Anti-dazzle electronic grade glass and manufacturing process thereof

An anti-glare, electronic-grade technology, applied in glass manufacturing equipment, manufacturing tools, glass tempering and other directions, can solve the problems of environmental hazards, affecting the manufacture and use of electronic products, low yield rate, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

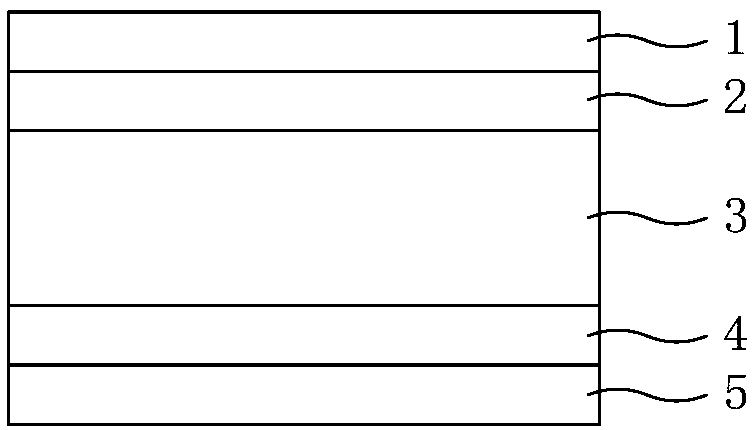

[0041] like figure 1 As shown, an anti-glare electronic grade glass includes an anti-glare layer 1, an anti-glare layer 2, a glass body 3, an ink printing layer 4 and an adhesive layer 5 arranged in sequence along the direction perpendicular to its surface.

[0042] The process for manufacturing anti-glare electronic grade glass specifically includes the following steps:

[0043] Splinter: Cut the glass body into sheets of specific size according to actual needs.

[0044] One-time cleaning: Clean the glass body to remove the dirt on the surface of the glass body and eliminate surface defects.

[0045] Sand blasting: after a certain number of abrasives are used as the medium and the solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com