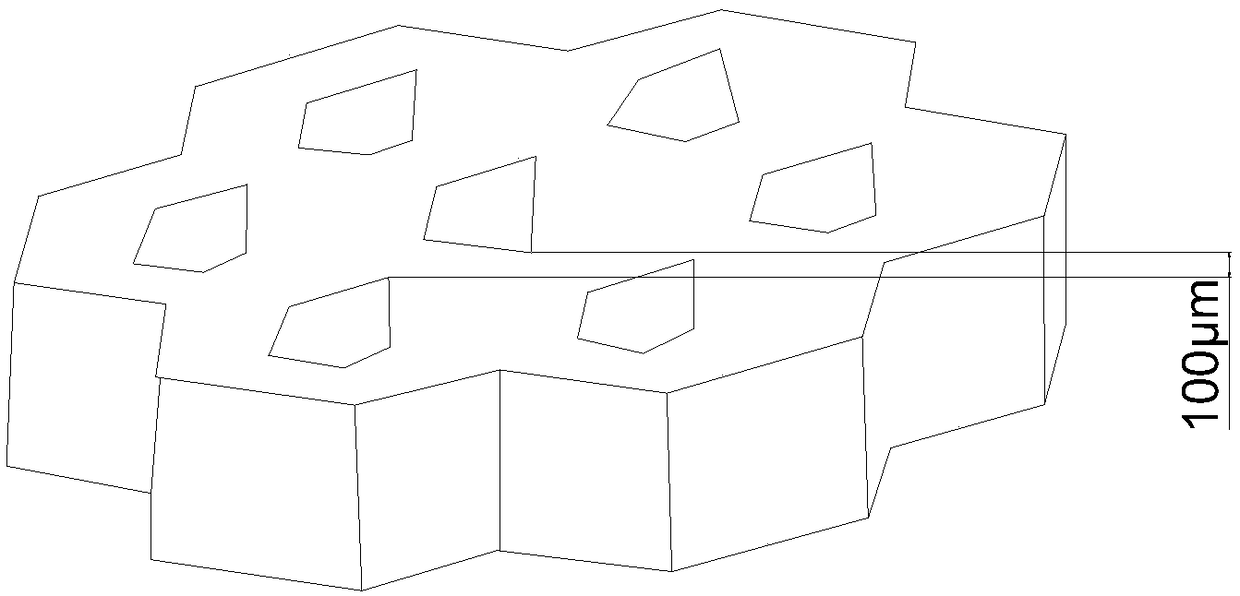

[0025] Such as figure 1 and figure 2 Shown, a kind of preparation method of 3D printing conductive hydrogel comprises the following steps:

[0026] S1. Take 30% PEGDA with a molecular weight of 700 Daltons and 70% water to form a mixture, add 2phr photoinitiator and 0.2phr dye, and mix uniformly to obtain a photocurable resin;

[0027] S2. Use Solidworks to design the three-dimensional digital model of the honeycomb structure and convert it into an STL file format. Use the prepared value to print the designed three-dimensional digital model on a DLP 3D printer to obtain a three-dimensional support structure of polyethylene glycol diacrylate. It has a plurality of irregular pores, the spacing between the pores is greater than 100 μm;

[0028] S3. Wash the printed structure with water to remove the uncured resin on the surface, and dry it;

[0029] S4, the polyethylene glycol diacrylate hydrogel structure was immersed in an aqueous solution containing 0.3M FeCl for 60 minute...

Embodiment 2

[0033] Such as figure 1 and figure 2 Shown, a kind of preparation method of 3D printing conductive hydrogel comprises the following steps:

[0034] S1. Take 40% polyethylene glycol diacrylate PEGDA with a molecular weight of 700 Daltons and 60% water to form a mixture, add 2phr photoinitiator and 0.2phr dye, and mix uniformly to obtain a photocurable resin;

[0035] S2. Use Solidworks to design the three-dimensional digital model of the honeycomb structure and convert it into an STL file format. Use the prepared value to print the designed three-dimensional digital model on a DLP 3D printer to obtain a three-dimensional support structure of polyethylene glycol diacrylate. It has a plurality of irregular pores, the spacing between the pores is greater than 100 μm;

[0036] S3. Wash the printed structure with water to remove the uncured resin on the surface, and dry it;

[0037] S4, the polyethylene glycol diacrylate hydrogel structure was immersed in an aqueous solution con...

Embodiment 3

[0041] Such as figure 1 and figure 2 Shown, a kind of preparation method of 3D printing conductive hydrogel comprises the following steps:

[0042] S1. Take 60% polyethylene glycol diacrylate PEGDA with a molecular weight of 700 Daltons and 40% water to form a mixture, add 2phr photoinitiator and 0.2phr dye, and mix uniformly to obtain a photocurable resin;

[0043] S2. Use Solidworks to design the three-dimensional digital model of the honeycomb structure and convert it into an STL file format. Use the prepared value to print the designed three-dimensional digital model on a DLP 3D printer to obtain a three-dimensional support structure of polyethylene glycol diacrylate. It has a plurality of irregular pores, the spacing between the pores is greater than 100 μm;

[0044]S3. Wash the printed structure with water to remove the uncured resin on the surface, and dry it;

[0045] S4, the polyethylene glycol diacrylate hydrogel structure was immersed in an aqueous solution cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com