Integrated composite wall decorative building block and construction method thereof

A composite wall and construction method technology, applied to walls, building components, buildings, etc., can solve the problems of unsatisfactory impermeability, long time, high construction labor costs, etc., and achieve efficient and fast construction methods, good thermal insulation and sound insulation performance , The effect of low construction labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

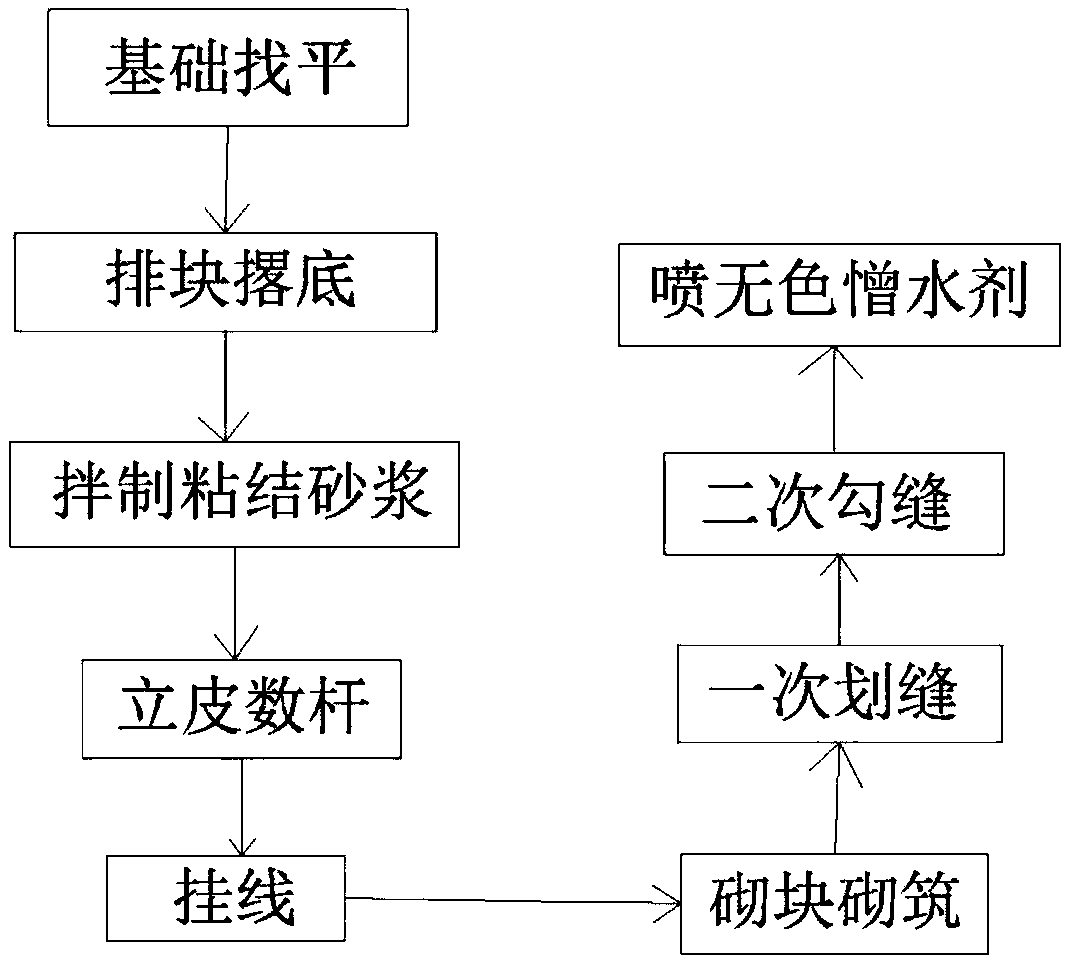

[0027] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

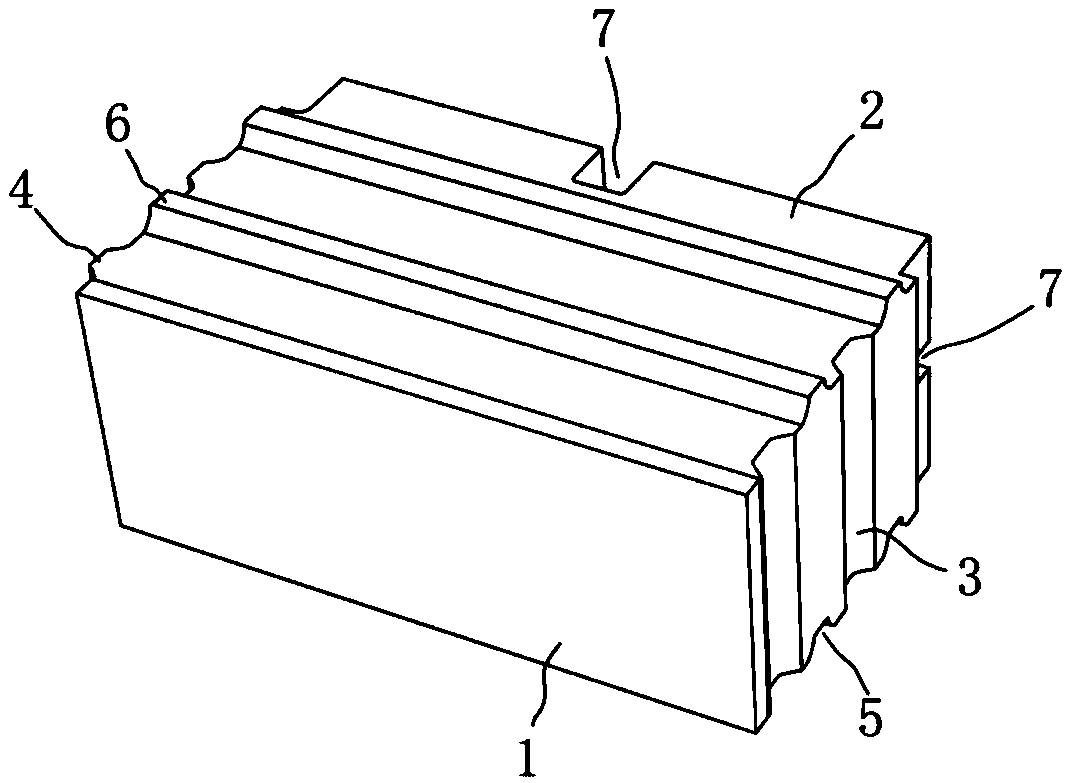

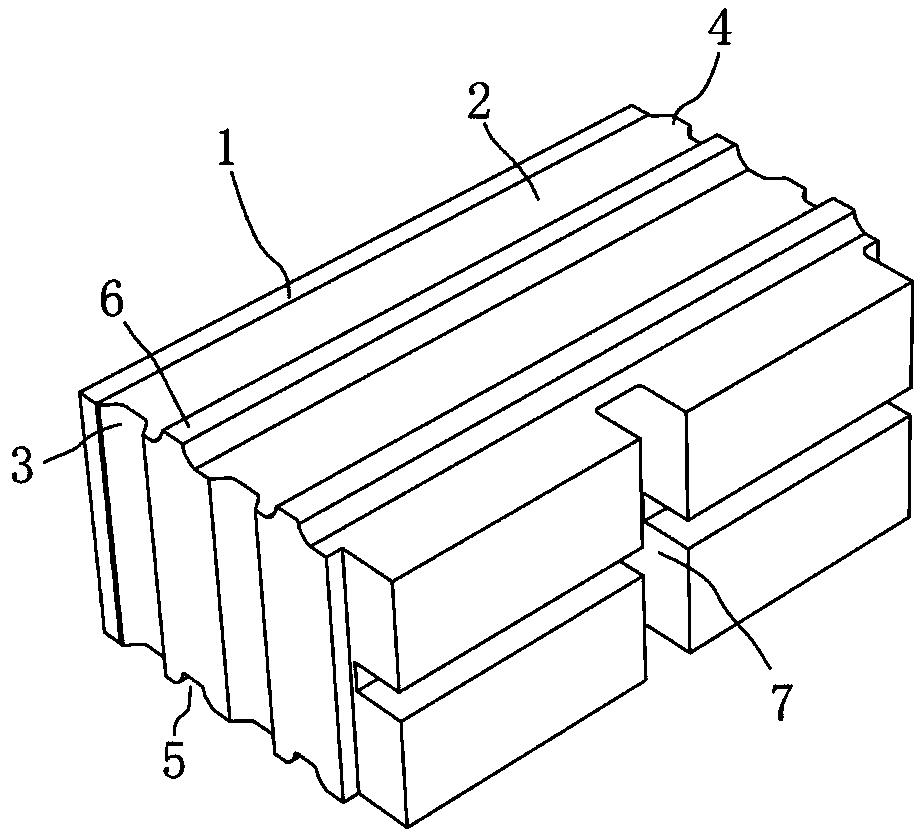

[0028] Such as Figure 1-2 Shown is an integrated composite wall decorative block of the present invention, comprising a facing layer 1 and a brick body 2, the facing layer 1 and the brick body 2 are foamed and formed by mixing foamed cement and ceramsite, and the facing layer 1 One-piece foam molding is formed on the front of the brick body 2, one side of the left and right sides of the brick body 2 is formed with a longitudinal splicing groove 3, and the other side of the left and right sides of the brick body 2 is formed with a longitudinal splicing convex strip 4, and the longitudinal splicing The groove 3 corresponds to the longitudinal splicing convex strip 4, the bottom surface of the brick body 2 is formed with a horizontal splicing groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com