Microchannel gas-liquid separation evaporator device based on distribution recovery channel

A gas-liquid separation and evaporator technology, used in electrical components, indirect heat exchangers, electrical equipment structural parts, etc., can solve the problems of poor heat exchange performance, easy to dry out, uneven liquid replenishment, etc., to ensure sufficient liquid replenishment. , to avoid the effect of local drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

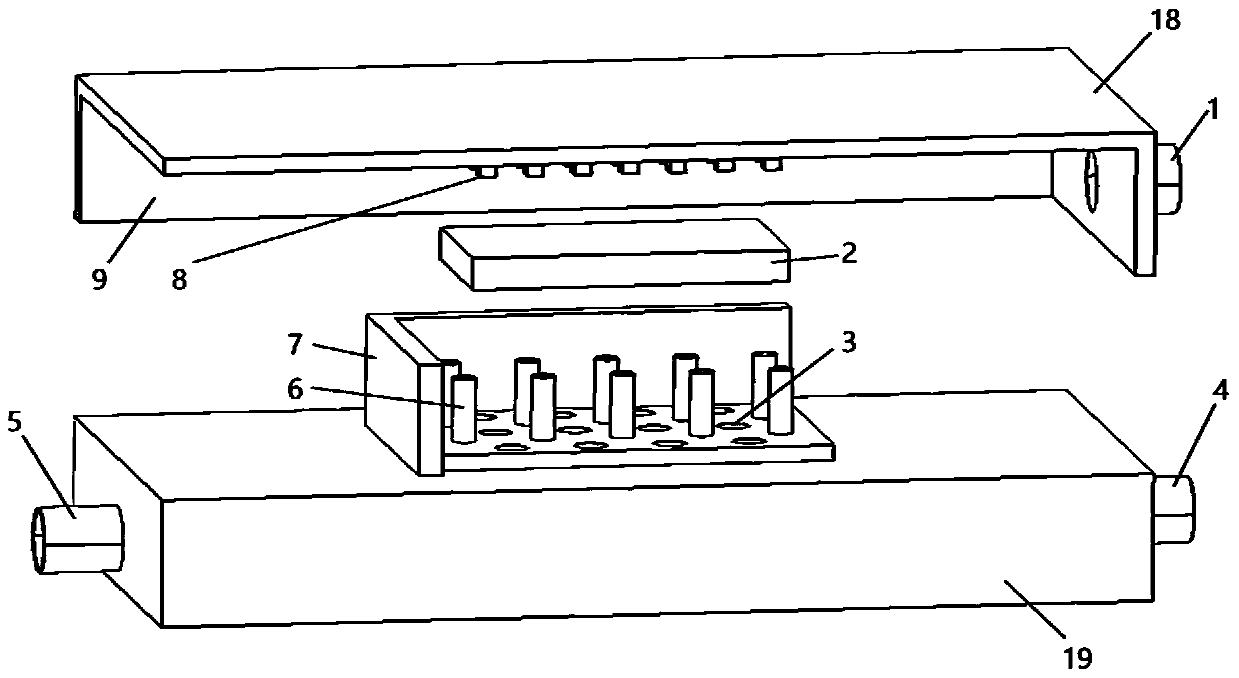

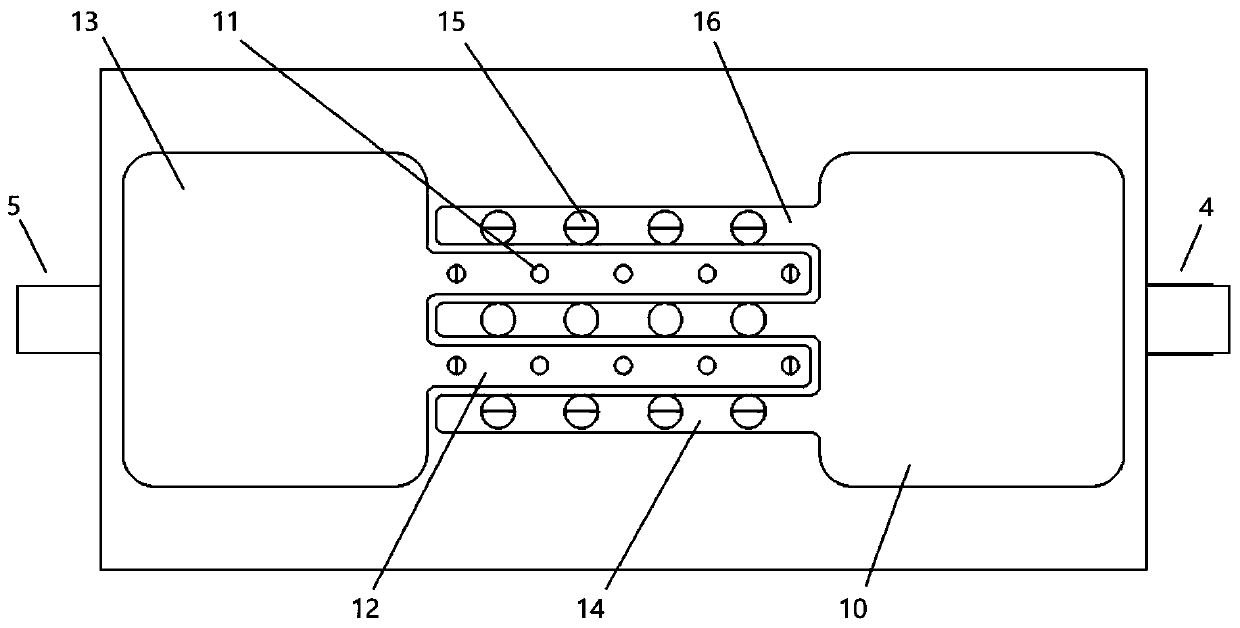

[0024] Such as figure 1 As shown, it is a gas-liquid separation evaporator device involved in this embodiment, comprising: a microchannel structure 9 and a distribution and recovery structure 19, the microchannel structure 9 is provided with a gas phase