Rod breaker handle

A handle and drill pipe technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of hand squeeze, affecting the working efficiency of the drilling rig, the service life of the drill pipe, and the safety hazards of operators, so as to achieve a simple and convenient operation process and reduce The effect of labor intensity and safety index improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings:

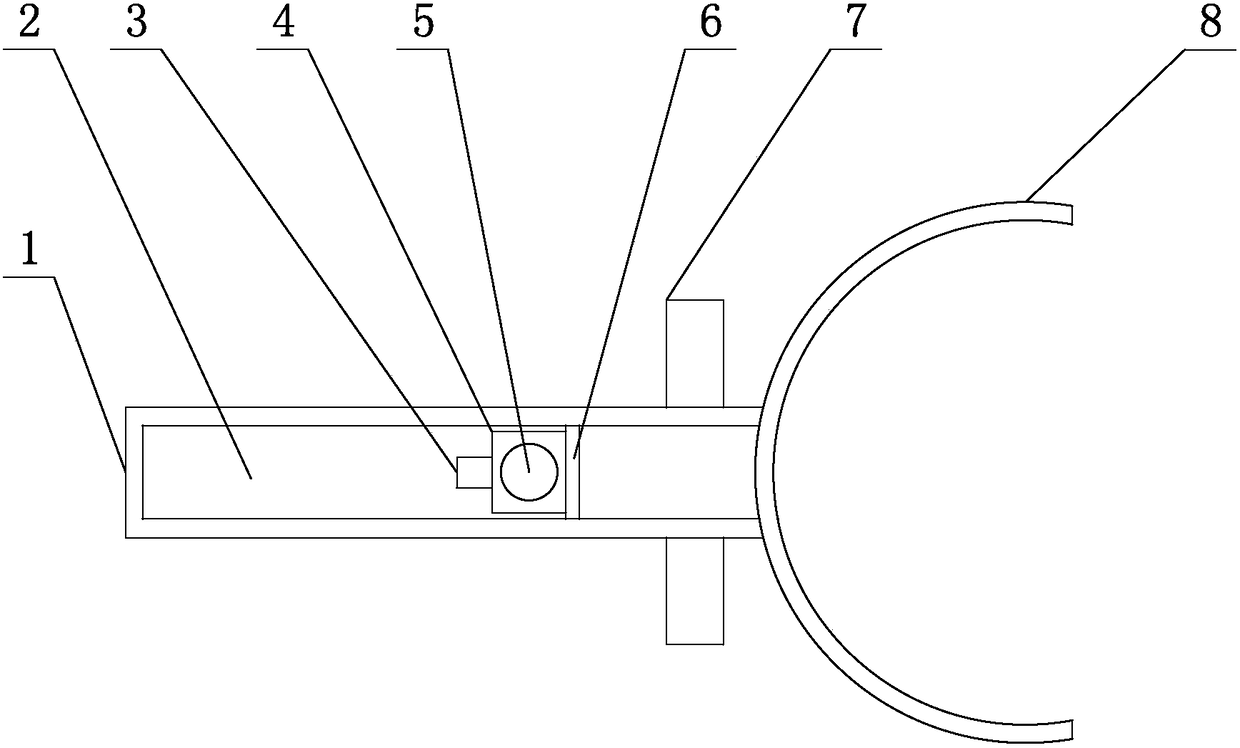

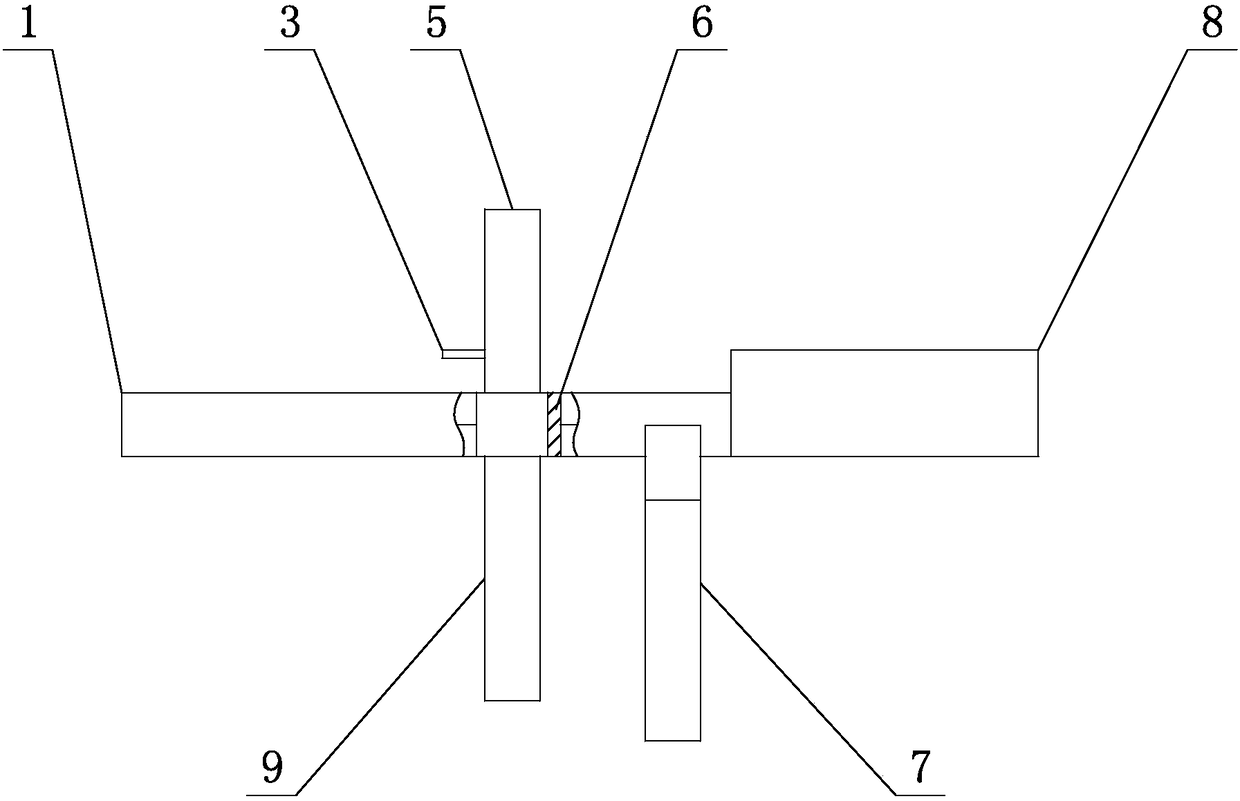

[0014] Such as figure 1 with figure 2 , The drill pipe handle of the present invention includes a semi-circular arc support body 8 and a strip plate 1. One end of the strip plate 1 is fixedly connected to the middle position of the outer wall of the semi-circular arc support body 8; the strip plate 1 is provided with There is a sliding rail 2 with a sliding block 4 slidably fitted on the sliding rail 2, a column 5 is arranged above the sliding block 4, a pulling handle 9 is arranged below the sliding block 4, and a supporting handle 7 is arranged below the strip plate 1.

[0015] In this embodiment: a baffle 6 is provided on the slide rail 2, and the baffle 6 is fixed to the slide rail 2 by bolts; a load-bearing support plate 3 is provided on the column 5, and the load-bearing support plate 3 is higher than the strip plate 1 and supports the load The height of the plate 3 and the semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com