Diaphragm sleeve and steam turbine

A diaphragm sleeve and steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of large axial size and complex structure, and achieve the goal of reducing axial size, simplifying structure, and reducing manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

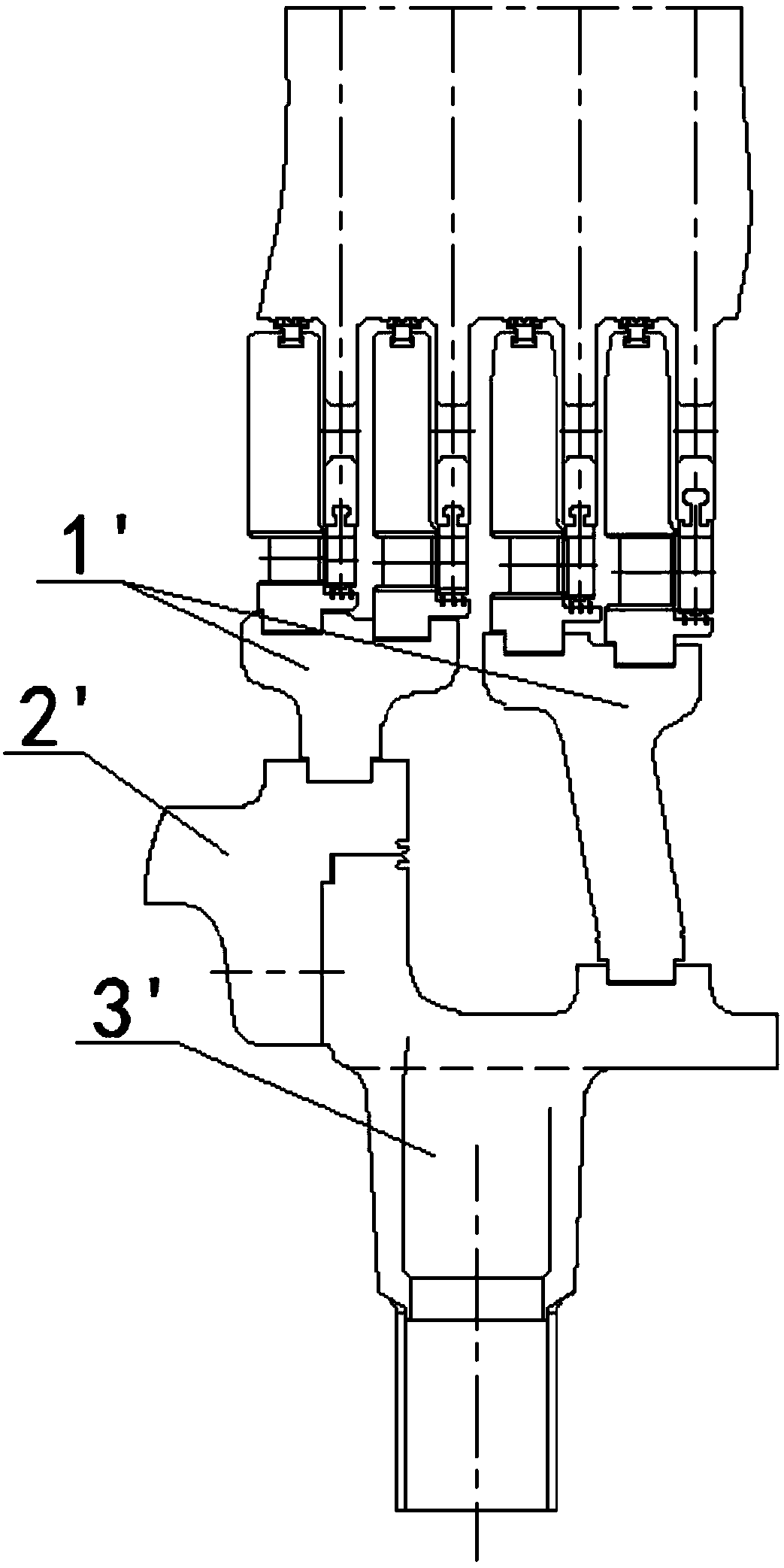

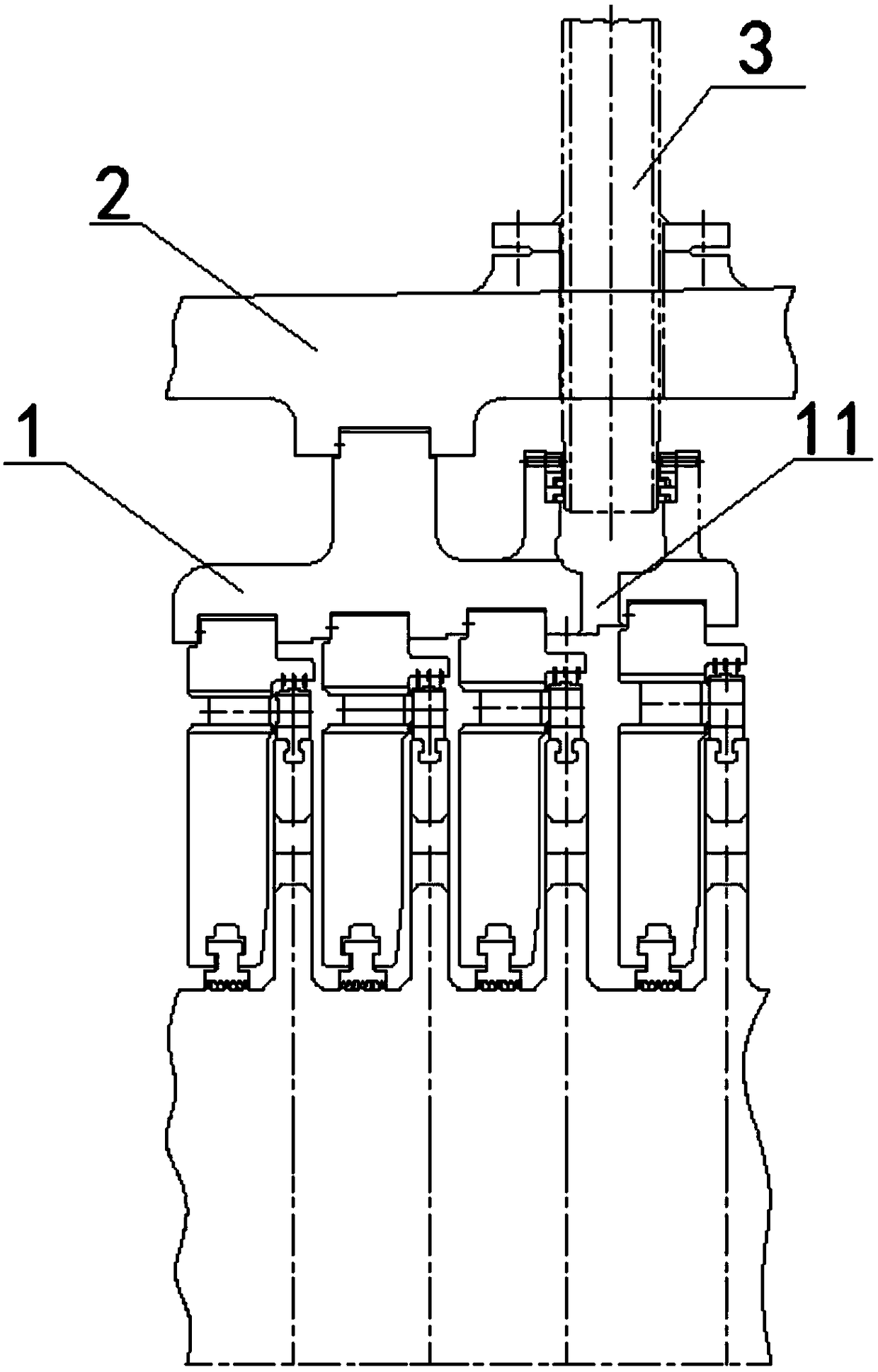

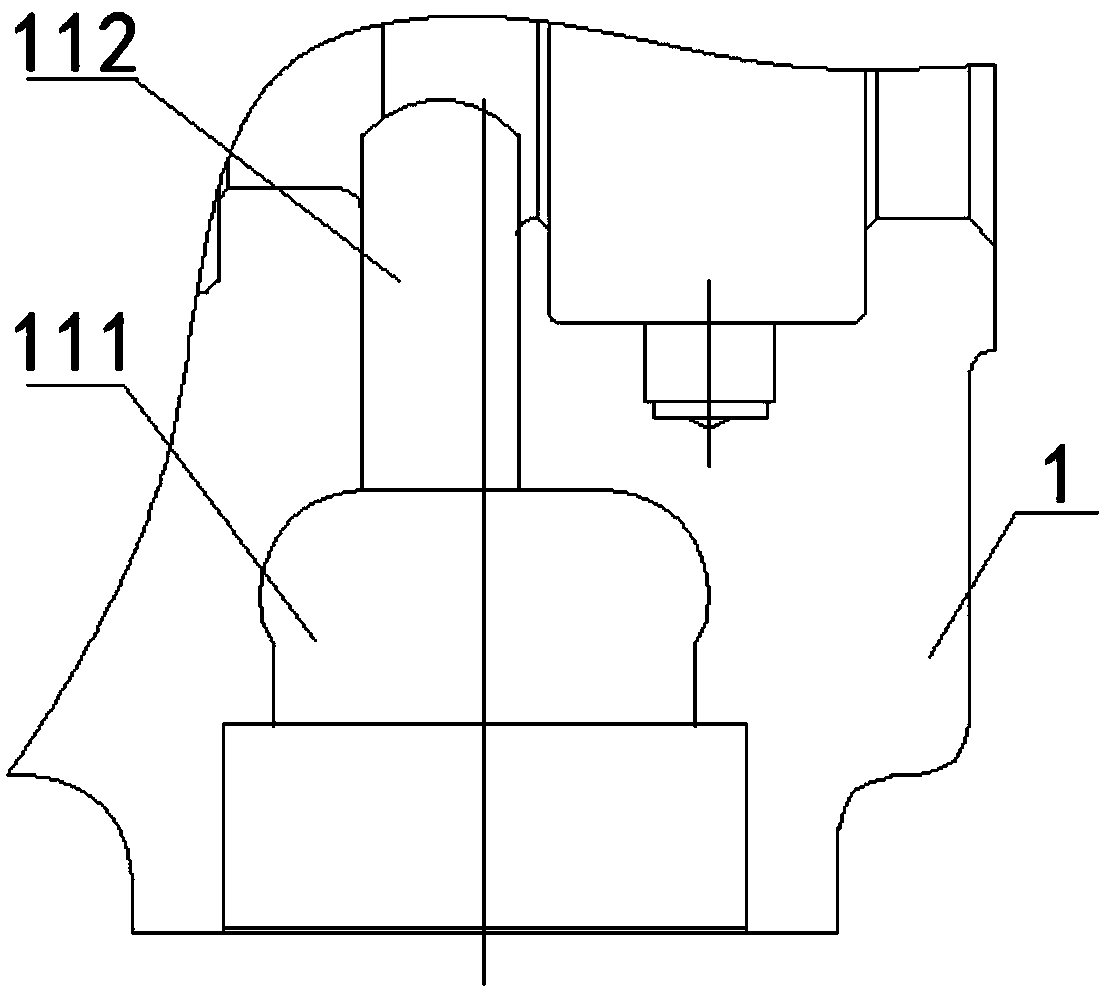

[0033] The partition cover provided in this embodiment, such as Figure 2 to Figure 5 As shown, the first partition cover 1 is included; the inner wall of the first partition cover 1 is provided with a plurality of partition installation grooves, and the side wall of the first partition cover 1 is provided with a steam extraction hollow mechanism. The two ends of the structure 11 are respectively