Method for leveling measurement of opposite observation by compound level with double observation units

A composite level and leveling technology, applied in the field of measurement, can solve the problems of inaccurate correction of the i-angle of the observation unit, erection of the level, and the energy and time of the surveyors, so as to overcome the instability of the dual-system opposite measurement and ensure reliability. , the effect of improving fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

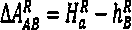

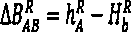

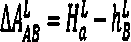

[0029] The dual-observation-unit compound level of the present invention is carried out according to the following steps:

[0030] a. Carry out parameter information measurement to the dual-observation unit composite level A and the dual-observation unit composite level B respectively having the first electronic level and the second electronic level simultaneously; The structure is exactly the same, both have a first electronic level and a second electronic level, the first electronic level and the second electronic level can be set on the scale on the left and right or up and down, and the others are the same as the existing composite level;

[0031] b. Same as the prior art, determine the starting and ending measuring points of the leveling section, and place the dual-observation unit compound level A at the initial measuring point, and the dual-observation unit composite level B at the adjacent measuring point;

[0032] c. Surveyor A and surveyor B operate the dual-observat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com