High-stability installation structure applied to coal water slurry gasifier

A high stability, installation structure technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of safety hazards, inability to buffer, deformation, etc., to achieve the effect of improving safety, ensuring safety, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

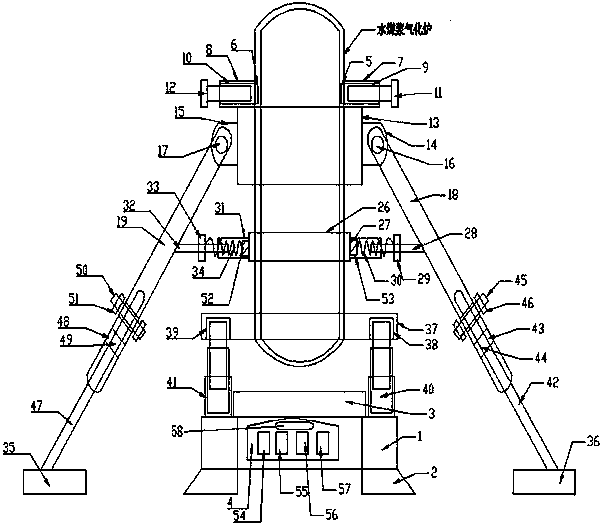

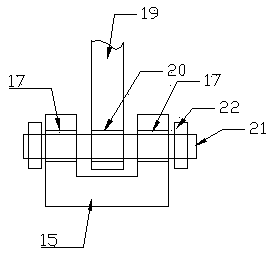

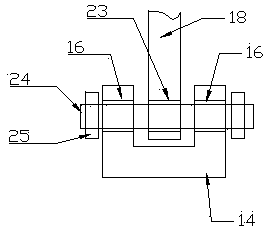

[0018] Such as figure 1 , figure 2 and image 3 A high-stability installation structure for a coal-water slurry gasifier is shown, consisting of a bottom support assembly used in conjunction with the coal-water slurry gasifier, a lifting adjustment assembly used in conjunction with the bottom support assembly, and a The upper support assembly used in conjunction with the coal-water slurry gasifier; the bottom support assembly includes the first spacer ring 3 used in conjunction with the coal-water slurry gasifier, and is matched with the first spacer ring 3 The second limit ring 1 used, and several legs 2 arranged at the bottom of the second limit ring 1; 3 The first lifting cylinder 40 and the second lifting cylinder 41 on both sides, and the lifting adjustment positioning sleeve 37 arranged at the bottom of the shell of the coal-water slurry gasifier, and are symmetrically arranged in the lifting adjustment positioning sleeve 37 and respectively connected with the first lif...

Embodiment 2

[0020] Such as figure 1 , figure 2 and image 3 A high-stability installation structure for a coal-water slurry gasifier is shown, consisting of a bottom support assembly used in conjunction with the coal-water slurry gasifier, a lifting adjustment assembly used in conjunction with the bottom support assembly, and a The upper support assembly used in conjunction with the coal-water slurry gasifier; the bottom support assembly includes the first spacer ring 3 used in conjunction with the coal-water slurry gasifier, and is matched with the first spacer ring 3 The second limit ring 1 used, and several legs 2 arranged at the bottom of the second limit ring 1; 3 The first lifting cylinder 40 and the second lifting cylinder 41 on both sides, and the lifting adjustment positioning sleeve 37 arranged at the bottom of the shell of the coal-water slurry gasifier, and are symmetrically arranged in the lifting adjustment positioning sleeve 37 and respectively connected with the first l...

Embodiment 3

[0022] Such as figure 1 , figure 2 and image 3A high-stability installation structure for a coal-water slurry gasifier is shown, consisting of a bottom support assembly used in conjunction with the coal-water slurry gasifier, a lifting adjustment assembly used in conjunction with the bottom support assembly, and a The upper support assembly used in conjunction with the coal-water slurry gasifier; the bottom support assembly includes the first spacer ring 3 used in conjunction with the coal-water slurry gasifier, and is matched with the first spacer ring 3 The second limit ring 1 used, and several legs 2 arranged at the bottom of the second limit ring 1; 3 The first lifting cylinder 40 and the second lifting cylinder 41 on both sides, and the lifting adjustment positioning sleeve 37 arranged at the bottom of the shell of the coal-water slurry gasifier, and are symmetrically arranged in the lifting adjustment positioning sleeve 37 and respectively connected with the first li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com