arranged through the side wall of the first baffle cover 1 , and the steam extraction hollow structure 11 is located between two adjacent baffle installation grooves.

[0034] Wherein, the shape of the hollow air pumping structure is determined according to the size of the hole obtained through the calculation of the flow, such as any suitable shape such as column, arc or cavity, and the two ends of the air pumping hollow structure penetrate through the side wall of the first partition sleeve 1 respectively. Setting, the inner wall and the outer wall of the first partition cover 1 can...

Embodiment 2

[0051] The steam turbine provided by the present embodiment comprises a cylinder 2, a front steam seal, a connecting pipe 3 and a partition cover of the present invention; the partition cover is fixed on the inner wall of the cylinder 2, and one end of the connecting pipe 3 communicates with the steam extraction hollow structure 11, The other end passes through the cylinder 2 and communicates with the front steam seal.

[0052] Wherein, the air pumping hollow structure can be in any suitable shape, such as any suitable shape such as columnar, arc-shaped or cavity-shaped, and the two ends of the air pumping hollow structure are respectively set through the side wall of the first partition cover 1, which can be used The inner wall and the outer wall of a partition cover 1 are connected, so that the steam extracted from the front steam seal enters between the two partitions of the partition cover through the connecting pipe 3 on the cylinder 2 and the steam extraction hollow struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com