Calibration method and device for error of included angle between ccd target face and mounting and positioning face based on leaked radiation imaging

A technology of installation positioning and radiation imaging, applied in the field of optical calibration, can solve the problems of difficult to ensure the accuracy of the instrument, difficult to distinguish, low accuracy, etc., to achieve the effect of improving detection contrast and accuracy, convenient detection and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings.

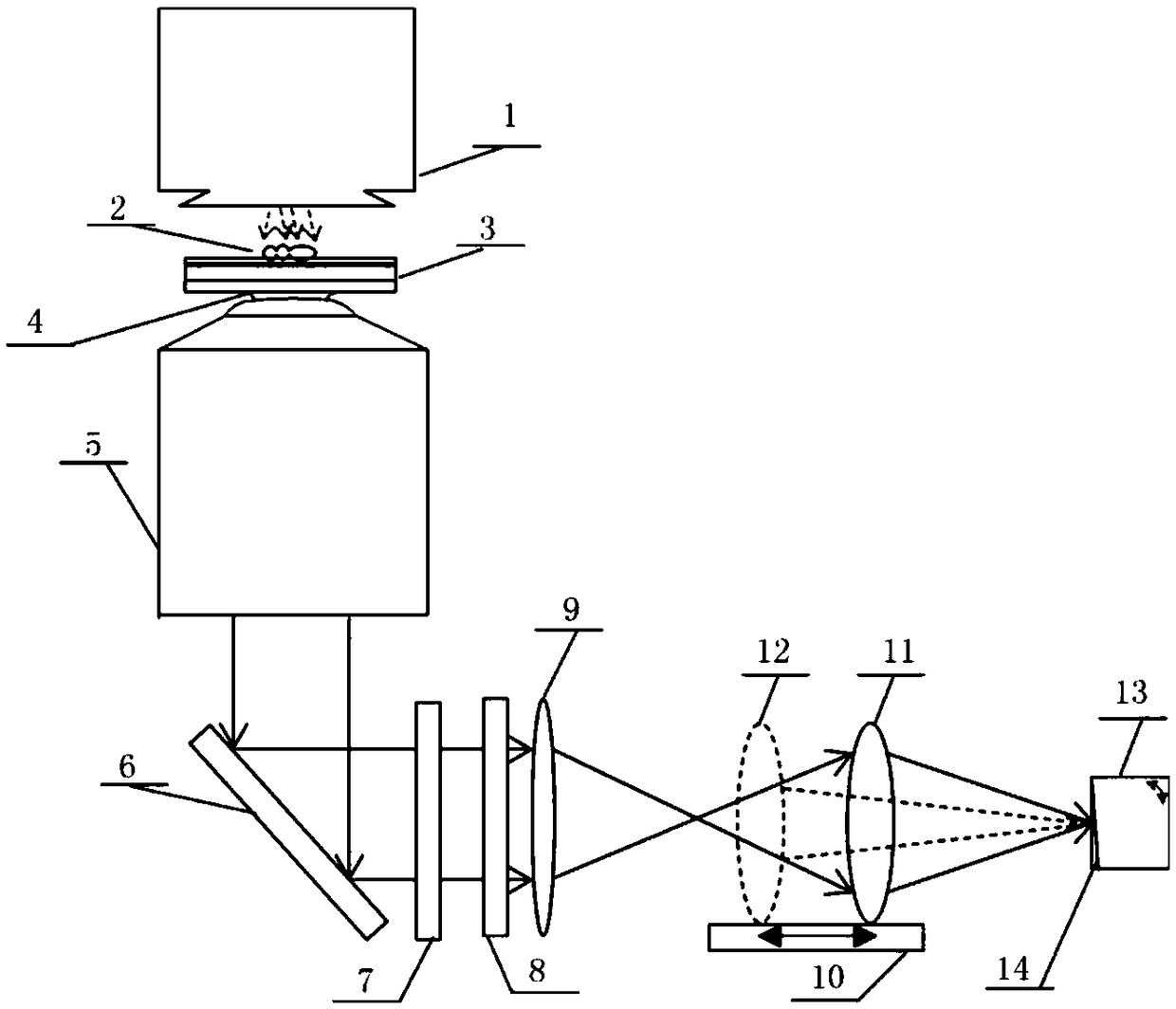

[0030] combine figure 1 , a calibration device based on the angle error between the CCD target surface and the installation positioning surface based on leaked radiation imaging, the device includes an illumination light source 1, a fluorescent substance to be measured 2, a metal layer-containing chip substrate 3, a refractive index matching oil 4, a display Micro-objective lens 5, reflective mirror 6, polarizing element group 7, filter 8, condenser lens 9, horizontal moving axis 10, imaging lens 11 and ccd image sensor 13, the illumination light source 1, the metal layer-containing chip substrate 3, The refractive index matching oil 4 and the microscope objective lens 5 are arranged coaxially in sequence, the polarizing element group 7, the filter 8, the condenser lens 9, the imaging lens 11 and the ccd image sensor 13 are arranged coaxially in sequence, and the fluores...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com