Ultraviolet-blue ray excitated aluminate-base narrow-band green fluorescent powder and preparation method thereof

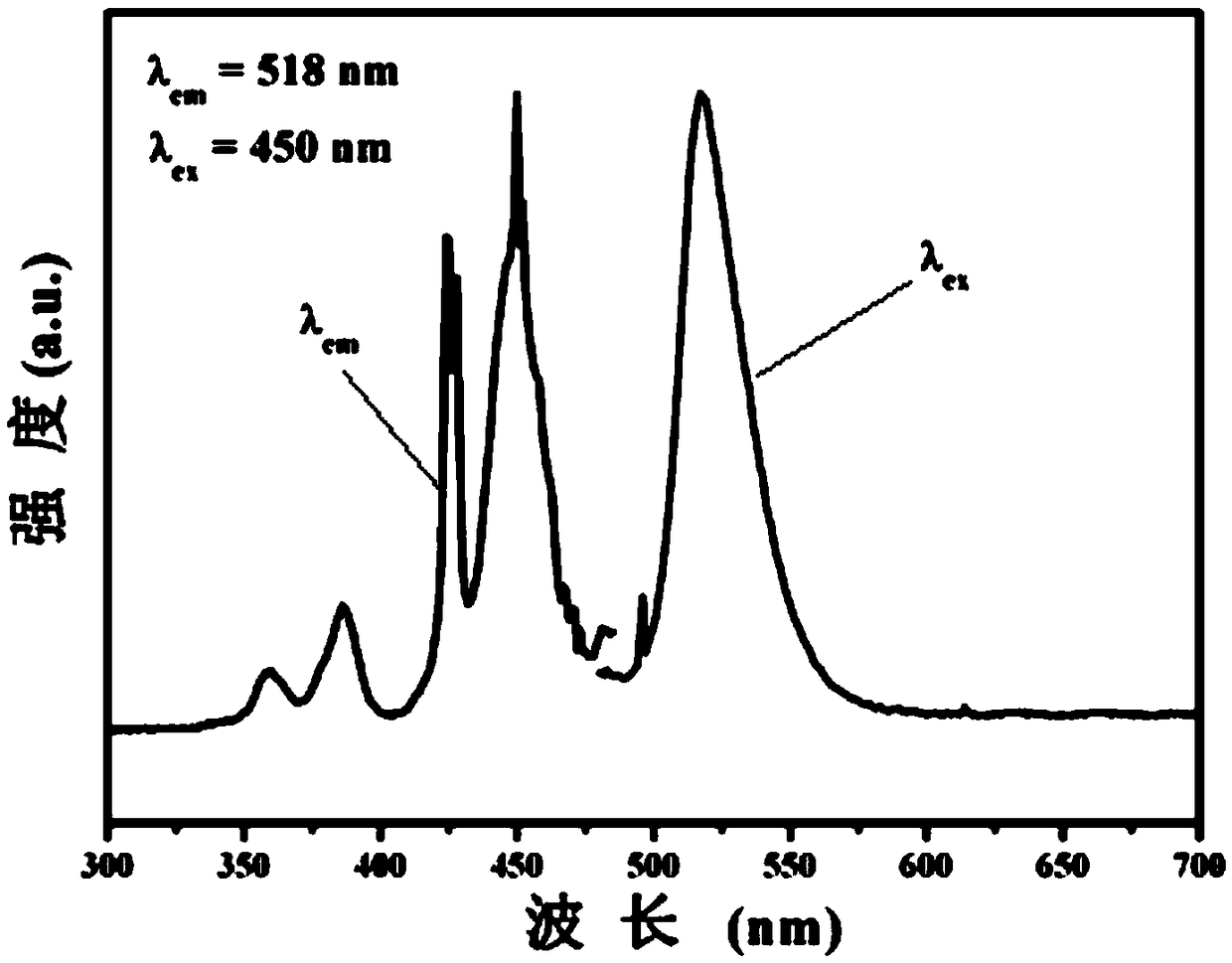

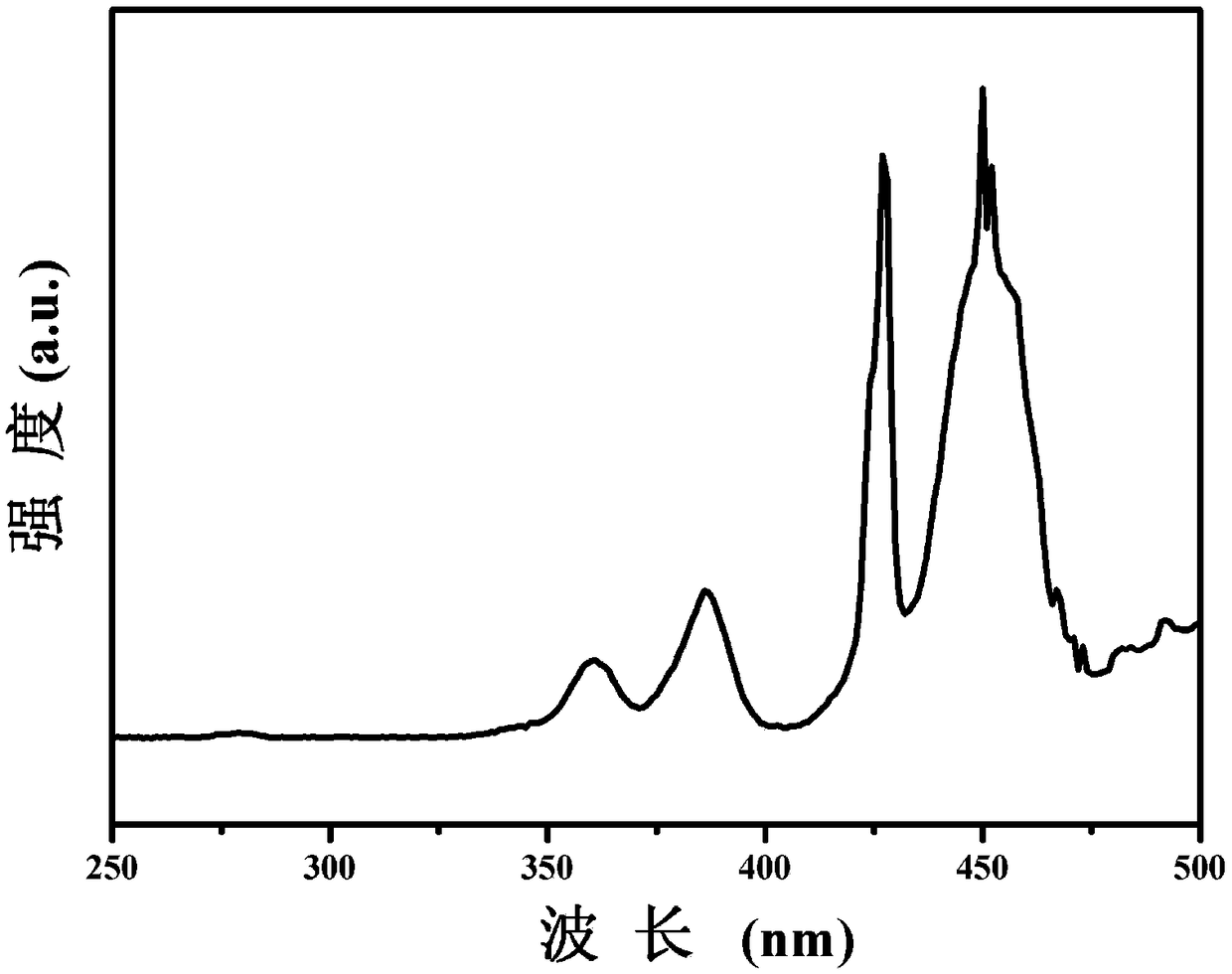

A technology of green phosphor and blue light excitation, which is applied in the field of aluminate-based narrow-band green phosphor and its preparation, which can solve the problems of limited application and achieve the effects of excellent thermal stability, low synthesis temperature and narrow emission peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