outlet 1, and the distribution and recovery structure 19 is respectively provided with a working The mass inlet 5 and the liquid phase outlet 4, wherein: the microchannel structure 9 and the distribution and recovery structure 19 are separated by a wire mesh 2.

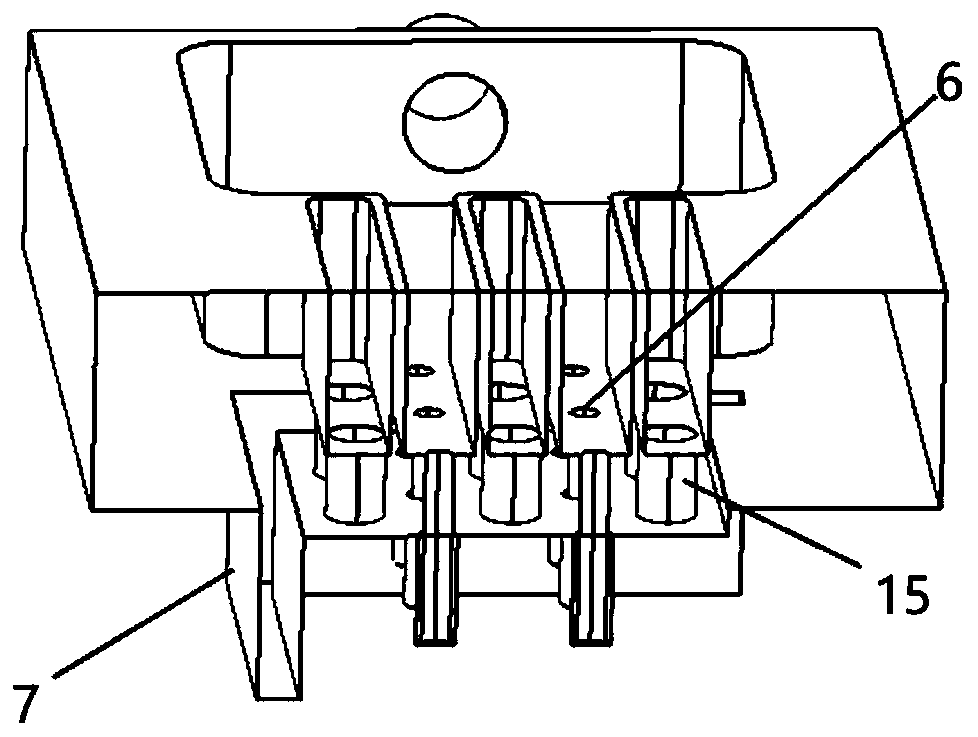

[0025] The microchannel structure 9 includes: a heating base 18, pin ribs 8 and a sintering surface 17, wherein: the pin ribs 8 are arranged in an array on the heating base 18, the sintering surface 17 covers the pin ribs 8 and the heating base 18, and the gas phase The outlet 1 is located on the side of the microchannel structure 9 .

[0026] The tops of the pin ribs 8 are connected to the wire mesh 2 .

[0027] The heating base 18 and the pin fins 8 are preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com