Detection device for photocatalytic degradation of titanium dioxide and detection method thereof

A detection device and titanium dioxide technology, which is applied in the direction of detection of element existence through oxidation, measurement device, chemical method analysis, etc., can solve the problems of complex operation and low nitrogen elution results, and achieve accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

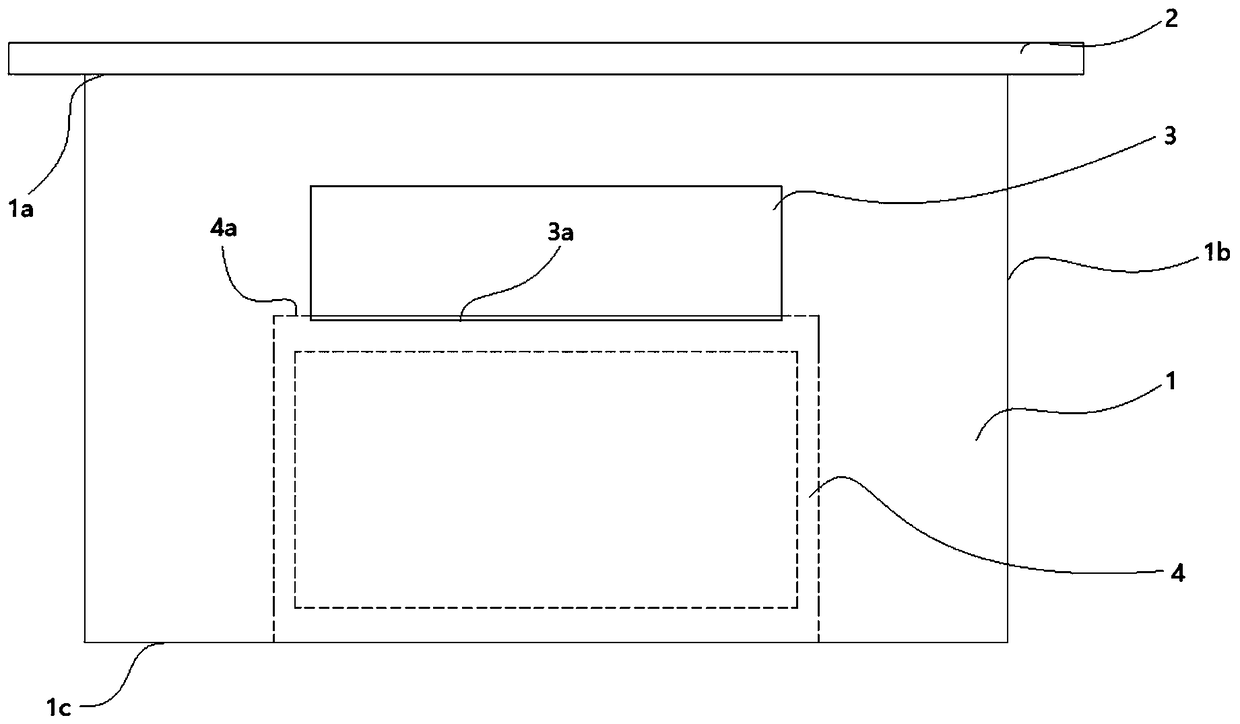

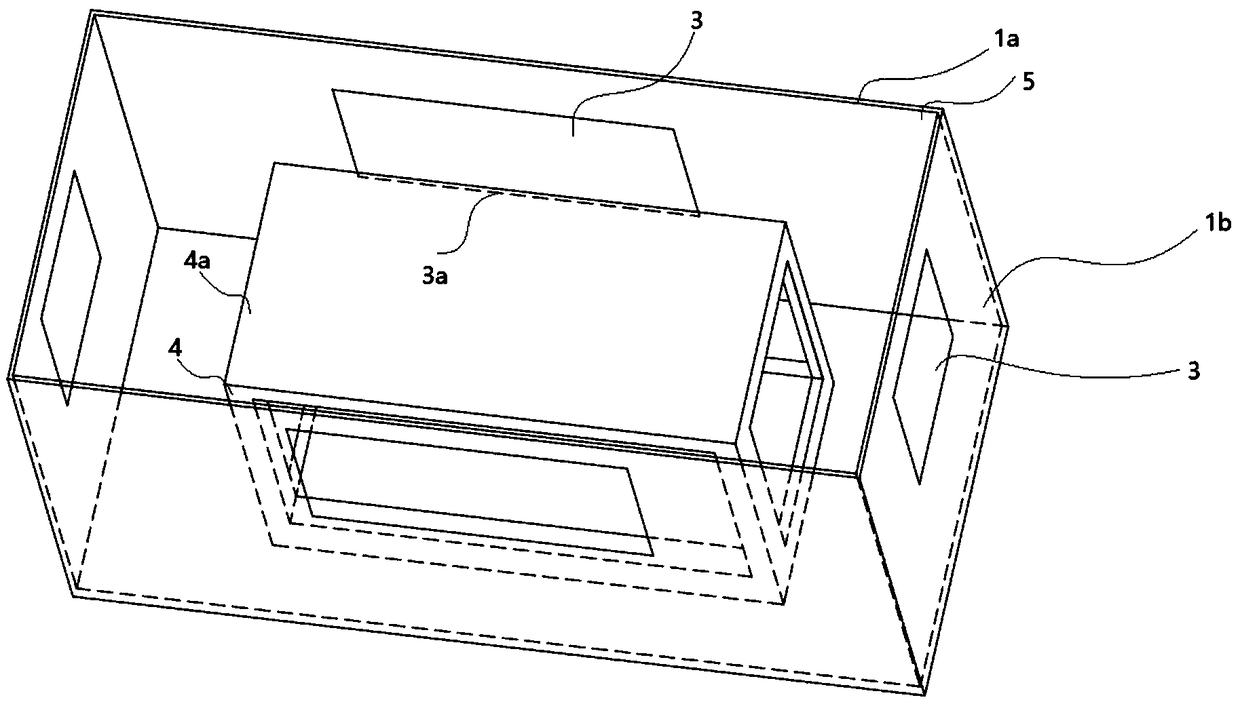

[0034] Such as figure 1 As shown, Embodiment 1 discloses a specific embodiment of a titanium dioxide photocatalytic degradation detection device, including: a hollow shell 1 and a baffle 2, and the hollow shell 1 is provided with a device for taking and placing the tested sample. The access port 5 and the hollow shell 1 are also provided with a vent hole 3 for air circulation, and the vent hole 3 communicates the inside of the hollow shell 1 with the outside of the hollow shell 1 . The baffle plate 2 is arranged at the access opening 5 to cover the access opening 5. In this embodiment, the ventilation hole 3 is a rectangular hole. Of course, in other specific embodiments, it can also be a circular hole or an oval hole. and other arbitrary shapes, which will not be repeated here.

[0035] Specifically, such as figure 2 As shown, the hollow shell 1 is a cuboid, the first end surface 1a of the hollow shell 1 is an open end, and the open end constitutes the access opening 5, an...

Embodiment 2

[0039] Such as figure 1 and figure 2 As shown, embodiment 2 is based on embodiment 1, and the number of vent holes 3 in embodiment 2 is four. As shown in the figure, the connection end surface 1b is divided into four surfaces, each surface is provided with a vent hole 3, and the