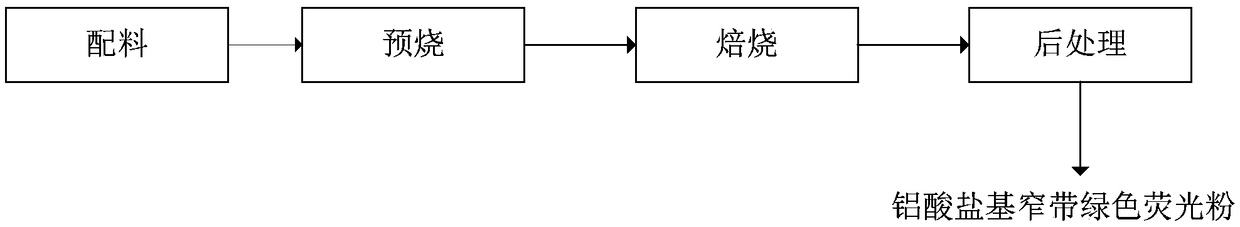

[0034] A method for preparing an aluminate-based narrow-band green fluorescent powder excited by ultraviolet-blue light, comprising the following steps:

[0035] S1. Ingredients: Weigh strontium-containing ions Sr according to the stoichiometric ratio 2+ compound, magnesium ion Mg 2+ Compounds, aluminum ions Al 3+ compounds and manganese ions Mn 2+ The compound is ground uniformly, then the co-solvent is weighed, mixed uniformly to obtain the raw material mixture, and set aside;

[0036] S2. Pre-burning: put the raw material mixture into a crucible first, then place it in a muffle furnace, and pre-fire it at 800°C for 2 to 5 hours to obtain an intermediate product;

[0037] S3. Roasting: Grind the pre-calcined intermediate product for a second time, and then roast it to 1350-1500°C under a reducing atmosphere. The intermediate product is placed in a tube furnace and roasted for 2-10 hours. The reducing atmosphere is carbon powder or N 2 -H 2 Mix the gas to get the sample;...

Embodiment 1

[0041] The present embodiment prepares chemical formula according to the following method and is Sr (Mg 0.8 mn 0.2 ) 0.25 al 11.5 o 18.5 Phosphor, ie x=0.50, y=0.25.

[0042] Ingredients: According to the above chemical formula Sr(Mg 0.8 mn 0.2 ) 0.25 al 11.5 o 18.5 The stoichiometric ratio weighs 0.1476gSrCO 3 (analytically pure), 0.0194g Mg(OH) 2 4MgCO 3 ·5H2 O (analytically pure), 0.0057g MnCO 3 (analytical pure), 0.5863g Al 2 o 3 (99.99%), and ground evenly, another weighed BaF 2 (Analytical pure) 0.0380g is used as auxiliary solvent, uniformly mixed, obtains raw material mixture;

[0043] Pre-burning: After putting the raw material mixture into the crucible, put it in a muffle furnace, and pre-fire it at 800°C for 4 hours;

[0044] Roasting: after the secondary grinding of the pre-calcined intermediate product, it is roasted in a tube furnace, in a reducing atmosphere (N 2 -H 2 Mixed gas) to 1400 ° C, the roasting time is 6h;

[0045] Post-processing: T...

Embodiment 2

[0048] The present embodiment prepares chemical formula according to the following method and is Sr (Mg 0.8 mn 0.2 ) 0.5 al 11 o 18 Phosphor, that is, x=0.50, y=0.5.

[0049] Ingredients: According to the above chemical formula Sr(Mg 0.8 mn 0.2 ) 0.5 al 11 o 18 The stoichiometric ratio weighs 0.1476g SrCO 3 (analytical pure), 0.0389g Mg(OH) 2 4MgCO 3 ·5H 2 O (analytically pure), 0.0115g MnCO 3 (analytical pure), 0.5608gAl 2 o 3 (99.99%), and ground evenly, another weighed BaF 2 (Analytical pure) 0.0380g is used as auxiliary solvent, uniformly mixed, obtains raw material mixture;

[0050] Pre-burning: After putting the raw material mixture into the crucible, put it in a muffle furnace, and pre-fire it at 800°C for 4 hours;

[0051] Roasting: after the secondary grinding of the pre-calcined intermediate product, it is roasted in a tube furnace, in a reducing atmosphere (N 2 -H 2 Mixed gas) to 1400 ° C, the roasting time is 6h;

[0052] Post-processing: Take o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com