heights of the four vent holes 3 are all equal. Setting a plurality of ventilation holes 3 can improve the air circulation between the inside and the outside of the hollow shell 1, so that the tested sample is in better contact with the air, so that the elution amount of nitrogen of the tested sample is closer to that of the actual nitrogen. Elution volume.

[0040] better, such as figure 2 As shown, the hollow shell 1 is also provided with a placement bracket 4 for supporting the tested sample. The tested sample is placed on the placement surface 4a of the placed bracket 4, and the vent hole 3 is a rectangular hole. When the tested sample When the sample is placed on the placement surface 4a, the ...

Embodiment 3

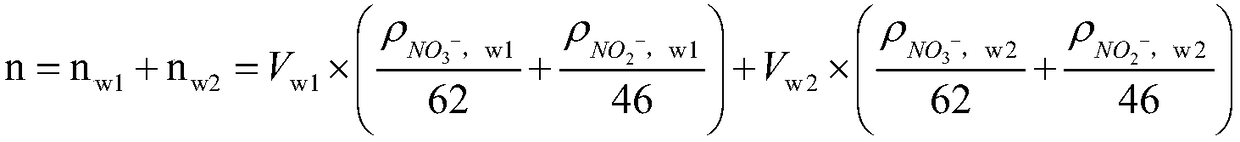

[0042] Such as figure 1 and figure 2 As shown, embodiment 3 discloses a detection method, the application of any titanium dioxide photocatalytic degradation detection device in embodiments 1 to 2, specifically includes the following steps:

[0043] S1: Apply the nano-titanium dioxide material evenly on the brick to obtain the tested sample. In this embodiment, only the nano-titanium dioxide material is evenly coated on one side of the brick. In other specific embodiments, it can also be coated The two sides, three sides, etc. of the bricks will not be repeated here;

[0044] S2: Place the sample to be tested inside the hollow shell 1 so that the side coated with the nano-titanium dioxide material faces up, and place the sample to be tested together with the hollow shell 1 at the testing site;

[0045] S3: Take out the tested sample from the hollow shell 1 after the preset time has elapsed. The preset time can be any value from 14 to 40 days, which is determined according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com